Amino-acid-type surfactant self-thickening composition

A technology of composition and thickening agent, which is applied in skin care preparations, cosmetics, hair care and other directions, can solve the problems of dirty cleaning, stickiness, easy discoloration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

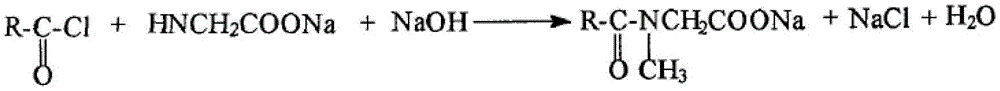

Method used

Image

Examples

Embodiment 1

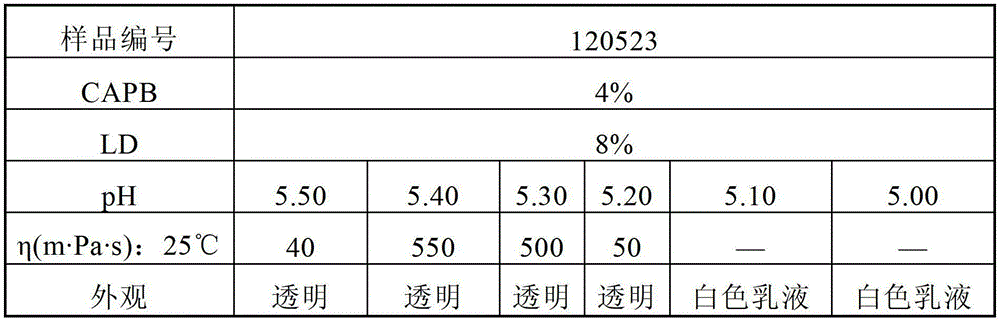

[0036] Example 1: Thickening experiment when the ratio of CAPB and LD is 4%:8%

[0037] 1. Experimental materials

[0038] Sodium lauroyl sarcosinate, purchased from Clariant Company, batch number is CNM1004235 (trade name is MEDIALAN LD), also can be referred to as LD in this article; Cocamidopropyl betaine, purchased from Degussa Company, batch number is BE02201043 (trade name TEGO BETAIN F50), which may also be referred to herein as CAPB.

[0039] 2. Experimental equipment:

[0040] Viscometer: Brookfield DV-2Pro

[0041] 3. Experimental process:

[0042] 3.1 Weigh an appropriate amount of cocamidopropyl betaine and sodium lauroyl sarcosinate

[0043] 3.2 Weigh the deionized water, slowly add the mixture of cocamidopropyl betaine and sodium lauroyl sarcosinate into the deionized water while stirring, and stir evenly

[0044] 3.3 Add citric acid to adjust pH

[0045] 3.4 Put the sample in the incubator for 24 hours and take it out. Take an appropriate amount of sample ...

Embodiment 2

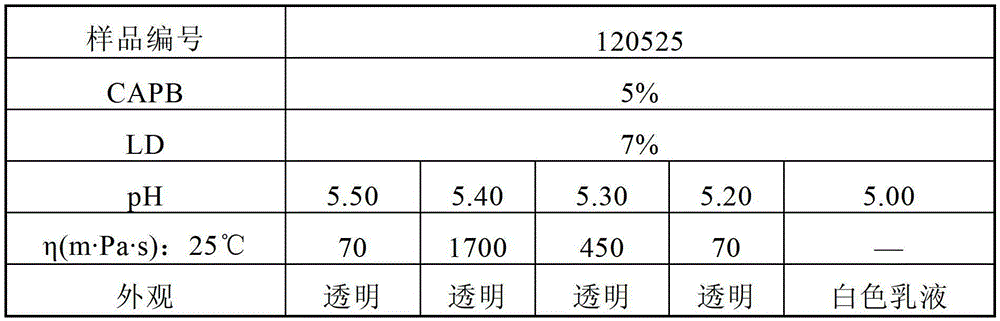

[0052] Embodiment 2: Thickening experiment when the ratio of CAPB and LD is 5%:7%

[0053] The system of cocamidopropyl betaine and sodium lauroyl sarcosinate was prepared according to the method described in Example 1, except that the ratio of CAPB to LD was 5%:7%. The results are shown in Table 2.

[0054] Table 2: Viscosity measurement results of CAPB and LD with a ratio of 5%:7%

[0055]

[0056] The results showed that when the percentage of active substances of cocamidopropyl betaine and sodium lauroyl sarcosinate was used at 5%:7%, the maximum viscosity appeared at pH5.40, and the viscosity was 1700m·Pa·s.

Embodiment 3

[0057] Embodiment 3: Thickening experiment when the ratio of CAPB and LD is 6%:6%

[0058] The system of cocamidopropyl betaine and sodium lauroyl sarcosinate was prepared according to the method described in Example 1, except that the ratio of CAPB and LD was 6%:6%. The results are shown in Table 3.

[0059] Table 3: Viscosity measurement results of CAPB and LD with a ratio of 6%:6%

[0060]

[0061] The results showed that when the percentage of active substances of cocamidopropyl betaine and sodium lauroyl sarcosinate was used at 6%:6%, the maximum viscosity appeared at pH5.40, and the viscosity was 2900m·Pa·s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com