A method for separating arsenic and selenium from copper anode slime alkaline leaching solution

A technology for copper anode slime and leachate is applied in the field of separation of arsenic and selenium, which can solve the problems of sulfur dioxide pollution, long process, consume a lot of acid, etc., and achieve the effects of short process process, good separation effect and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

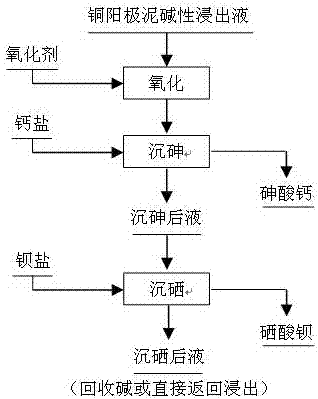

[0030] A method for separating arsenic and selenium from copper anode slime alkaline leaching solution of the present invention, its technological process is as follows figure 1 shown, including the following steps:

[0031] 1) Oxidation: take 1L of alkaline leaching solution (As: 2g / L, Se: 2g / L, OH - : 0.5mol / L), ozone was introduced at a stirring speed of 200r / min and the temperature was kept at 25°C until the potential of the copper anode slime alkaline leaching solution tended to be stable, and the oxidized copper anode slime alkaline leaching solution was obtained.

[0032] 2) Precipitation of arsenic: Add calcium hydroxide (the molar ratio of calcium hydroxide to arsenic in the alkaline leaching solution is 3) to the oxidized copper anode slime alkaline leaching solution, stir at a stirring speed of 200r / min for 1h, and filter Finally, calcium arsenate precipitate and arsenic solution are obtained. After testing, the arsenic concentration in the liquid after arsenic pr...

Embodiment 2

[0035] A method for separating arsenic and selenium from copper anode slime alkaline leaching solution of the present invention, its technological process is as follows figure 1 shown, including the following steps:

[0036] 1) Oxidation: Take 1L of alkaline leaching solution (As: 10g / L, Se: 15g / L, OH - : 1mol / L), ozone was introduced at a stirring speed of 300r / min and the temperature was kept at 40°C until the potential of the copper anode slime alkaline leaching solution tended to be stable, and the oxidized copper anode slime alkaline leaching solution was obtained.

[0037] 2) Precipitation of arsenic: Add calcium hydroxide (the molar ratio of calcium hydroxide to arsenic element in the alkaline leaching solution is 6) to the oxidized copper anode slime alkaline leaching solution, stir at a stirring speed of 300r / min for 3 hours, and filter Finally, calcium arsenate precipitate and arsenic solution are obtained. After testing, the arsenic concentration in the solution a...

Embodiment 3

[0040] A method for separating arsenic and selenium from copper anode slime alkaline leaching solution of the present invention, its technological process is as follows figure 1 shown, including the following steps:

[0041] 1) Oxidation: Take 1L of alkaline leaching solution (As: 25g / L, Se: 20g / L, OH- : 3mol / L), ozone was introduced at a stirring speed of 500r / min and the temperature was maintained at 60°C until the potential of the copper anode slime alkaline leaching solution became stable, and the oxidized copper anode slime alkaline leaching solution was obtained.

[0042] 2) Precipitation of arsenic: Add calcium hydroxide (the molar ratio of calcium hydroxide to arsenic in the alkaline leaching solution is 9) to the oxidized copper anode slime alkaline leaching solution, and stir at a stirring speed of 500r / min for 6h, filter Finally, calcium arsenate precipitate and arsenic solution are obtained. After testing, the concentration of arsenic in the solution after arsenic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com