High anti-impact waterproof and dampproof composite board

A high-impact, composite board technology, applied in the direction of synthetic resin layered products, paper/cardboard layered products, layered products, etc., can solve the problems of unsuitable light packaging, the impact of waterproof and moisture resistance, and poor impact resistance of boards, etc. problems, to achieve good environmental characteristics, low cost, and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

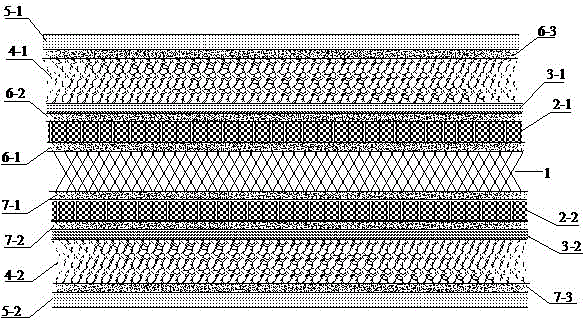

[0028] refer to figure 1 , propose an embodiment of a high-impact waterproof and moisture-proof composite board of the present invention:

[0029] A high-impact waterproof and moisture-proof composite board is composed of multi-layer materials, including an upper structure, a lower structure and a honeycomb paperboard layer 1 arranged between the upper structure and the lower structure. The upper layer structure includes, from top to bottom, the upper wear-resistant plastic film layer 5-1, the upper inorganic fiber coating III6-3, the upper cardboard foam layer 4-1, the upper waterproof film layer 3-1, and the upper inorganic fiber coating II6 -2. The upper high-impact fiber layer 2-1 and the upper inorganic fiber coating I6-1, the lower layer structure from bottom to top includes the lower wear-resistant plastic fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com