Titanium spiral conveyor

A screw conveyor and screw shaft technology, applied in the field of screw conveyors, can solve the problems of low weld strength, low shear strength, poor corrosion resistance, etc., achieve safe and stable operation, meet anti-corrosion performance, and ensure corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

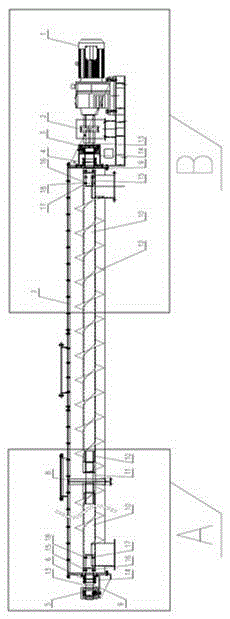

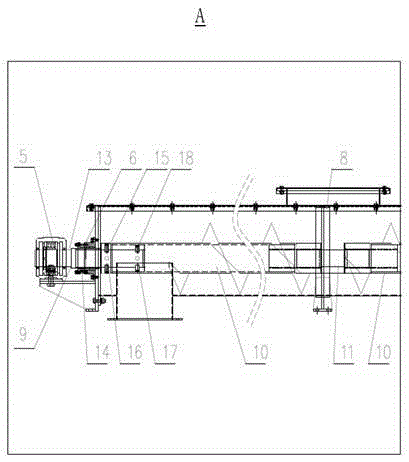

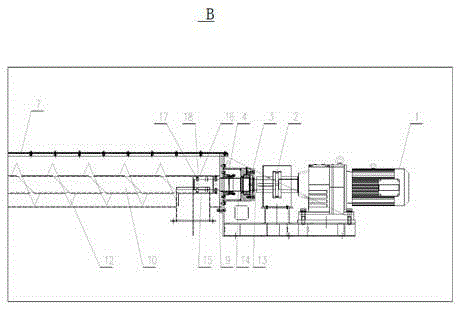

[0026] Such as Figure 1~Figure 5 As shown, the present invention includes a housing assembly composed of a housing 7 and a screw shaft support 8, and a motor speed reducer 1, a shaft coupling 2, a machine head bearing assembly 3 and a housing machine head are installed on the right side of the housing 7. The head assembly composed of the end seal assembly 4 is installed on the left side of the housing 7 with a tail assembly composed of the tail bearing assembly 5 and the tail end seal assembly 6 of the housing. The housing 7 is equipped with a shaft head 9, A screw shaft composed of a shaft tube 10, a shaft tube connector 11 and a helical blade 12. The shaft head 9 is inserted into the shaft tubes 10 at both ends of the screw shaft and welded as a whole. The shaft tube 10 in the middle of the screw shaft The shaft tube connector 11 is welded as a whole, and the shaft tube 10 and the spiral blade 12 are welded as a whole; the shaft head 9 includes a shaft head shaft 13, a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com