Combination type substation

A substation and combined technology, applied in the field of substations, can solve the problems of low processing accuracy and processing efficiency, time-consuming and labor-intensive parts, increase labor costs and welding costs, etc., to reduce VOC content, improve processing accuracy and processing efficiency, avoid The effect of welding cost and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

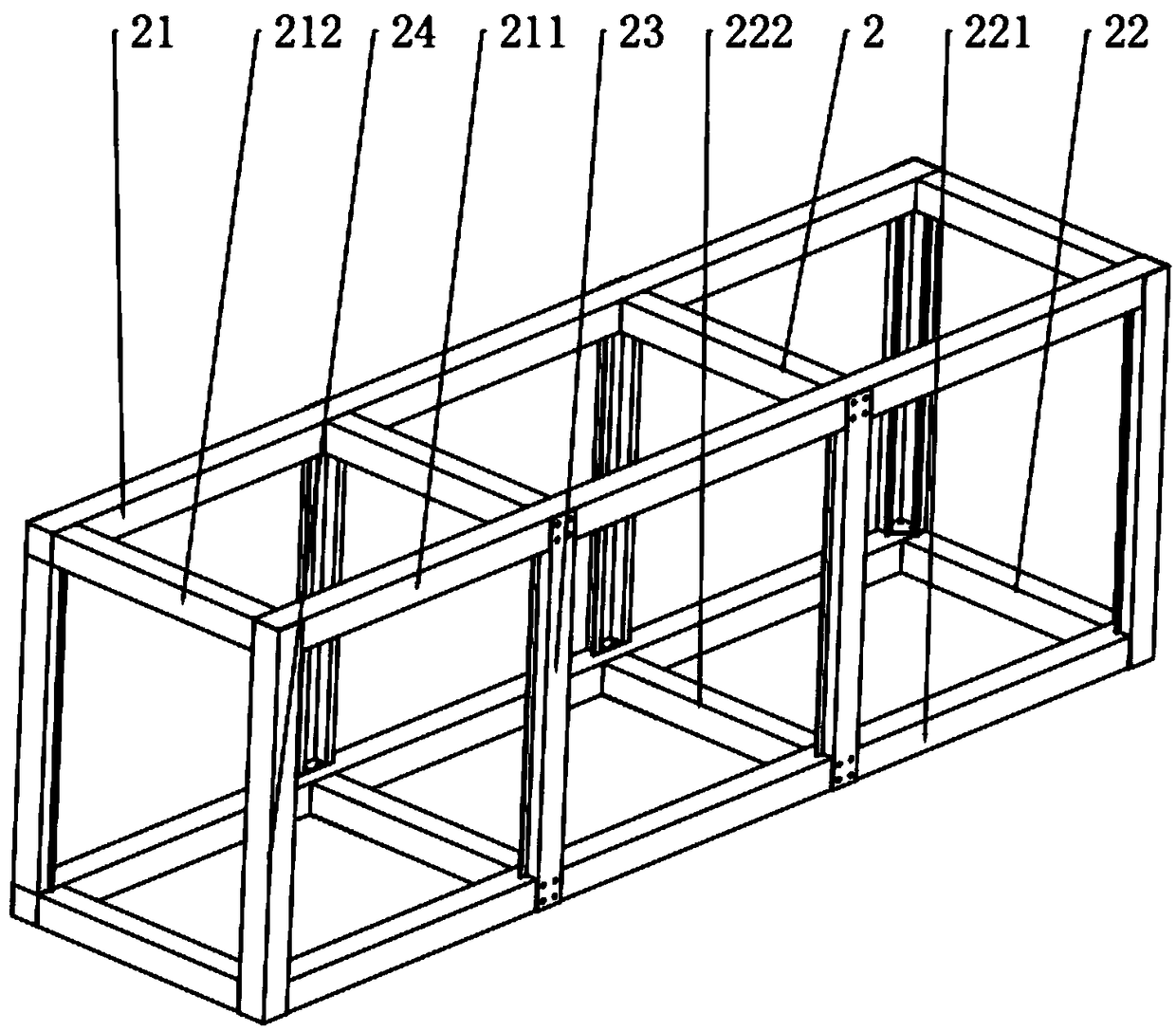

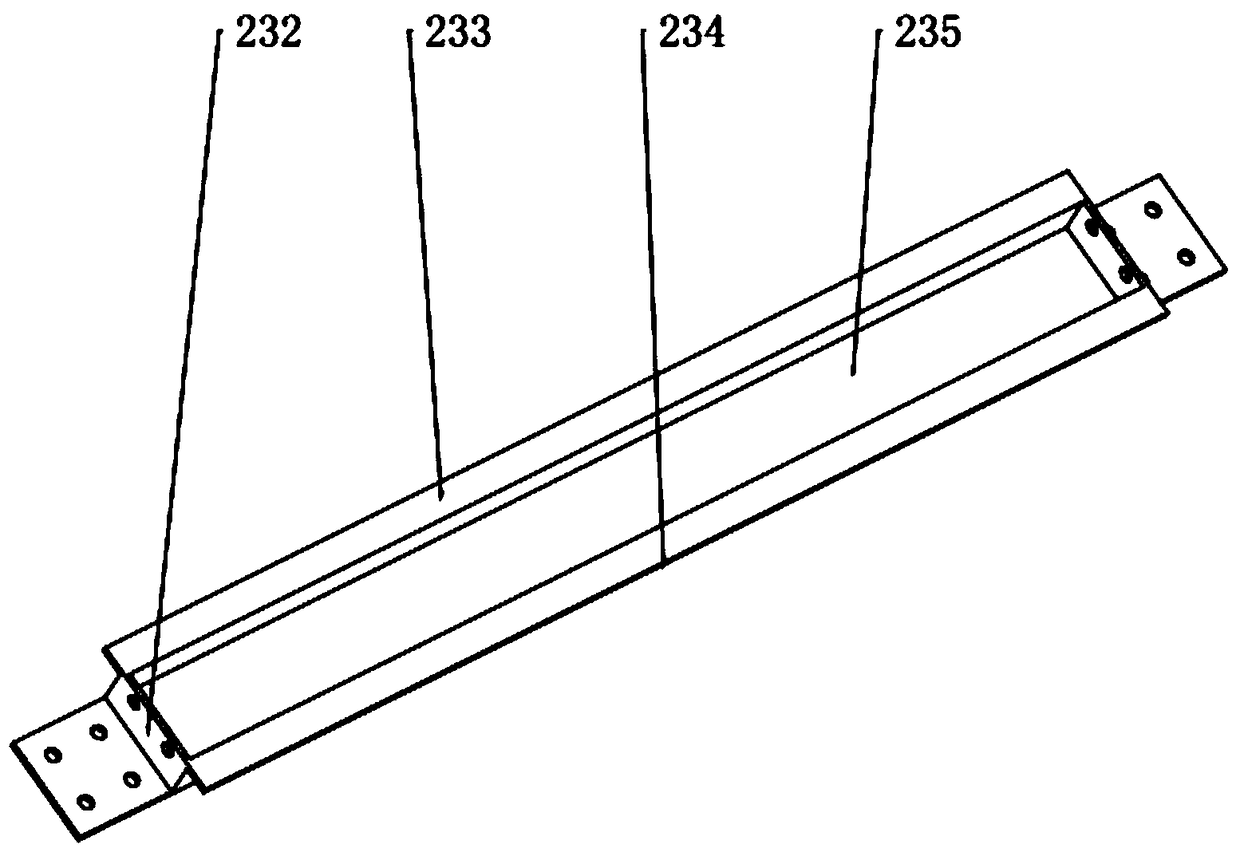

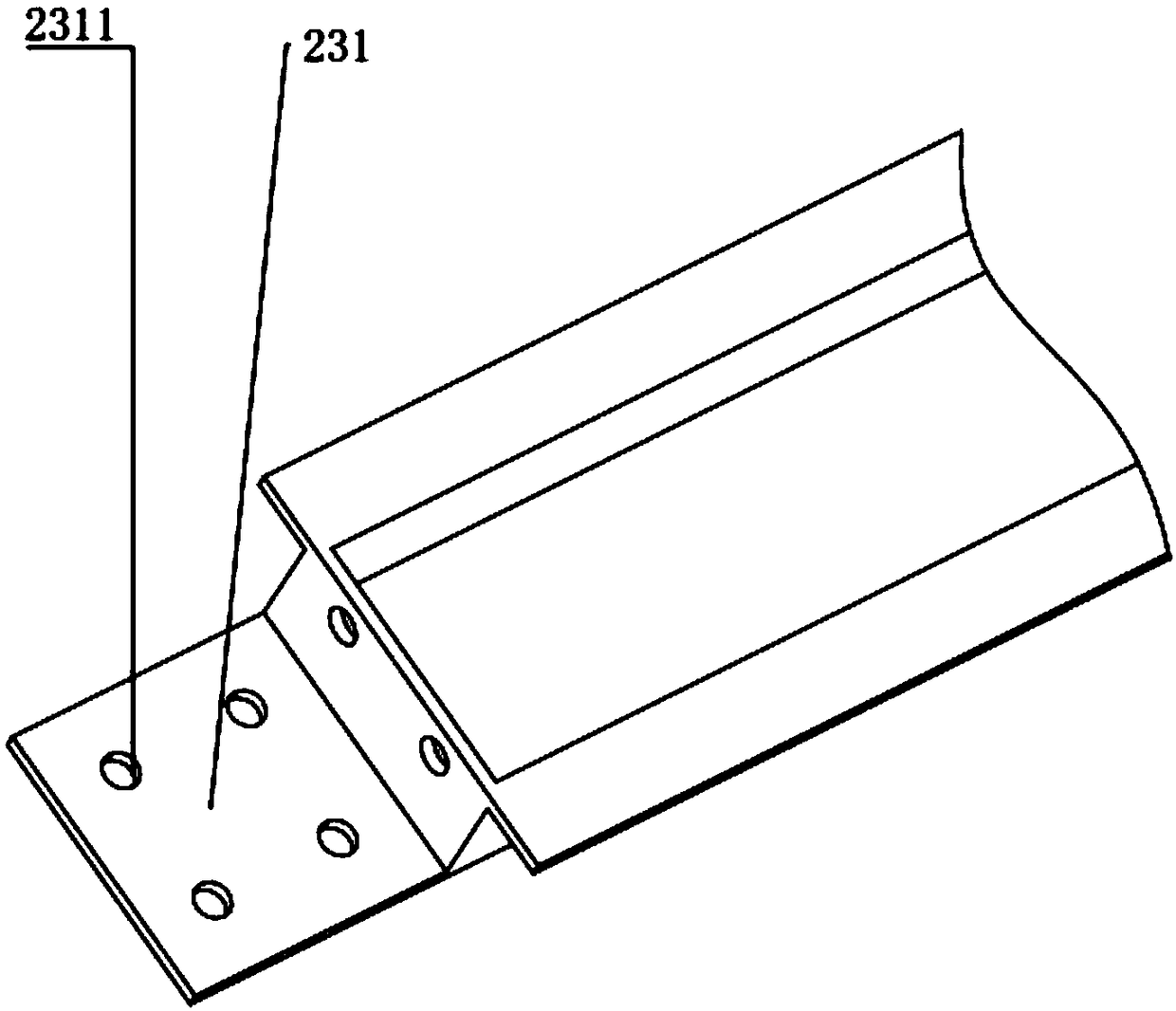

[0049] A combined substation, including a chassis 1, a box body 2, and a top cover 3. The box body 2 includes an upper support 21, a lower base 22, a column 23, and a corner column 24. The upper part of the box body 2 is provided with a top cover 3, and the box body The bottom part of 2 is provided with chassis 1; The inner wall of described chassis, casing, top cover is all sprayed with zinc-rich paint, and the surface of described zinc-rich paint is sprayed with anti-corrosion material layer, and described anti-corrosion material comprises the raw material of following parts by weight Prepared: water-based resin 55, zinc tripolyphosphate 10, toluenesulfonic acid 6, hydroxyethylidene diphosphonic acid 6, XR-424 additive 7, fumaric acid 2, dimethyl sulfoxide 1, deionized water 15. Wherein, the water-based resin is a mixture of water-based epoxy acrylic resin and water-based double-crosslinked acrylic emulsion, and the weight ratio of the two is 3:1; after the anti-corrosion ma...

Embodiment 2

[0054] The combined substation of this embodiment has the same structure as that of Embodiment 1, the difference is that:

[0055] The anti-corrosion material is prepared from the following raw materials in parts by weight: water-based resin 75, zinc tripolyphosphate 20, toluenesulfonic acid 10, hydroxyethylidene diphosphonic acid 9, XR-424 additive 10, fumaric acid 5, Dimethyl sulfoxide 3, deionized water 25. Wherein, the water-based resin is a mixture of water-based epoxy acrylic resin and water-based double-crosslinked acrylic emulsion, and the weight ratio of the two is 5:1; after the anti-corrosion material layer is sprayed, the whole equipment is placed in 55°C hot air 4 hours under conditions. The preparation method of the anti-corrosion material includes the following steps: S1. After preparing the materials, sequentially add deionized water, zinc tripolyphosphate, toluenesulfonic acid, hydroxyethylidene diphosphonic acid, and XR-424 auxiliary agent into the reaction ...

Embodiment 3

[0057] The combined substation of this embodiment has the same structure as that of Embodiment 1, the difference is that:

[0058] The anti-corrosion material is prepared from the following raw materials in parts by weight: water-based resin 65, zinc tripolyphosphate 15, toluenesulfonic acid 8, hydroxyethylidene diphosphonic acid 7, XR-424 additive 9, fumaric acid 3, Dimethyl sulfoxide 2, deionized water 20. Wherein, the water-based resin is a mixture of water-based epoxy acrylic resin and water-based double-crosslinked acrylic emulsion, and the weight ratio of the two is 4:1; after the anti-corrosion material layer is sprayed, the whole equipment is placed in a hot air at 50°C 3.5 hours under conditions. The preparation method of the anti-corrosion material includes the following steps: S1. After preparing the materials, sequentially add deionized water, zinc tripolyphosphate, toluenesulfonic acid, hydroxyethylidene diphosphonic acid, and XR-424 auxiliary agent into the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com