Ultrahigh-toughness alkali-activated shotcrete and preparation method thereof

A shotcrete and ultra-high toughness technology, applied in the field of building materials, can solve the problems of large cement consumption and poor durability, and achieve the effects of increasing the consistency of the slurry, reducing the dosage and having a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

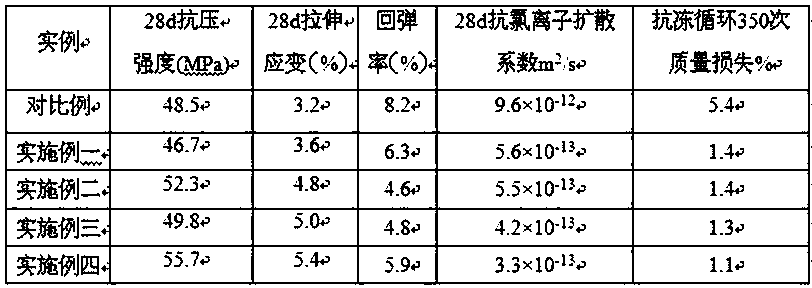

Examples

preparation example Construction

[0035] It should be noted that the preparation method of embodiments 1 to 3 is the same, as follows:

[0036] Step 1) Soak high-strength or ultra-high-strength polyvinyl alcohol fibers and polyethylene fibers in calcium hydroxide solution;

[0037] Step 2) Use ultrasonic vibration to disperse nano-alumina evenly in water;

[0038] Step 3) dissolving sodium hydroxide solution, sodium silicate solution, aluminum sulfate, and water reducing agent in the aqueous solution prepared in step 2);

[0039] Step 4) Weigh ultrafine lithium slag powder, slag powder, stone powder waste, Portland cement, nickel slag sand, copper slag sand, thickener in proportion and stir evenly;

[0040] Step 5) Add the aqueous solution prepared in step 3) to the material prepared in step 4) and stir, and add the fiber prepared in step 1) evenly during the stirring process, and the stirring time is 2 to 5 minutes.

Embodiment 1

[0042] The sprayed concrete of the present invention consists of the following parts by mass: 600 m 2 / kg lithium slag powder 400 parts, slag powder 100 parts, stone factory cutting stone powder waste 50 parts, ordinary portland cement 60 parts, sodium hydroxide solution 10 parts, sodium silicate solution 50 parts, aluminum sulfate 1 part, nano 5 parts of alumina, 900 parts of nickel slag sand, 600 parts of copper slag sand, 3 parts of wheat straw plant fiber powder, 1 part of polyvinyl alcohol fiber, 3 parts of polycarboxylate superplasticizer; 350 parts of water.

Embodiment 2

[0044] The sprayed concrete of the present invention consists of the following parts by mass: 800 m 2 / kg ultrafine lithium slag powder 200 parts, slag powder 200 parts, stone factory cutting stone powder waste 100 parts, ordinary Portland cement 30 parts, sodium hydroxide solution 70 parts, sodium silicate solution 15 parts, aluminum sulfate 10 parts 1 part of alumina, 400 parts of nickel slag sand, 300 parts of copper slag sand, 6 parts of corn straw plant fiber powder, 10 parts of polyethylene fiber, 10 parts of polycarboxylate superplasticizer, 200 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com