Tunnel construction structure for draining and desilting

A technology for tunneling and sedimentation, applied in tunnels, drainage, safety devices, etc., can solve the problems of large negative impact on environmental protection, long construction period and high investment, and achieve the effects of reduced project investment, short construction period and quick effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

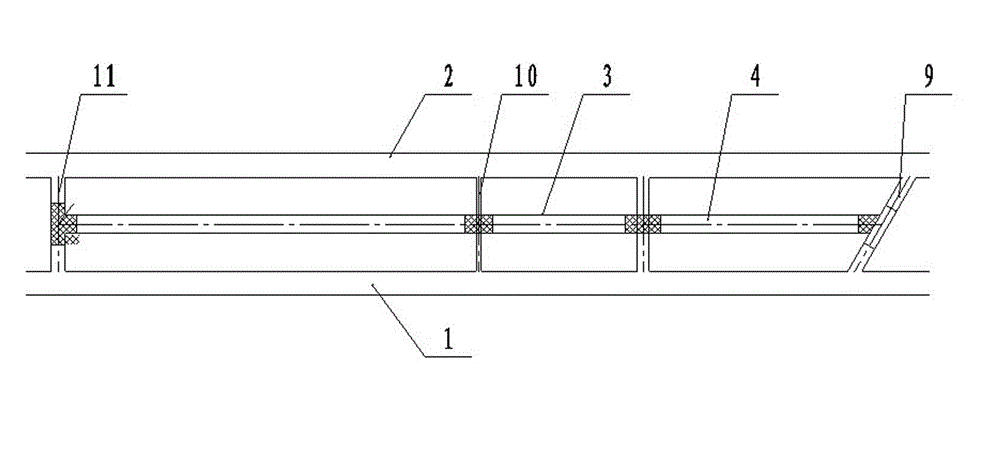

[0025] Project Overview

[0026] Baojiashan Tunnel: It is a controlled project from Xiao (he) to (An)kang section of Baomao Expressway, with a total length of 11.2 kilometers. The entrance of the tunnel is located at Tongmugou, Xunyang County, and the exit is located at Chaijia River in Ankang City, crossing the South Qinling Mountains. The two peaks of the mountain range, Qingshan and Yuhuangshan, the tunnel crosses 37 faults, 3 large fold belts, and 25 gushing sections. The surrounding rock of the tunnel is mainly schist and phyllite, and layered limestone is distributed in the middle section of the tunnel. During the construction phase, shaft No. 1 and inclined shaft No. 3 need to be used to undertake the construction tasks of 4.1 main tunnel; however, since shaft No. 1 and inclined shaft No. 3 of the Baojiashan Tunnel are located in the limestone section of the middle section, the tunnel has been caused by surface rainfall since the start of construction There have been seve...

example 2

[0035] Project Overview

[0036] The Mixiliang Tunnel is a key control project of the Baotou-Maoming Expressway (G65) Shaanxi Jingankang-Ziyang section of the national expressway network. It is a curved tunnel with left and right lines. The tunnel is 7928 meters in length and is an extra-long two-lane expressway. Highway tunnel. After the right tunnel was excavated to YK242+575, the water inflow of the cavern suddenly increased and a landslide was formed. The water gushing section was affected by the F242-1 fault on the north side of the regional fault F4-6. The surrounding rock fissures were relatively developed, and the rock mass Relatively broken, the fracture structure forms a permeable water channel. The measured water inflow at the tunnel face of the fault zone is 16,946 meters 3 / day. In order to complete the excavation of the main tunnel and serve the operational needs, after repeated field studies, it was decided to deal with the construction structure according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com