Penetrating non-color-sticky digital printing paste

A digital printing, non-stick color technology, applied in the field of paste, can solve the problems of light color, easy to stick color, poor permeability, etc., and achieve the effect of high coloring rate, long definition and improved permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

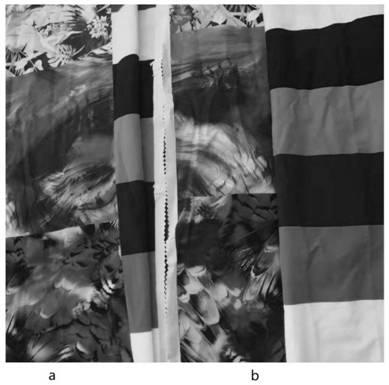

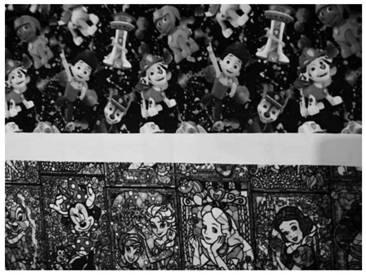

Image

Examples

Embodiment 1

[0056] Embodiment 1 provides a kind of penetrating and non-sticky digital printing paste, comprising the following preparation raw materials in mass percentage: sodium alginate 0.2%, polypropylene glycol 0.2%, acetic acid 0.05%, sodium sulfate 0.5%, methyl cellulose supplement margin.

[0057] The sodium alginate is M-16 of Suzhou Runbao Chemical Co., Ltd.

[0058] The polypropylene glycol is a mixture of PPG-600 and PPG-3000 from Hai'an Petrochemical Plant in Jiangsu Province.

[0059] The mass ratio of PPG-600 and PPG-3000 is 8:1.

[0060] The methyl cellulose is a mixture of 55HD50 and 55HD400 from Nanjing Lihongde Trading Co., Ltd.

[0061] The mass ratio of the 55HD50 and 55HD400 is 1:10.

[0062] The preparation method of the above-mentioned permeable and non-sticky digital printing paste comprises the following steps: dilute the polypropylene glycol with chloroform, heat to boiling, then add sodium alginate, acetic acid, sodium sulfate, methyl cellulose, and stir whi...

Embodiment 2

[0064] Example 2 is basically the same as Example 1, the only difference is that the non-sticky digital printing paste penetrates, including the following preparation raw materials in mass percentages: 0.8% sodium alginate, 0.5% polypropylene glycol, 0.1% acetic acid, sodium sulfate 1 %, methyl cellulose makes up the balance.

Embodiment 3

[0066] Embodiment 3 is basically the same as Embodiment 1, the only difference being that the non-sticky digital printing paste penetrates, including the following preparation raw materials in mass percentage: 0.1% sodium alginate, 0.1% polypropylene glycol, 0.01% acetic acid, sodium sulfate 1% %, methyl cellulose makes up the balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com