Normal temperature barium salt modified phosphorizing liquid capable of avoiding water wash after phosphorized

A technology of phosphating solution and barium salt, which is applied in the coating process of metal materials, etc., can solve the problems of unacceptable quality of phosphating film, short life of phosphating solution, poor phosphating quality, etc., and achieve excellent corrosion resistance, sediment The effect of less and material consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

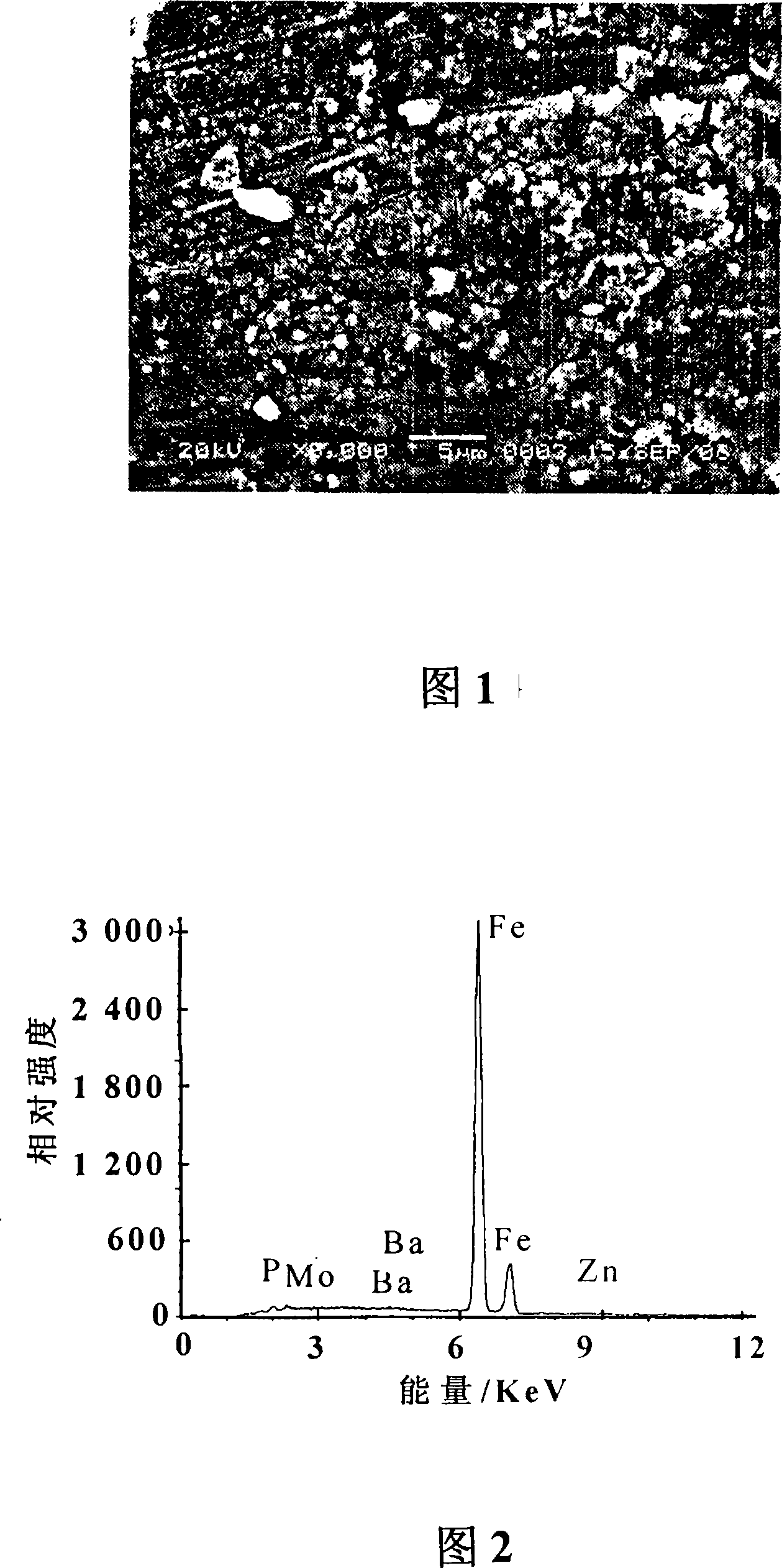

Image

Examples

Embodiment 1

[0068] Phosphating solution formula: zinc oxide [ZnO]: 5.5g L -1 ; Industrial phosphoric acid [H 3 PO 4 ]: 23.5g L -1 ; Ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 4H 2 O]: 2.0g L -1 ; Barium nitrate [Ba(NO 3 )2]: 3.50g L -1 ; Nickel nitrate [Ni(NO 3 ) 2 ·6H 2 O]: 2.50g·L -1 ; Phytic acid (C 6 h 18 o 24 P 6 ): 1.5g L -1 ; With ammonia (NH 3 ·H 2 O) Adjust the pH to 2.9.

[0069] Phosphating conditions and results: dipping and phosphating at 10°C for 600s, and then drying naturally for 3 hours to obtain a continuous and uniform colored phosphating film without quality defects, and then tested for corrosion resistance time of 85s; adhesion reached level 1.

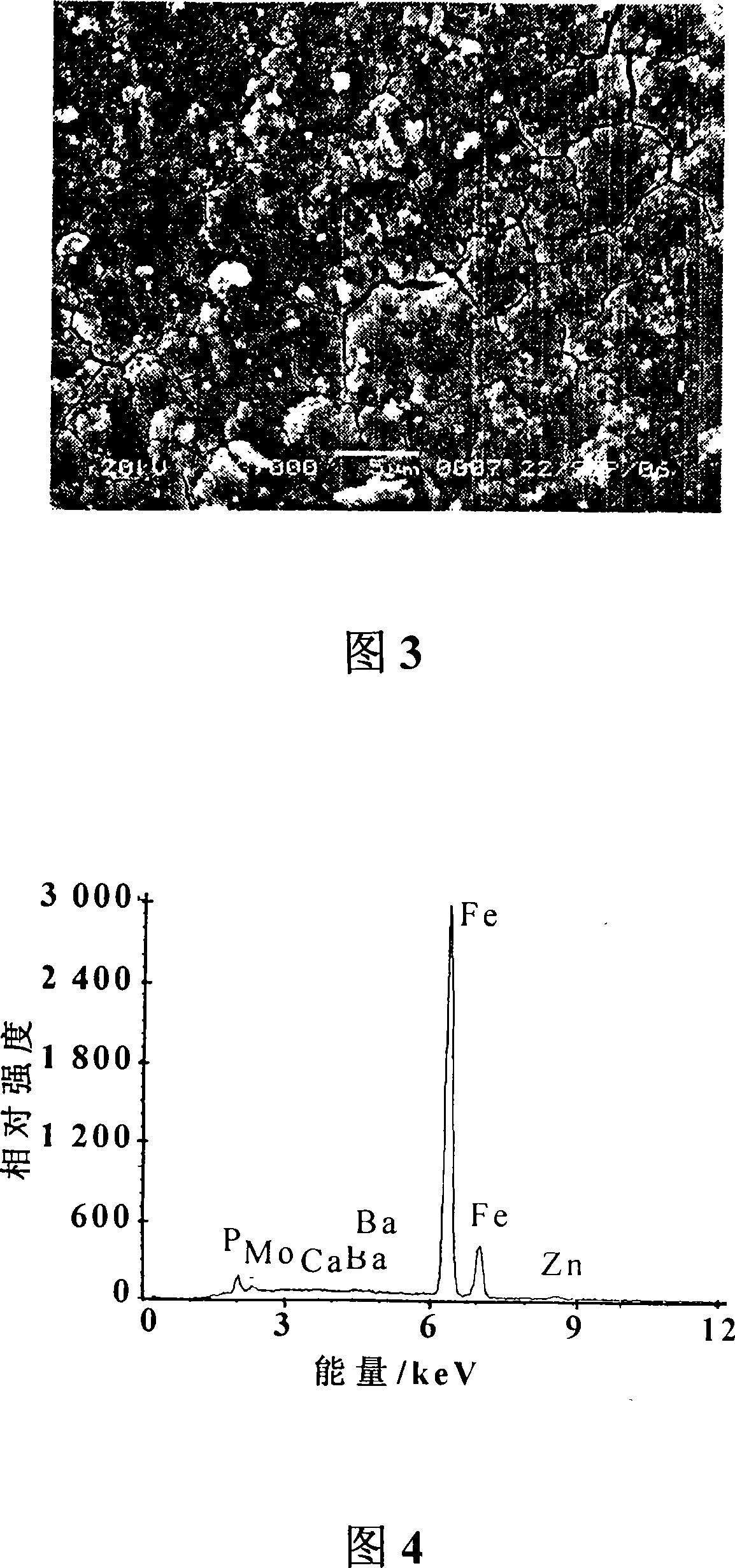

Embodiment 2

[0071] Phosphating solution formula: zinc oxide [ZnO]: 3.5g L -1 ; Industrial phosphoric acid [H 3 PO 4 ]: 23.5g L -1 ; Calcium nitrate [Ca(NO 3 ) 2 4H 2 O]: 3.5g L -1 ; Nickel nitrate [Ni(NO 3 ) 2·6H 2 O]: 2.50g·L -1 ; Ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 4H 2 O]: 2.30g·L -1 ; Barium nitrate [Ba(NO 3 ) 2 ]: 0.60g·L -1 ; Phytic acid (C 6 h 18 o 24 P 6 ): 1.0g·L -1 ; With ammonia (NH 3 ·H 2 O) Adjust the pH to 2.6.

[0072] Phosphating conditions and results: dipping and phosphating at 30°C for 400s, and then drying naturally for 3 hours to obtain a continuous and uniform colored phosphating film without quality defects, and then tested for corrosion resistance time of 135s; adhesion reached level 1.

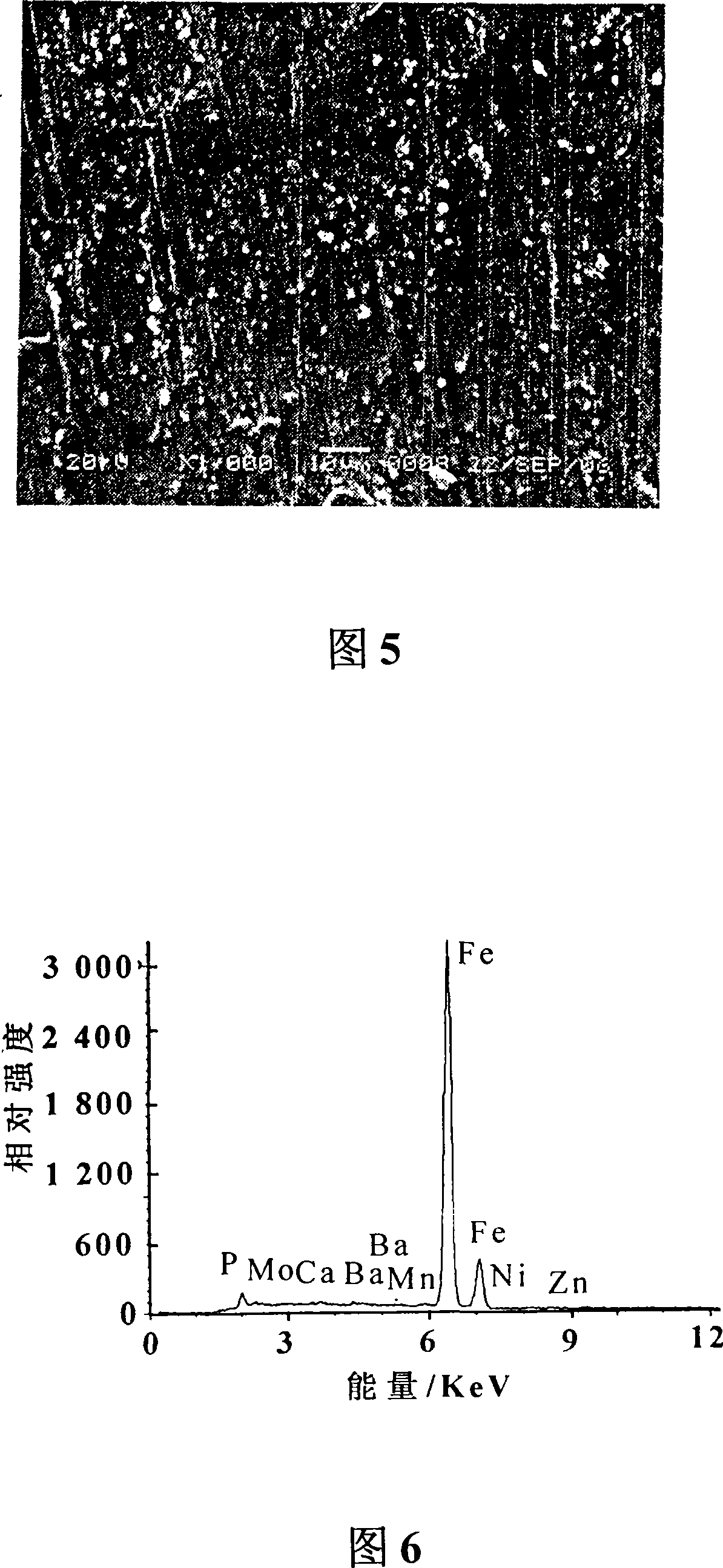

Embodiment 3

[0074] Phosphating solution formula: zinc oxide [ZnO]: 3.0g L -1 ; Calcium nitrate [Ca(NO 3 ) 2 4H 2 O]: 2.0g; industrial phosphoric acid [H 3 PO 4 ]: 21.5g L -1 ; Manganese dihydrogen phosphate [Mn(H 2 PO 4 ) 2 ·H 2 O]: 1.5g L -1 ; Ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 4H 2 O]: 0.30g·L -1 ; Barium nitrate [Ba(NO 3 ) 2 ]: 1.30g·L -1 ; Phytic acid (C 6 h 18 o 24 P 6 ): 1.2g L -1 ; With ammonia (NH 3 ·H 2 O) Adjust the pH to 2.3.

[0075] Phosphating conditions and results: Spray phosphating at 20°C for 60s, and dry naturally for 3 hours to obtain a continuous and uniform color phosphating film without quality defects, and then check that the corrosion resistance time is 65s; the adhesion reaches level 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com