Preparation method of synthetic quartz jade

A jade and quartz technology, applied in the field of artificial quartz jade and its production, can solve the problems of low hardness, serious product homogeneity, and weak product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0152] Embodiment 1. a kind of preparation method of artificial quartz jade red powder beauty, comprises the steps:

[0153] Step 1: Weigh the color essence, resin (198), OT oxidant, room temperature curing agent tert-butyl peroxide-2-ethylhexanoate, silane coupling agent, UV531 and quartz sand in proportion to fully mix in a stirring pot Mix well and mark as raw material ①, ②, ③;

[0154] Raw material ① formula

[0155]

[0156] Raw material ② formula

[0157]

[0158]

[0159] Raw material ③ formula

[0160]

[0161] Step 2: Take industrial pigments and mix well in proportion to make stripes. Raw material: A white stripes;

[0162] A white grain formula

[0163]

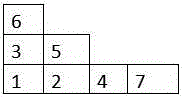

[0164] Step 3: Take the raw materials ①, ②, ③ obtained in step 1 and the various stripes obtained in step 2 and mix them thoroughly in proportion and record them as raw materials 1-7;

[0165]

[0166]

[0167] Step 4: Take the raw materials 1-7 prepared in step 3 and cut them out, and the...

Embodiment 2

[0168] Embodiment 2. A kind of preparation method of man-made quartz jade pity fragrance cherish jade, comprises the steps:

[0169] Step 1: Weigh the color essence, resin (198), OT oxidant, room temperature curing agent tert-butyl peroxide-2-ethylhexanoate, silane coupling agent, UV531 and quartz sand in proportion to fully mix in a stirring pot Mix well and mark as raw material ①, ②, ③;

[0170] Raw material ① formula

[0171]

[0172] Raw material ② formula

[0173]

[0174]

[0175] Raw material ③ formula

[0176]

[0177] Step 2: Take industrial pigments and mix well in proportion to make stripes. Raw material: A white stripes;

[0178] A white grain formula

[0179]

[0180] Step 3: Take the raw materials ①, ②, ③ obtained in step 1 and the various stripes obtained in step 2, fully mix them in proportion and record them as raw materials 1-6;

[0181]

[0182] Step 4: Take the raw materials 1-6 prepared in step 3 and cut them, the cutting order: raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com