Test method for XCT nondestructive detection of sulfate erosion damages of concrete material

A technology of non-destructive testing and test methods, applied in the direction of analyzing materials, using radiation for material analysis, using wave/particle radiation for material analysis, etc., to achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

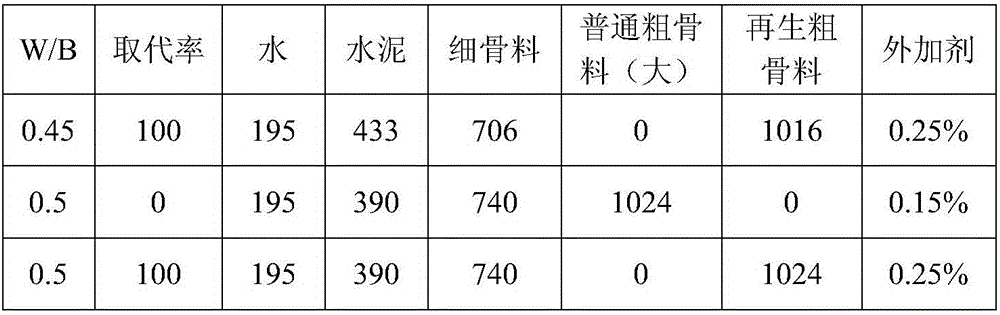

[0024] The present invention takes recycled concrete as an example, and the specific mix ratio is shown in the following table.

[0025]

[0026] Stir according to the above mixing ratio, and form a 40mm×40mm×160mm concrete specimen. After forming, it will be cured with the mold for 24 hours. After the mold is removed, it will be placed in a standard curing room (temperature 20±1°C, RH above 95%) for 56 days; After drying in a drying oven at 60°C for 48 hours, the first round of XCT scanning was performed, recorded as the information that the corrosion age was 0 days, and placed in a dry-wet cycle simulation test chamber. The dry-wet cycle system is set as follows: the cycle is 3 days, soaked in sulfate solution for 21 hours, air-dried at room temperature for 3 hours, dried at 60°C for 45 hours, cooled at room temperature for 3 hours, and the dry-wet cycle is one cycle. After the number of dry and wet cycles was 10, 30, 60 and 100, the specimens were taken out, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com