Portable direct-reading type power-free hydrogen-sulfide gas detector and preparation of indicating matter

A gas detector, direct-reading technology, applied in material analysis by observing the influence of chemical indicators, analysis by chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problem of high cost and time-consuming. , unfavorable for all-day, continuous, multi-point monitoring work, etc., to achieve the effect of good accuracy and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

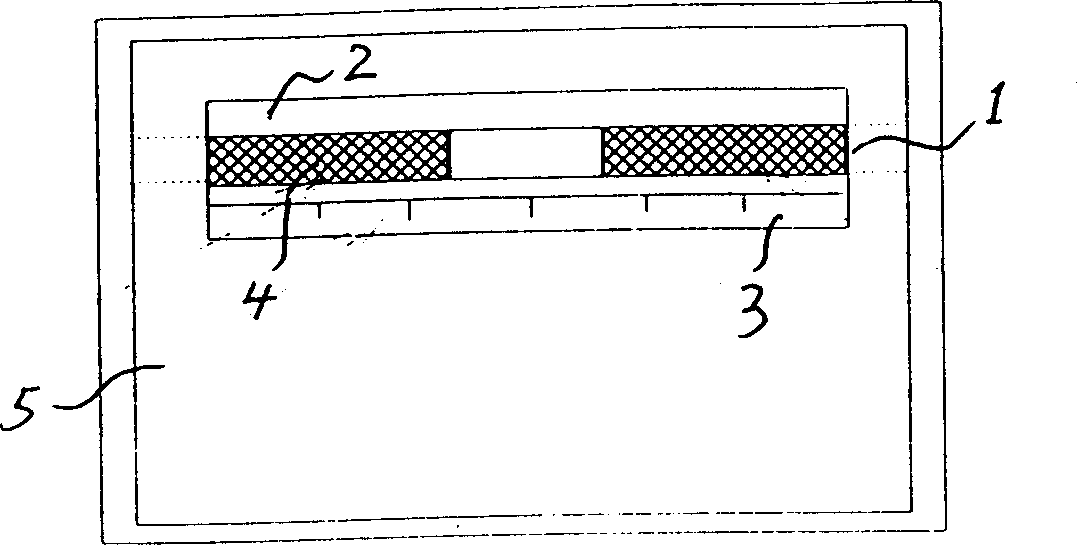

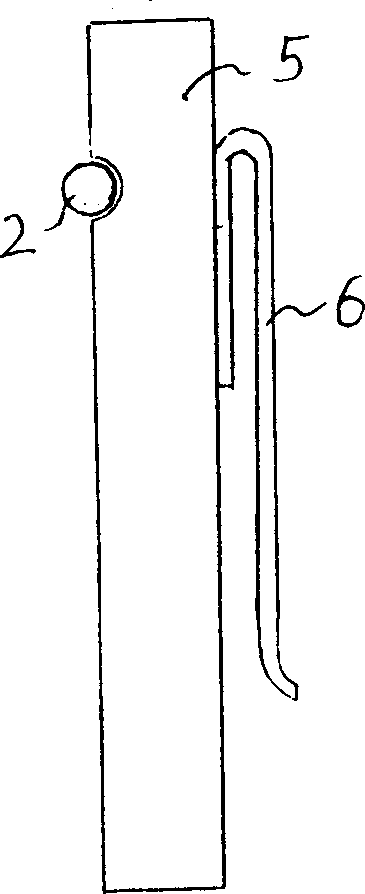

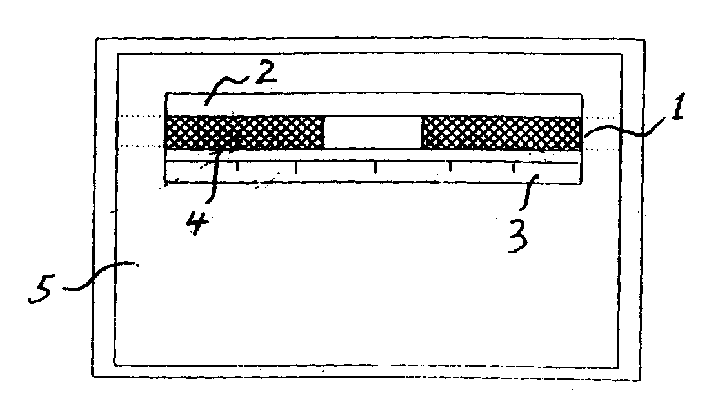

Image

Examples

Embodiment 1

[0038] Pure α-Al 2 o 3 Grind the type ceramics to 80-120 mesh, sieve, burn in a muffle furnace at 600°C for 2 hours, cool down, and bottle for use. The main agent composed of lead nitrate and lead acetate mixed in an equimolar proportion is weighed according to 5% of the total weight of the mixture. Weigh the interface agent barium chloride by 0.5% of the total weight of the mixture. Mix the above-mentioned main agent and interface agent, and add a small amount of distilled water to dissolve it, then pour it into pure α-Al which weighs 94.5% of the total weight of the mixture 2 o 3 Type ceramic powder, stir well, dry, put into airtight container for later use.

Embodiment 2

[0040] Weigh the main agent composed of lead acetate and silver nitrate in an equimolar ratio by 8% of the total weight of the mixture, weigh the interface agent barium acetate by 0.5% of the total weight of the mixture, and weigh pure α- al 2 o 3 type ceramic powder. The preparation method and steps are the same as above.

Embodiment 3

[0042] Weigh the main agent lead acetate by 3% of the total weight of the mixture, weigh the interface agent barium chloride by 0.8% of the total weight of the mixture, and weigh pure α-Al by 96.2% of the total weight of the mixture 2 o 3 type ceramic powder. The preparation method and steps are the same as above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com