Cement concrete modifying agent resistant to sulfate erosion and preparation method thereof

A technology of cement concrete and sulfate resistance, which is applied in the field of building materials to achieve the effects of improving the performance of sulfate corrosion resistance, significant filling effect, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

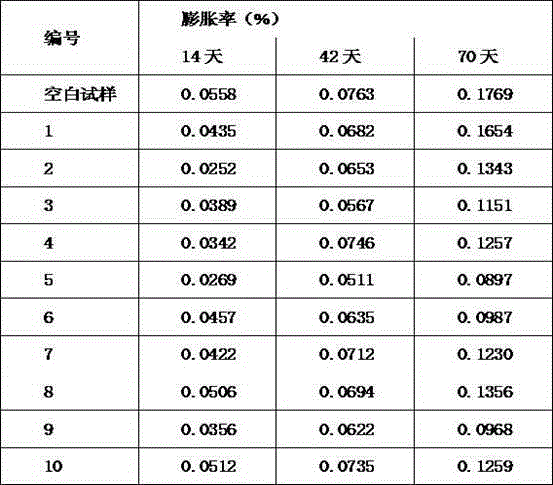

[0024] The invention discloses a sulfate corrosion-resistant modifier for cement concrete, which is prepared from metakaolin, calcined hydrotalcite, fly ash and limestone powder. Metakaolin is calcined at 700°C for 4 hours and then cooled and pulverized. Calcined hydrotalcite is calcined at 500°C for 4 hours and then cooled. The ratio of modifiers used to modify the sulfate attack resistance of cement concrete is shown in Table 1.

[0025] Table 1 Proportion of cement concrete anti-sulfate attack modifier

[0026]

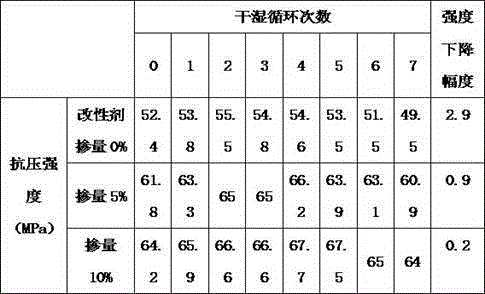

[0027] With reference to the provisions of GB / T749-2008 "Test Method for Resistance to Sulfate Erosion of Cement", the present invention uses cement concrete sulfate erosion resistance modifier combined with cement and dihydrate gypsum to prepare cement mortar test blocks, and the experimental water-cement ratio is 0.36 , The size of the test block is 25×25×280 mm. By adding a certain amount of dihydrate gypsum to the cement, the SO in the cement 3 The conten...

Embodiment 2

[0033] The invention discloses a sulfate corrosion-resistant modifier for cement concrete, which is prepared from metakaolin, calcined hydrotalcite, fly ash and limestone powder. Metakaolin is calcined at 700°C for 4 hours and then cooled and pulverized. Calcined hydrotalcite is calcined at 500°C for 4 hours and then cooled. According to numbers 3, 4, and 5 in Table 1, prepare cement concrete sulfate corrosion modifiers, and add them to cement concrete in proportions of 0, 5% and 10%, respectively. The cement concrete proportioning ratio is shown in Table 3.

[0034] Table 3 concrete mix ratio

[0035]

[0036]According to the method of GB / T50080-2002 "General Concrete Mixture Performance Test Method Standard", the slump of the concrete mixture was tested, and the test results are shown in Table 4.

[0037] Table 4 Concrete slump

[0038]

[0039] The test results show that the performance of the concrete mixed with the anti-sulphate corrosion modifier is not significa...

Embodiment 3

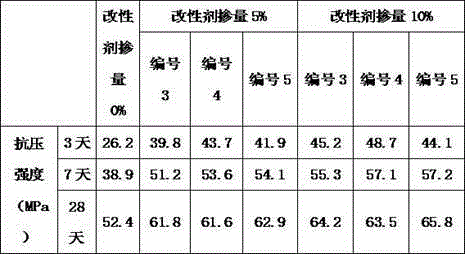

[0041] The invention discloses a sulfate corrosion-resistant modifier for cement concrete, which is prepared from metakaolin, calcined hydrotalcite, fly ash and limestone powder. Metakaolin is calcined at 700°C for 4 hours and then cooled and pulverized. Calcined hydrotalcite is calcined at 500°C for 4 hours and then cooled. According to No. 3, 4, and 5 in Table 1, prepare cement concrete sulfate corrosion modifiers, and add them to cement concrete in proportions of 5% and 10%, respectively. The proportion of cement concrete is shown in Table 3.

[0042] According to the method of GB / T50081-2002 "Standard for Test Methods of Mechanical Properties of Ordinary Concrete", the 3-day, 7-day and 28-day compressive strength of concrete was tested, and the test results are shown in Table 5.

[0043] Table 5 Concrete compressive strength test results

[0044]

[0045] The test results show that the compressive strength of the concrete mixed with the anti-sulfate corrosion modifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com