Method for Extracting Rubidium from Salt Lake Brine

A salt lake brine and extraction technology, which is applied in the direction of improving process efficiency to achieve the effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

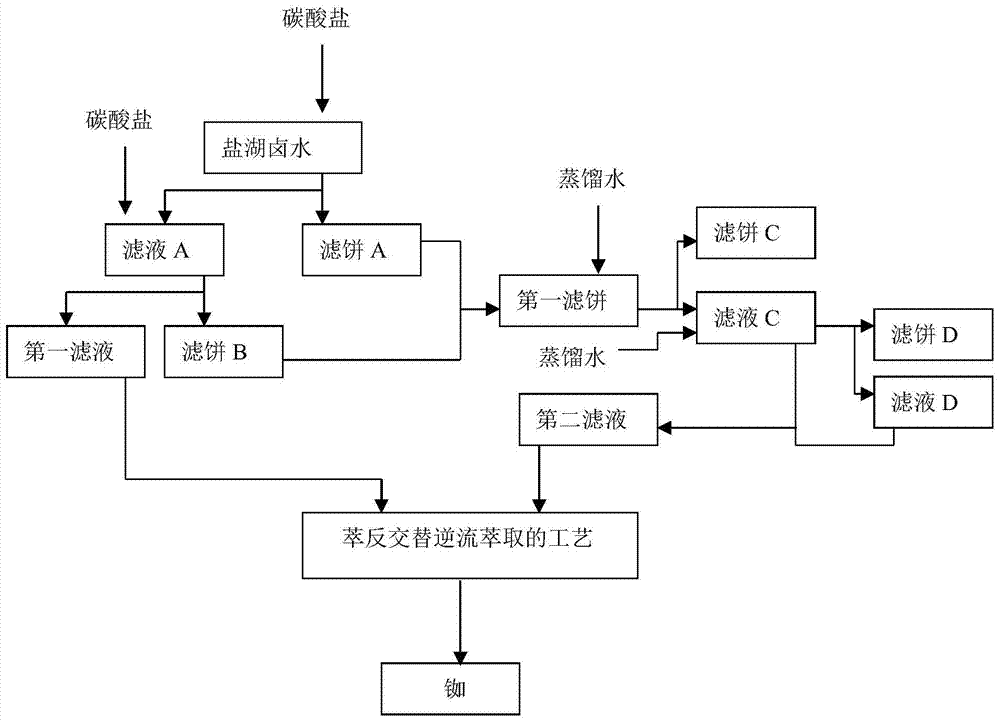

Method used

Image

Examples

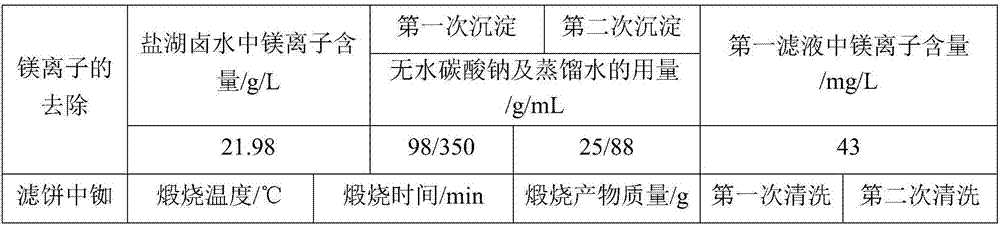

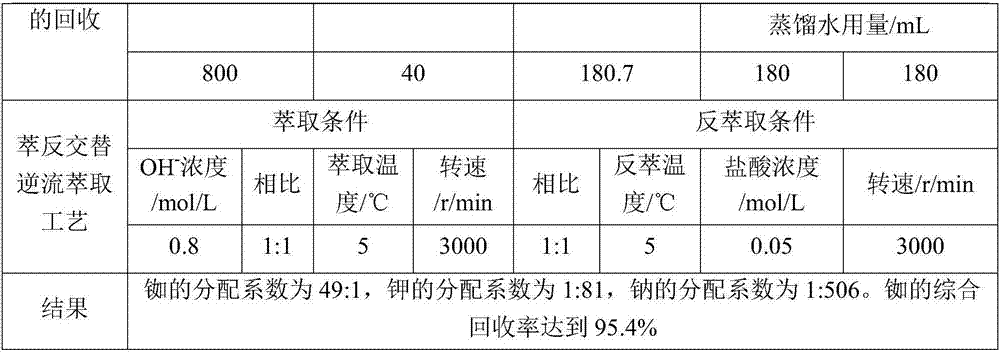

Embodiment 1

[0045]Dissolve 98g of anhydrous sodium carbonate in 350mL of distilled water, slowly add to 1L of salt lake brine sample (magnesium content is 21.98g / L), stir for 10min, filter, and collect filtrate A and filter cake A respectively.

[0046] Weigh 25 g of anhydrous sodium carbonate and dissolve it in 88 mL of distilled water, slowly add it to filtrate 1, stir for 10 min, filter, and collect the first filtrate and filter cake B respectively. The content of magnesium in the collected first filtrate was 43mg / L.

[0047] The first and second precipitated filter cakes A and B were combined into the first filter cake, dried and heated in a muffle furnace at 800°C for 40 minutes, with a total weight of 180.7g. After taking it out and cooling it, add 180mL distilled water to wash once, filter, and collect filtrate C and filter cake C respectively.

[0048] Add 180 mL of distilled water to the filter cake C to wash it twice, filter, and collect the filtrate D and filter cake D respect...

Embodiment 2

[0056] The operating steps of the present embodiment are similar to those of Example 1, and the process parameters are as shown in Table 2:

[0057] The process parameter and result thereof of table 2 embodiment 2

[0058]

Embodiment 3

[0060] The operating steps of the present embodiment are similar to those of Example 1, and the process parameters are as shown in Table 3:

[0061] The process parameter and the result thereof of table 3 embodiment 3

[0062]

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com