Sulfate-erosion-resistant preservative for underground concrete structure

A technology for concrete structure and sulfate resistance, applied in the field of concrete admixture materials, can solve the problems of reduced concrete strength, unsatisfactory ettringite erosion, concrete cracking and damage, etc., and achieves low cost, excellent sulfate corrosion resistance, and manufacturing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

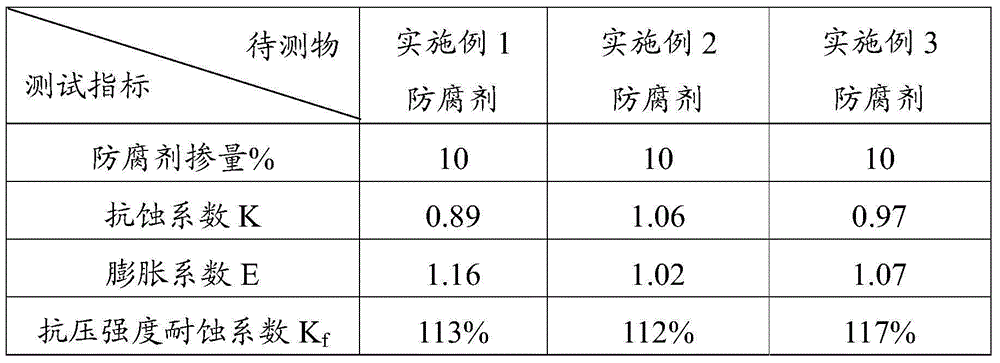

Embodiment 1

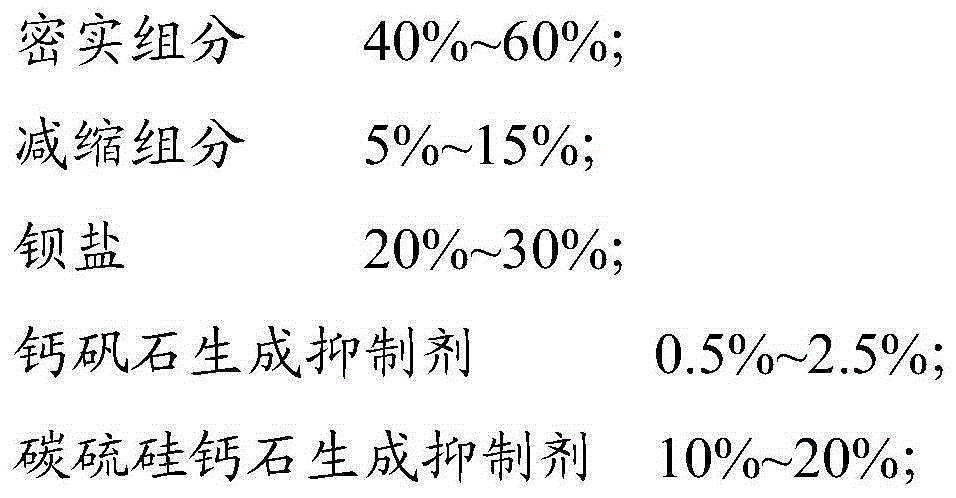

[0022] Weigh each component according to the following mass percentage: silica fume 5%, fly ash 48.9%, polydimethylsiloxane 3%, 2-methyl-2,4-pentanediol 5%, barium nitrate 13% , barium hydroxide 11%, nitrilo trimethylene phosphonic acid 0.1%, glycerin 8%, calcium phosphate 6%; and then mix the weighed components to obtain the preservative.

Embodiment 2

[0024] Weigh each component according to the following mass percentages: silica fume 8.5%, fly ash 38%, polydimethylsiloxane 3%, 2-methyl-2,4-pentanediol 7%, barium acetate 12% , barium hydroxide 14%, nitrilo trimethylene phosphonic acid 0.7%, hydroxyethylene diphosphonic acid 0.8%, dipropylene glycol 7%, calcium phosphate 9%; after that, mix the weighed components Get the preservative.

Embodiment 3

[0026] Weigh each component according to the following mass percentages: metakaolin 15%, fly ash 25%, polydimethylsiloxane 4%, 2-methyl-2,4-pentanediol 8%, barium nitrate 12% 16% barium acetate, 2% hydroxyethylidene diphosphonic acid, 5% glycerin, and 7% calcium phosphate; and then mix the weighed components to obtain the preservative.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com