Water-based anti-corrosion coating for transformers and preparation method thereof

A technology of anti-corrosion coatings and transformers, applied in the field of coatings, can solve problems such as performance needs to be improved, and achieve the effects of excellent salt spray resistance, avoiding erosion, good hardness and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

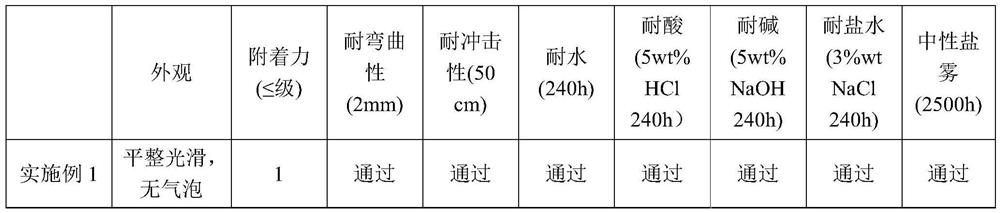

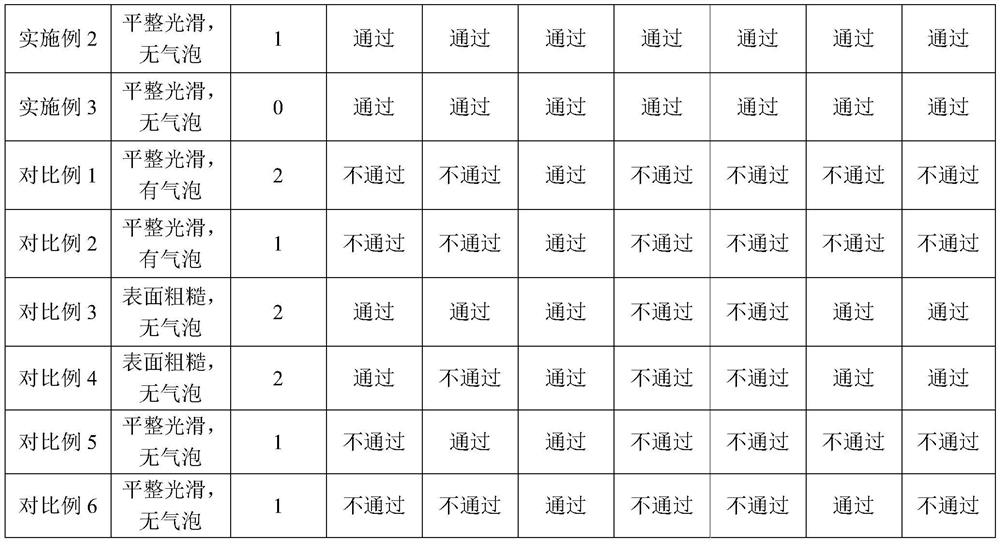

Examples

Embodiment 1

[0076] 1. Preparation of two-component water-based epoxy antirust primer:

[0077] Add 5 parts by weight of iron oxide red, 15 parts by weight of precipitated barium sulfate, 0.1 part by weight of dispersant BYK chemical BYK019, 0.1 part by weight of antifoaming agent BYK chemical BYK012 and 10 parts by weight of deionized water in the stirred tank. Fully stir for 20 minutes at a speed of 200 rpm, then transfer to a sand mill and grind to a fineness of 20 μm;

[0078] Transfer the above slurry to a stirring tank, add 35 parts by weight of water-based epoxy emulsion American Hexion Epikote827, 0.1 parts by weight of substrate wetting agent BYK333, 3 parts of graphene and 0.1 parts by weight of thickener French Gao Tai XS-71, stirred at 200r / min for 25 minutes, filtered, and the filtrate was component a of the two-component water-based epoxy antirust primer;

[0079] Two-component water-based epoxy anti-rust primer B component is epoxy curing agent American Hexion Epikure 829...

Embodiment 2

[0092] 1. Preparation of two-component water-based epoxy antirust primer:

[0093] Add 20 parts by weight of iron oxide red, 3 parts by weight of strontium chrome yellow, 30 parts by weight of precipitated barium sulfate, 1 part by weight of dispersant BYK2101, 0.3 parts by weight of defoamer BYK093 and 20 parts by weight into the stirring tank. Parts by weight of deionized water, fully stirred for 30 minutes at a speed of 2000 rpm, then transferred to a sand mill, and ground to a fineness of 30 μm;

[0094] Transfer the above slurry to a stirring tank, add 45 parts by weight of water-based epoxy emulsion American Hexion Epikote828LVEL, 0.3 parts by weight of substrate wetting agent BYK346, 8 parts of graphene and 0.3 parts by weight of sea name Stechem Polyurethane thickener WT-102, stirred at 2000r / min for 35 minutes, filtered, and the filtrate is component a of the two-component water-based epoxy antirust primer;

[0095] Two-component water-based epoxy anti-rust primer b ...

Embodiment 3

[0108] 1. Preparation of two-component water-based epoxy antirust primer:

[0109] Add 12 parts by weight of iron oxide red, 2 parts by weight of strontium chrome yellow, 25 parts by weight of precipitated barium sulfate, 0.5 parts by weight of dispersant BYK2101, 0.2 parts by weight of defoamer BYK093 and 15 parts by weight into the stirring tank Parts by weight of deionized water, fully stirred for 25 minutes at a speed of 1100 rpm, then transferred to a sand mill, and ground to a fineness of 25 μm;

[0110] Transfer the above slurry to a stirring tank, add 40 parts by weight of water-based epoxy emulsion American Hexion Epikote828LVEL, 0.2 parts by weight of substrate wetting agent BYK346, 5 parts of graphene and 0.2 parts by weight of sea name Stechem WT-102 polyurethane thickener, stirred at 1100r / min for 30 minutes, filtered, and the filtrate was component a of the two-component water-based epoxy antirust primer;

[0111] Two-component water-based epoxy anti-rust primer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com