Composite build-up welding manufacturing method with corrosion resistant gasket welded to end part of flange

A technology for welding gaskets and manufacturing methods, which is applied in the field of composite surfacing welding manufacturing of anti-corrosion gaskets at the end of flanges, can solve problems such as poor anti-corrosion treatment effects, reduce welding deformation, improve welding efficiency, and meet The effect of anti-corrosion performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] As shown in the figure, the specific implementation method is as follows:

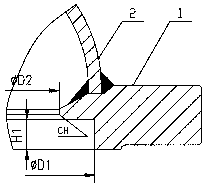

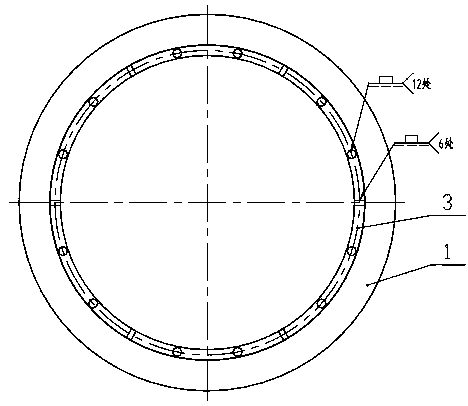

[0018] This embodiment is to carry out welding processing for the material of flange 1Q345R and the material of elliptical head 2Q345R, such as figure 1 As shown in , first weld the Q345R flange 1 welded with the Q345R elliptical head 2,

[0019] A composite overlay welding manufacturing method for welding anti-corrosion gaskets at flange ends, comprising the following steps:

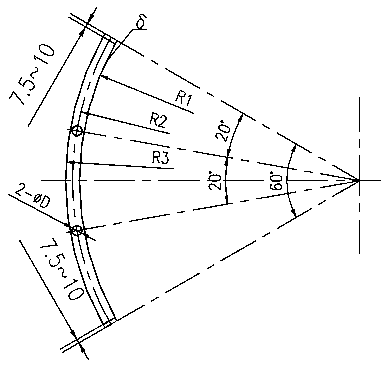

[0020] Step 1. Take the flange 1 to be welded with the gasket for rough machining, and process a flange with a diameter of D at the end of the flange where the gasket 3 needs to be installed. 1 Depth is H 1 A concave hole, a through hole through the flange is processed at the center of the concave hole, the diameter of the through hole is D 2 The closure of the via hole is H 2 According to the final product size of the gasket welded on the flange, a machining allowance of 3-5mm is reserved, and chamfering is performed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com