Invariant color oil-based ink containing abelmoschus manihot extract and preparation method of ink

A technology of hollyhocks and oil-based ink, applied in the field of printing ink, can solve the problems of losing artistic value and use value, and achieve the effect of bright patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The ink preparation process can be divided into five stages: batching, liquid binder preparation, stirring pre-dispersion, grinding fine dispersion and adjusting stirring.

[0038] 1) Ingredients: Colorant, ink resin, vegetable oil, mineral oil, marshmallow flower extract, additives, varnish are prepared according to weight percentage;

[0039] 2) Preparation of liquid binder: heat ink resin, vegetable oil, and mineral oil to 200-300°C until the materials are dissolved to obtain a binder;

[0040] 3) Stirring pre-dispersion: Stir the binder and colorant for pre-dispersion and rough grinding;

[0041] 4) Grinding and fine dispersion: then finely grind the above materials until the fineness of the ink material is less than 10 microns;

[0042] 5) Adjust the stirring: add the extract of hollyhock flower, additives, and varnish, and stir evenly to obtain the product.

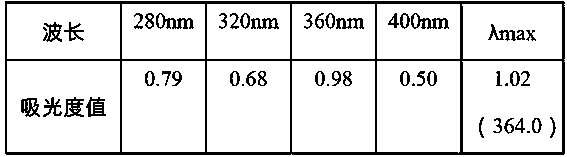

[0043] The extract of hollyhock flower (total flavonoids) can be prepared in various ways, and the preferr...

Embodiment 1

[0054] Example 1 Non-discoloration oil-based ink with hollyhock flower extract (blue)

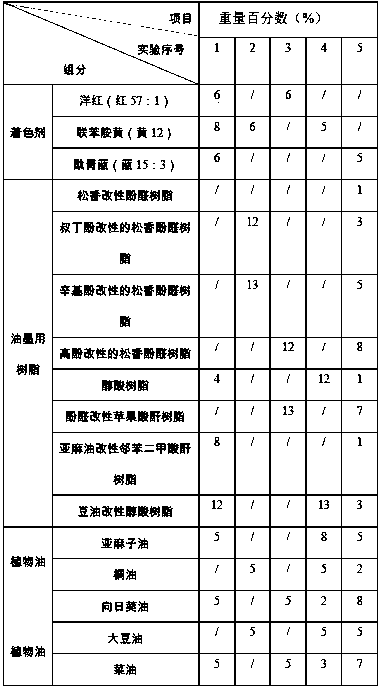

[0055] Raw materials: the weight percentage of specific components is shown in Table 3.

[0056] The composition of the oily ink of table 3 embodiment 1

[0057]

[0058] Preparation process: In the mixing tank, according to the above-mentioned feeding ratio, add 18 grams of soybean oil, 30 grams of mineral oil D110, and 30 grams of alcohol-soluble rosin resin PH103 in sequence, heat until the materials are dissolved, and prepare the connecting material; then connect the above liquid Add the material to another mixing tank, turn on the mechanical stirring, and add 12 grams of pigments according to the above proportion. Keep stirring for 60 minutes for pre-dispersion to become a slurry with better fluidity; the stirred material is pressed into the three-roller machine, and after several times of grinding and fine dispersion, the large particles are ground into small particles until the ...

Embodiment 2

[0059] Example 2 With the weight percent batching of each component shown in table 4:

[0060] The composition of the oily ink of table 4 embodiment 2

[0061]

[0062] For the preparation process, refer to the preparation process of Example 1.

[0063] The light fastness of the ink (non-decolorization) is measured by a professional measurement method for printed matter and printing ink. The principle is: under the specified conditions, the test sample and the blue wool standard sample are exposed to the xenon arc lamp at the same time, and the light fastness is evaluated by finding a level similar to the test sample in the blue wool standard sample. Under the condition that other formulas remain unchanged, the light fastness of the non-discoloration oil-based ink added with hollyhock flower extract is 1-3 grades higher than that of the oil-based ink without added hollyhock flower extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com