Preparation method of submicron-grade barium sulfate

A sub-micron, nano-barium sulfate technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of complex preparation process, poor dispersion, difficult particle size control of sub-micron barium sulfate products, etc., and achieve the effect of less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

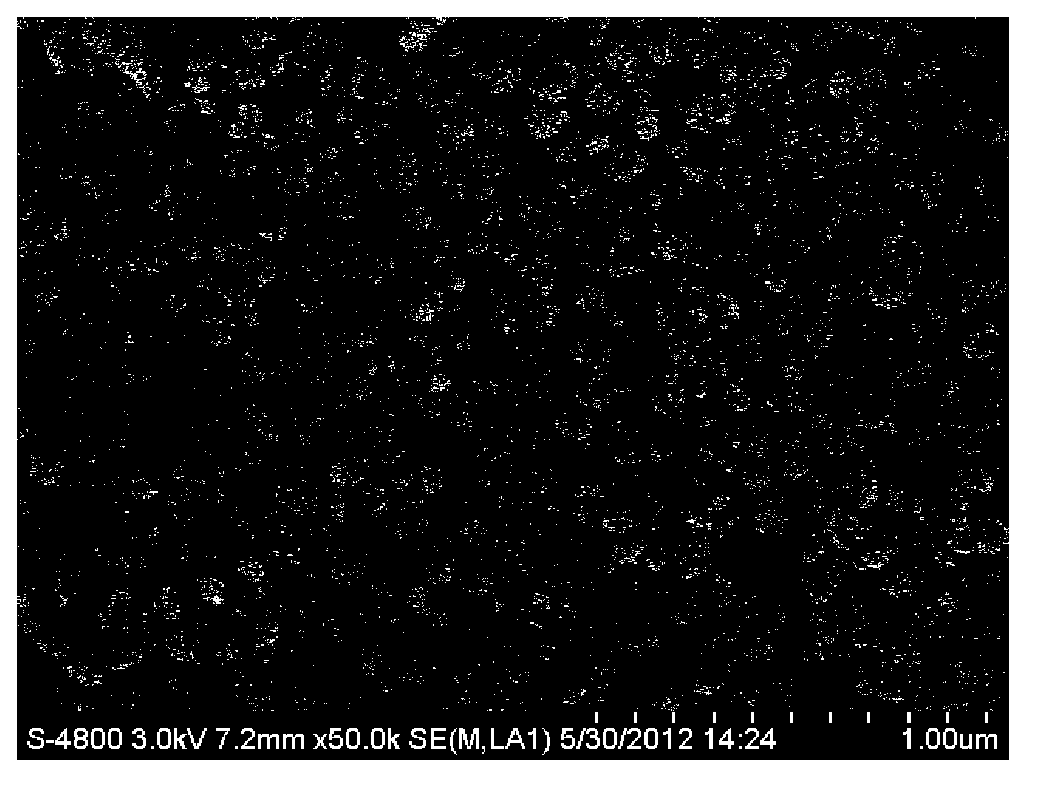

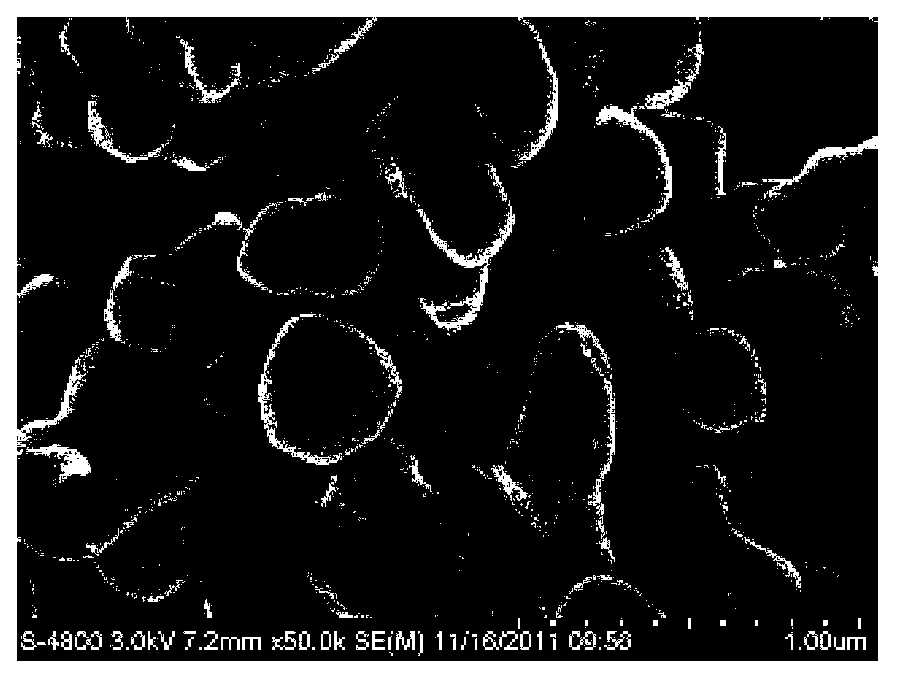

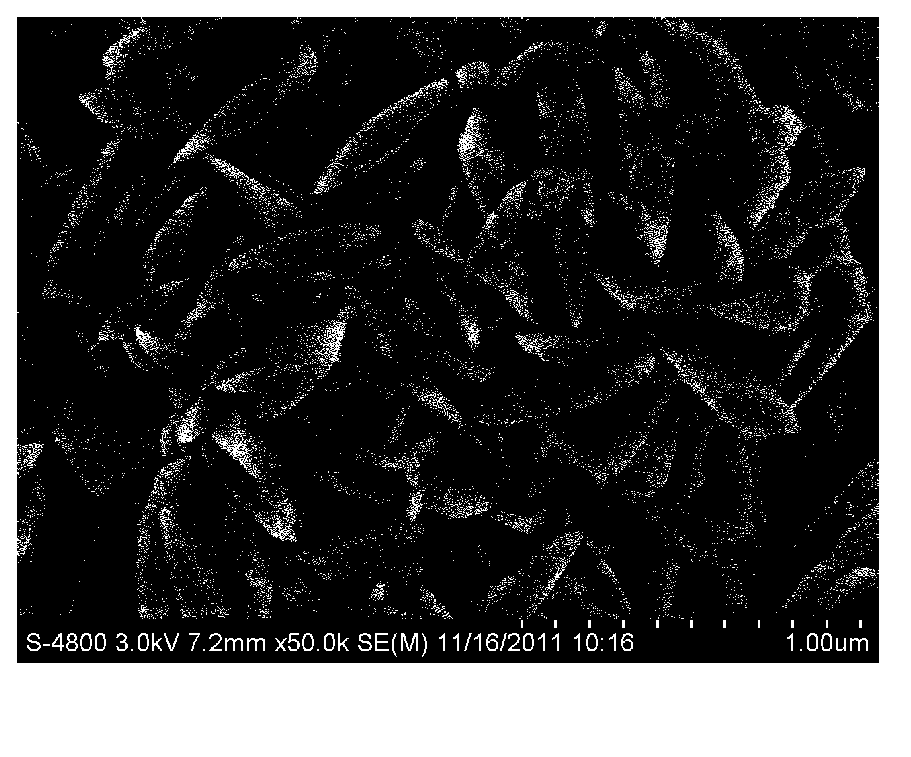

Image

Examples

preparation example Construction

[0027] A kind of preparation method of submicron order barium sulfate of the present invention, it comprises following specific processing steps:

[0028] a Seed crystal preparation

[0029] Prepare barium chloride and anhydrous sodium sulfate into solutions of 0.01-2.0 mol / L respectively, add them to barium chloride solution storage tank and sodium sulfate solution storage tank respectively, and feed nitrogen gas into the two storage tanks respectively, so that The barium chloride and sodium sulfate solutions react through the microreactor at a certain flow rate, and the two salt solutions collide and mix in an instant to obtain the product nano-barium sulfate, and its particle size is about 25-40nm.

[0030] b Preparation of the primary product of submicron barium sulfate

[0031] Nano-barium sulfate is used as the seed crystal, and the amount added is 0.1%-20.0% of the final submicron barium sulfate product amount, and the nano-barium sulfate seed crystal is ultrasonically...

Embodiment 1

[0036] a, the preparation of crystal seed: barium chloride and anhydrous sodium sulfate are respectively configured into the solution of 0.5mol / L, two kinds of solutions that are configured are poured in barium chloride solution storage tank and sodium sulfate solution storage tank respectively, And feed N into the two storage tanks 2 , the two solutions are adjusted to pass through the counterflow microreactor at a flow rate of 10 L / h, and the reaction temperature is controlled to be about 25° C. to obtain 25-40 nm seed barium sulfate.

[0037] b. Preparation of submicron barium sulfate: take nanometer barium sulfate seeds and disperse them by ultrasonic. Barium chloride and sodium sulfate were respectively configured into 0.7mol / L solutions, and 200ml of water was poured into a four-neck flask, and 5% was taken according to the mass ratio (the mass ratio of the final submicron barium sulfate product, the same below ) dispersed barium sulfate seeds, start stirring, and contr...

Embodiment 2

[0040] a, the preparation of crystal seed: barium chloride and anhydrous sodium sulfate are respectively configured into the solution of 0.5mol / L, two kinds of solutions that are configured are poured in barium chloride solution storage tank and sodium sulfate solution storage tank respectively, And feed N2 into the two storage tanks, adjust the two solutions to pass through the collision flow microreactor at a flow rate of 10L / h, control the reaction temperature at about 25°C, and obtain nano-barium sulfate of 25~40nm;

[0041] b. Preparation of submicron barium sulfate: take nano-barium sulfate seeds, disperse them by ultrasonic waves, prepare barium chloride and sodium sulfate into 0.5mol / L solutions respectively, and pour 200ml of water into a four-necked flask , measure the dispersed nano-barium sulfate seed crystals, start stirring, and control the rotation speed to 90r / min; keep the temperature of the solution in the four-necked bottle constant at 40°C, and add 100mL of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com