Multivariable intelligent fuzzy control system of double-end-face grinding machine

A technology of fuzzy control system and intelligent controller, applied in the direction of grinding machine tools, grinding devices, manufacturing tools, etc., can solve the problems of batch height difference, high operator requirements, no consideration of temperature, interference, etc., to achieve processing efficiency and processing The effect of precision improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the drawings and specific implementations of the specification.

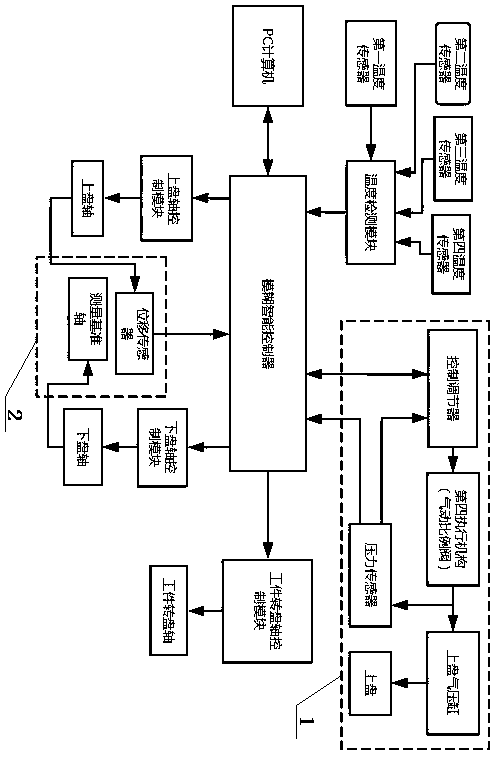

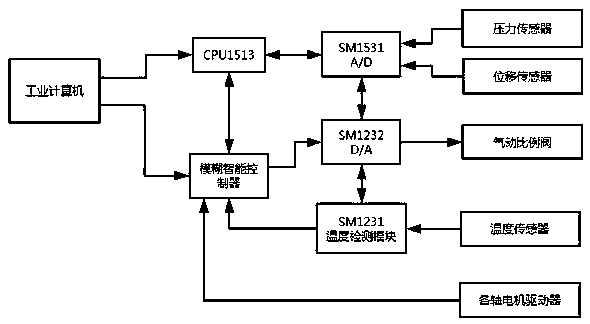

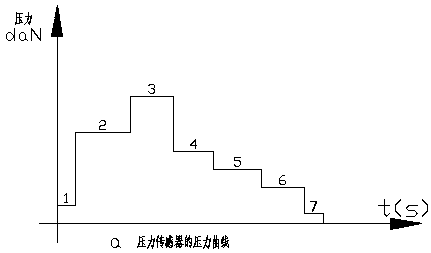

[0025] Such as figure 1 As shown, a multi-variable intelligent fuzzy control system for a double-end face grinding machine includes a fuzzy intelligent controller, an industrial computer, a temperature detection module, a pressure control module 1, an upper shaft control module, a lower shaft control module, and a workpiece turntable Axis control module and workpiece measurement module 2. The fuzzy intelligent controller is a combination of software modules composed of software modules. Its input ends are respectively connected to the temperature detection module and workpiece measurement module 2, and its output ends are respectively connected to the upper shaft control The module, the lower plate axis control module, and the workpiece turntable axis control module are connected, and the fuzzy intelligent controller respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com