High buffer insulating composite paperboard

A technology of composite board and paperboard, which is applied in the field of high-buffering and heat-insulating composite paperboard, can solve the problems that cannot meet the requirements, and the impact resistance of honeycomb paperboard has no function, so as to achieve good heat insulation and moisture-proof effect, reduce impact resistance and improve toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

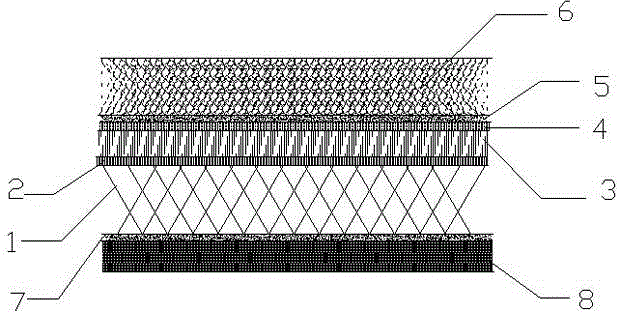

[0023] A high-buffer heat-insulating composite paperboard, comprising a honeycomb paperboard layer 1, a barrier film I2 is pasted on the honeycomb paperboard layer 1, a fiber fabric layer 3 is provided on the barrier film I2, a barrier film II4 is provided on the fiber fabric layer 3, and the barrier film II4 is coated with inorganic fiber coating I5, and the inorganic fiber coating I5 is covered with polylactic acid-aliphatic polyester composite foam board 6; the honeycomb paperboard layer 1 is coated with inorganic fiber coating II7, and the bottom of the inorganic fiber coating II7 Covered with polylactic acid-elastomer composite sheet 8 . The fiber fabric layer 3 is filled with nanocomposite suspension, which can improve the impact resistance of the composite board 8 .

[0024] The fiber fabric layer 3 is a double-layer structure woven with polyester fibers, and the mesh number of the holes is 400 mesh. The nanocomposite suspension comprises a dispersion medium and nanome...

Embodiment 2

[0034] A high-buffer heat-insulating composite paperboard, comprising a honeycomb paperboard layer 1, a barrier film I2 is pasted on the honeycomb paperboard layer 1, a fiber fabric layer 3 is provided on the barrier film I2, a barrier film II4 is provided on the fiber fabric layer 3, and the barrier film II4 is coated with inorganic fiber coating I5, and the inorganic fiber coating I5 is covered with polylactic acid-aliphatic polyester composite foam board 6; the honeycomb paperboard layer 1 is coated with inorganic fiber coating II7, and the bottom of the inorganic fiber coating II7 Covered with polylactic acid-elastomer composite sheet 8 . The fiber fabric layer 3 is filled with nanocomposite suspension, which can improve the impact resistance of the composite board 8 .

[0035] The fiber fabric layer 3 is a single-layer structure woven with viscose fibers, and the mesh number of the holes is 400 mesh. The nanocomposite suspension comprises a dispersion medium and nanomete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com