Barium residue detoxifying method

A barium slag and raw material technology, which is applied in the field of solid waste disposal and cement materials, can solve the problems of high cost, failure to meet the requirements of detoxification, and difficulty in detoxification of barium slag, and achieves improved flexural strength and compressive strength, strong Absorption, pollution-resolving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

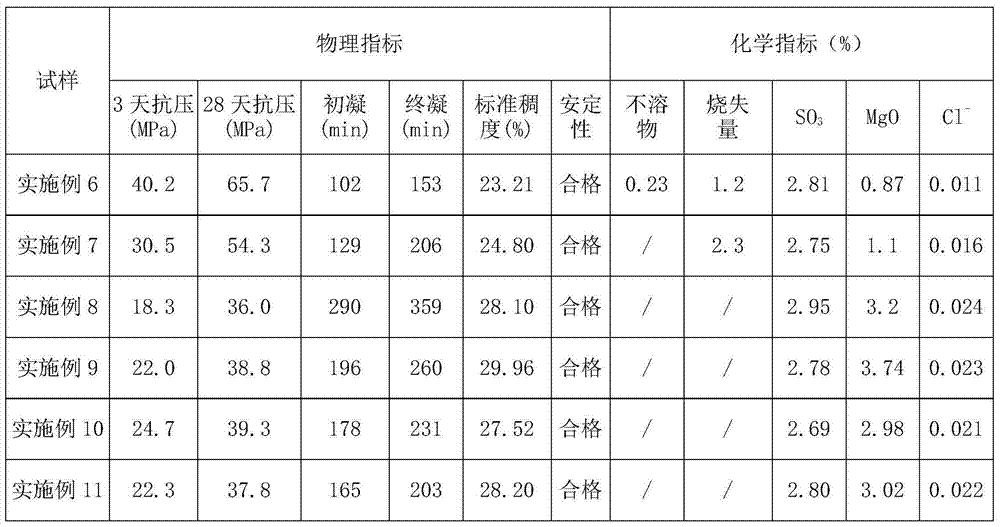

Examples

preparation example Construction

[0022] The method for preparing cement clinker adopted in the present invention is as follows: the above-mentioned raw materials are mixed in proportion through the batching system, and then dried and ground into a mill until the 45 micron sieve is less than 35%, or the 80 micron sieve is less than 20%, and the 200 micron sieve is less than 20%. Remainder is less than 2% to get raw meal powder (the sieve residue is mainly the crystalline SiO in the siliceous raw material 2 ); the raw meal powder enters the preheater and calciner for preheating and thermal decomposition reaction after being fully stirred evenly, and the apparent decomposition rate of the hot raw meal is controlled to be 90% to 95%, and then enters the cement kiln for calcination, and the calcination temperature is controlled At 1270°C-1370°C, the calcination time is 18-30 minutes, and the cement clinker can be obtained after cooling.

[0023] Further, the method for preparing Portland cement by using the above-...

Embodiment 1

[0024] Embodiment 1 (preparation of cement clinker):

[0025] Take 8 tons of limestone, 1.5 tons of clay, 0.45 tons of coal gangue, and 0.05 tons of barium slag, mix them evenly, dry them, grind them until the sieve of 45 microns is less than 35%, and obtain raw meal powder; Preheater (control preheater C1 temperature 310°C), calciner (control temperature 870°C) for preheating and thermal decomposition reaction, control the apparent decomposition rate of thermal raw material to 95%, and then enter the cement kiln for calcination, calcining The temperature is controlled at 1270°C, the calcining time is 30 minutes, and the cement clinker is obtained after cooling.

Embodiment 2

[0026] Embodiment 2 (preparation of cement clinker):

[0027] Take 4.5 tons of limestone, 4 tons of marl, 0.5 tons of loess, 0.5 tons of river mud, 0.3 tons of pyrite slag, and 0.2 tons of barium slag, mix them evenly, dry them, grind them to 80 microns and sieve them to less than 20% to get raw meal powder ; The raw meal powder enters the preheater (control the temperature of the preheater C1 at 300°C) and the decomposition furnace (control the temperature at 850°C) successively after being thoroughly stirred evenly, to carry out preheating and thermal decomposition reactions, and the apparent decomposition rate of the hot raw meal is controlled 93%, then enter the cement kiln for calcination, the calcination temperature is controlled at 1370°C, the calcination time is 18 minutes, and the cement clinker can be obtained after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com