A method for porous media adsorption and separation of vanadium resources in vanadium slag

A porous medium, adsorption and separation technology, applied in the direction of improving process efficiency, etc., can solve the problems that the solid phase of vanadium-containing spinel in the vanadium slag can not be separated by high gravity, high requirements for high gravity equipment, etc., to solve the problem of comprehensive utilization, The effect of less environmental pollution and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

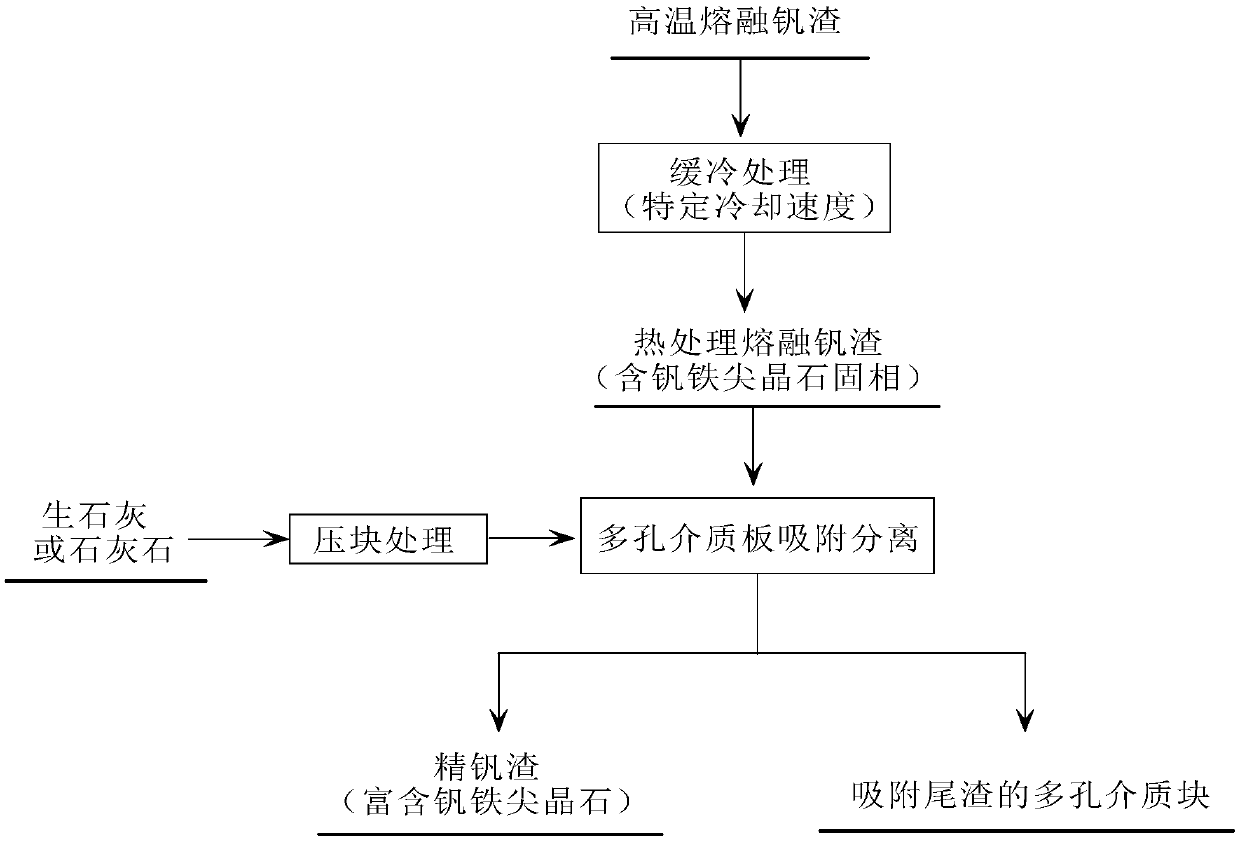

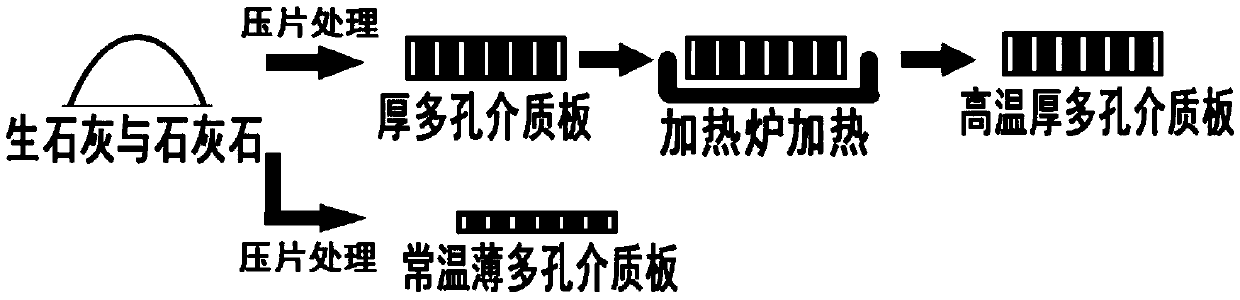

[0029] (1) Preparation and treatment of porous media plates

[0030] Preparation method 1: crush quicklime or limestone and then sieve to obtain particles with a size between 10 and 60 meshes, and then briquette to obtain a thick porous medium plate, and heat the medium plate to 600-1200 in a heating furnace. ℃ and keep warm. The thickness of the porous medium plate is 60-150 mm, and the hole diameter is 30-80 microns.

[0031] Preparation method 2: crush quicklime or limestone and then sieve to obtain particles with a size between 10 and 60 meshes, and then briquetting to obtain a thin porous medium plate at room temperature, which is stored at room temperature for later use. The thickness of the porous medium plate is 20-60 millimeters, and the hole diameter is 60-100 microns.

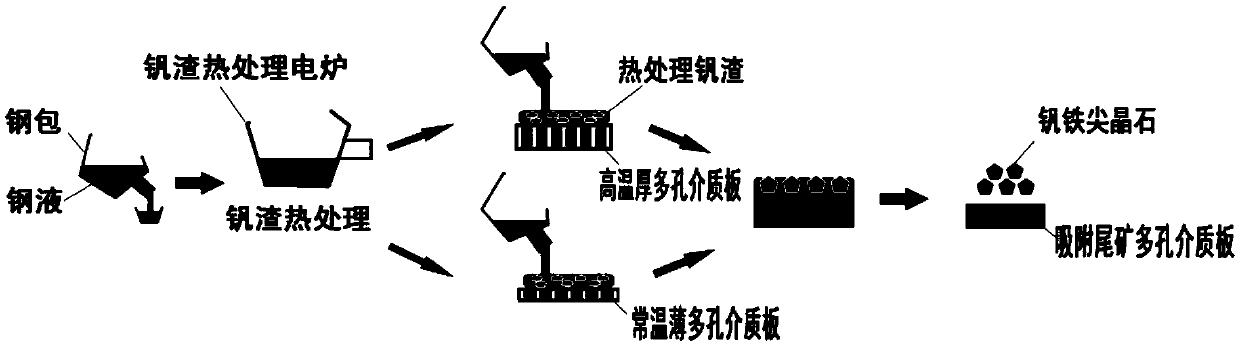

[0032] (2) Selective precipitation and growth of vanadium-rich phase in vanadium slag

[0033] In order to ensure efficient adsorption and separation of vanadium-containing slag, it is first neces...

Embodiment 1

[0040] A vanadium-containing steel slag, after testing, its chemical composition is: 6.8% CaO, 20.5% SiO 2 , 1.2% Al 2 O3, 5.8% MgO, 8.2% MnO, 3.5% TiO2, 8.5% V2O5, total iron is 32.2%. The molten vanadium slag at a temperature of 1560°C is poured into an electric furnace for heat treatment of vanadium slag under the atmosphere, and at the same time, 1% of the mass of vanadium slag is added with sodium carbonate flux, and the temperature is kept for 20 minutes to ensure that the temperature distribution of the components is even. Then cool to 1240° C. at a cooling rate of 2° C. / min and hold the temperature for 30 minutes to obtain heat-treated molten vanadium slag containing solid-phase vanadium-iron spinel. After the heat treatment of the vanadium slag is completed, the obtained vanadium slag is poured onto a porous lime medium plate heated to 1000° C. for adsorption by means of drainage. The thickness of the porous lime medium plate is 100 mm. After the adsorption and sepa...

Embodiment 2

[0042] A vanadium-containing steel slag has been tested and its chemical composition is: 5.7% CaO, 21.4% SiO2, 1.1% Al2O3, 6.2% MgO, 8.6% MnO, 3.8% TiO2, 7.9% V2O5, and 29.8% total iron. The molten vanadium slag at a temperature of 1570° C. is poured into an electric furnace for heat treatment of vanadium slag in an atmospheric atmosphere, and at the same time, 0.8% boron trioxide flux by mass of the vanadium slag is added, and the temperature is kept for 20 minutes to ensure that the temperature distribution of the components is even. Then, it was cooled to 1230° C. at a cooling rate of 1.8° C. / min and held for 30 minutes to obtain heat-treated molten vanadium slag containing solid-phase vanadium-iron spinel. After the heat treatment of the vanadium slag is completed, the obtained vanadium slag is poured onto a normal temperature porous lime medium plate with a thickness of 50 mm for adsorption by means of drainage. Spinel fine vanadium slag (the grade of vanadium-iron spinel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com