Sulfate-corrosion-resistant concrete and preparation method thereof

A sulfate and concrete resistance technology, applied in the field of concrete, can solve the problems of reducing concrete strength and viscosity, affecting concrete durability, cracking, spalling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

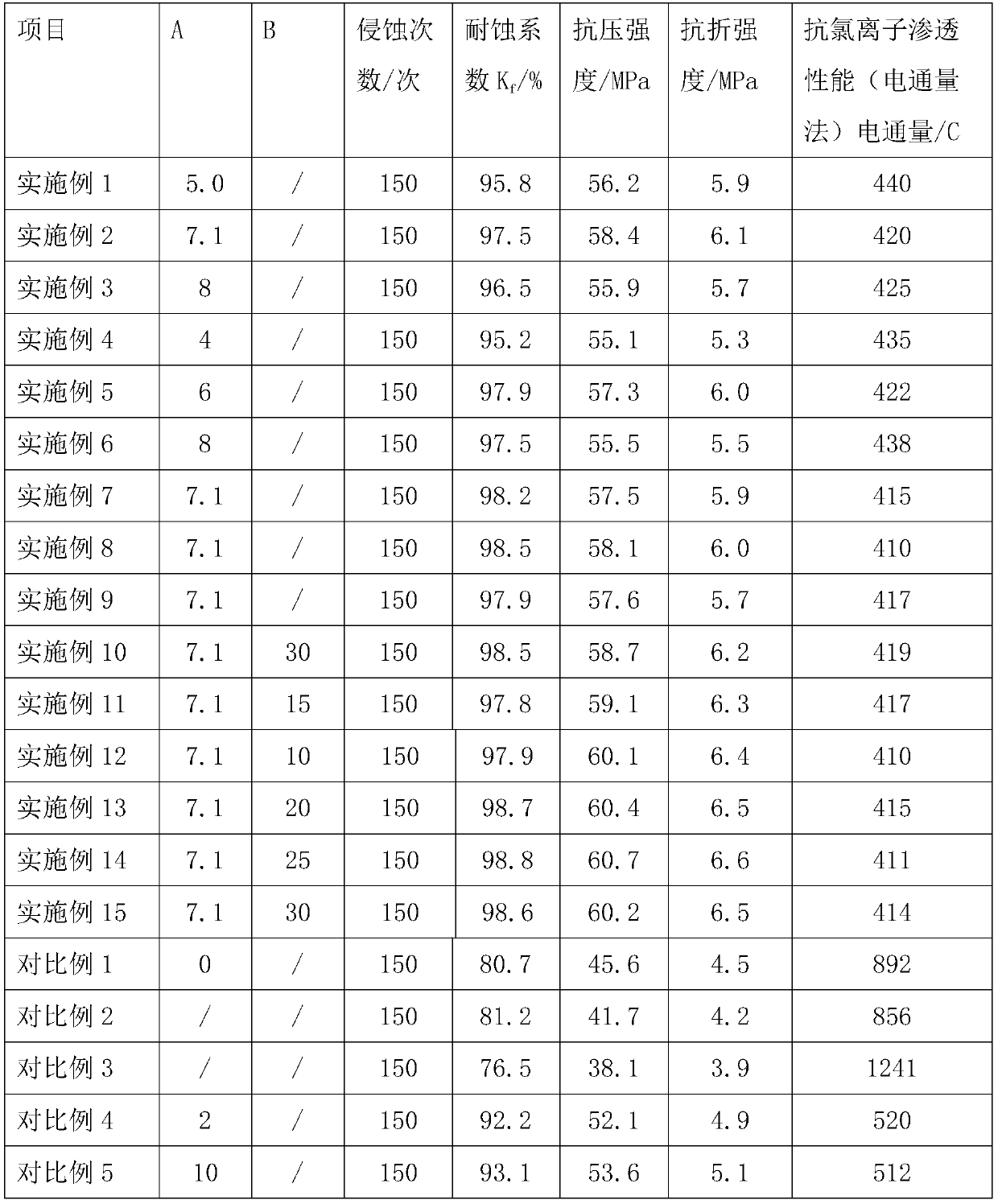

Examples

Embodiment 1

[0046] A sulfate-resistant concrete, comprising 240 parts by weight of cement, 150 parts of water, 70 parts of fly ash, 80 parts of mineral powder, 660 parts of natural sand, 1200 parts of crushed stone, 50 parts of epoxy resin, silicon 10 parts of ash, 7 parts of admixture, 1 part of barium hydroxide, 0.2 parts of sodium citrate, 2 parts of steel fiber;

[0047] Among them, the admixture contains the following components: polycarboxylic acid, silicone oil and rosin soap, the weight ratio of polycarboxylic acid, silicone oil and rosin soap is 1.0:1.2:1.8, that is, 1.75 parts of polycarboxylic acid, 2.1 parts of silicone oil , 3.15 parts of rosin soap.

[0048] The preparation method of above-mentioned sulfate-resistant concrete is as follows:

[0049] Put the above-mentioned other components except water into a mixer and mix them, then add water into the mixer, and stir for 10 minutes to prepare the above-mentioned sulfate-resistant concrete.

Embodiment 2

[0051] A sulfate-resistant concrete, comprising 300 parts by weight of cement, 170 parts of water, 80 parts of fly ash, 100 parts of mineral powder, 710 parts of natural sand, 1350 parts of crushed stone, 60 parts of epoxy resin, silicon 15 parts of ash, 8 parts of admixture, 2.5 parts of barium hydroxide, 0.35 parts of sodium citrate, 6 parts of steel fiber;

[0052] Wherein, the admixture contains the following components: polycarboxylic acid, silicone oil and rosin soap, the weight ratio of polycarboxylic acid, silicone oil and rosin soap is 1.2:1.2:2.0, that is, 2.18 parts of polycarboxylic acid, 2.18 parts of silicone oil , 3.64 parts of rosin soap.

[0053] The preparation method of above-mentioned sulfate-resistant concrete is as follows:

[0054] Put the above-mentioned other components except water into a mixer and mix them, then add water into the mixer, and stir for 15 minutes to prepare the above-mentioned sulfate-resistant concrete.

Embodiment 3

[0056] A sulfate-resistant concrete, comprising 360 parts by weight of cement, 190 parts of water, 90 parts of fly ash, 120 parts of mineral powder, 760 parts of natural sand, 1500 parts of crushed stone, 70 parts of epoxy resin, silicon 20 parts of ash, 9 parts of admixture, 4 parts of barium hydroxide, 0.5 parts of sodium citrate, 10 parts of steel fiber;

[0057] Among them, the admixture contains the following components: polycarboxylic acid, silicone oil and rosin soap, the weight ratio of polycarboxylic acid, silicone oil and rosin soap is 1.4:1.2:2.2, that is, 2.625 parts of polycarboxylic acid, 2.25 parts of silicone oil , 4.125 parts of rosin soap.

[0058] The preparation method of above-mentioned sulfate-resistant concrete is as follows:

[0059] Put the above-mentioned other components except water into a mixer and mix them, then add water into the mixer, and stir for 20 minutes to prepare the above-mentioned sulfate-resistant concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com