Line cutting machine

A cutting machine and cutting mechanism technology, applied in the direction of work accessories, stone processing tools, stone processing equipment, etc., can solve the problems that it is difficult to ensure the consistency of finished products, the accuracy of line processing is easily affected by human factors, and the processing efficiency of manual operation is low. , to achieve the effects of reducing learning costs, realizing wallboard processing procedures, improving processing efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention discloses a wire cutting machine. The specific implementation of the invention will be further described below in combination with preferred embodiments.

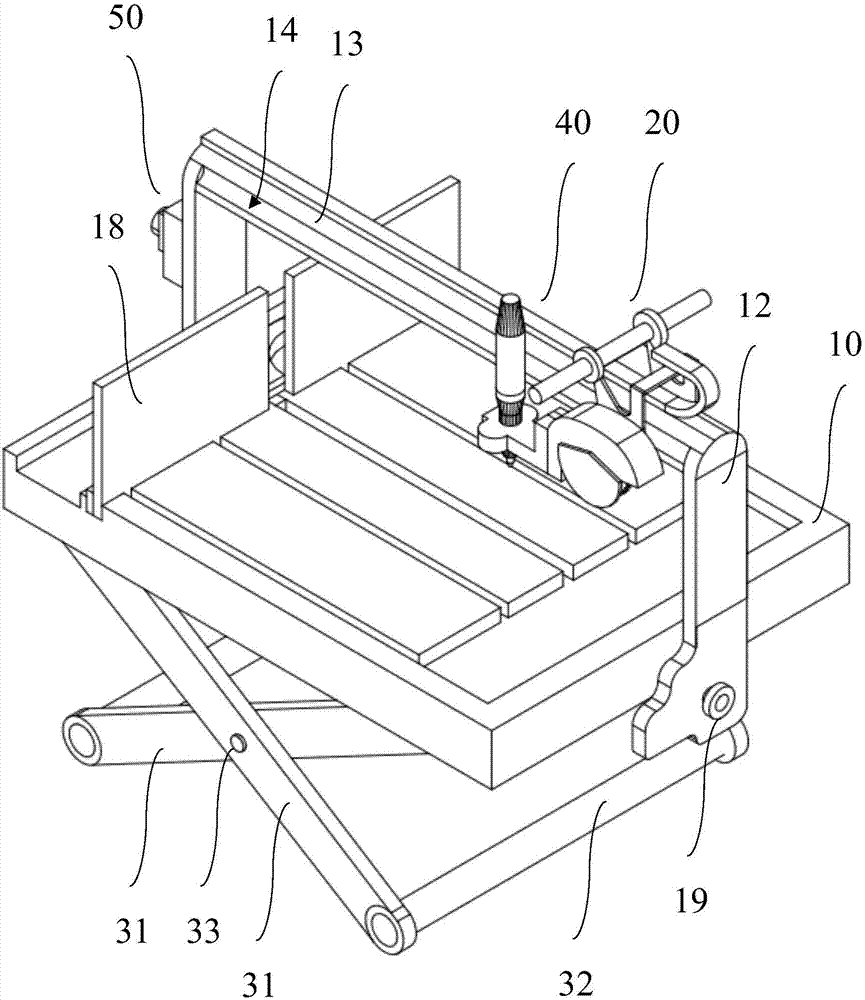

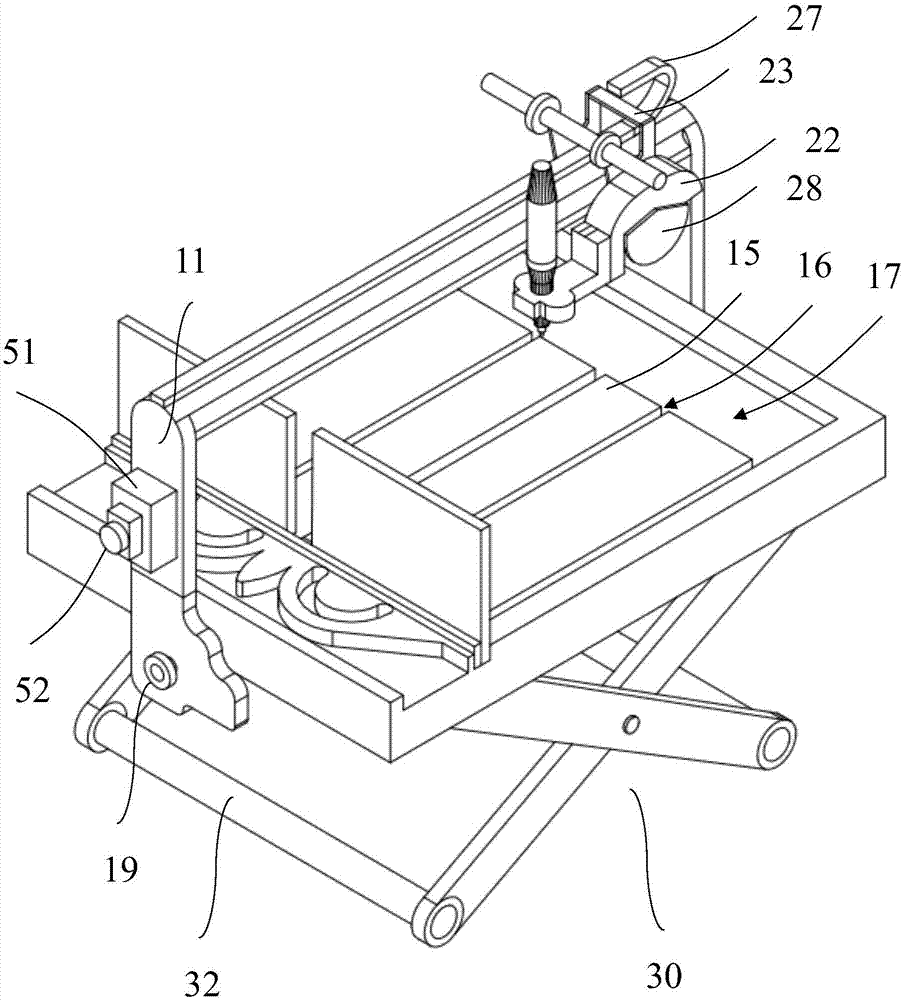

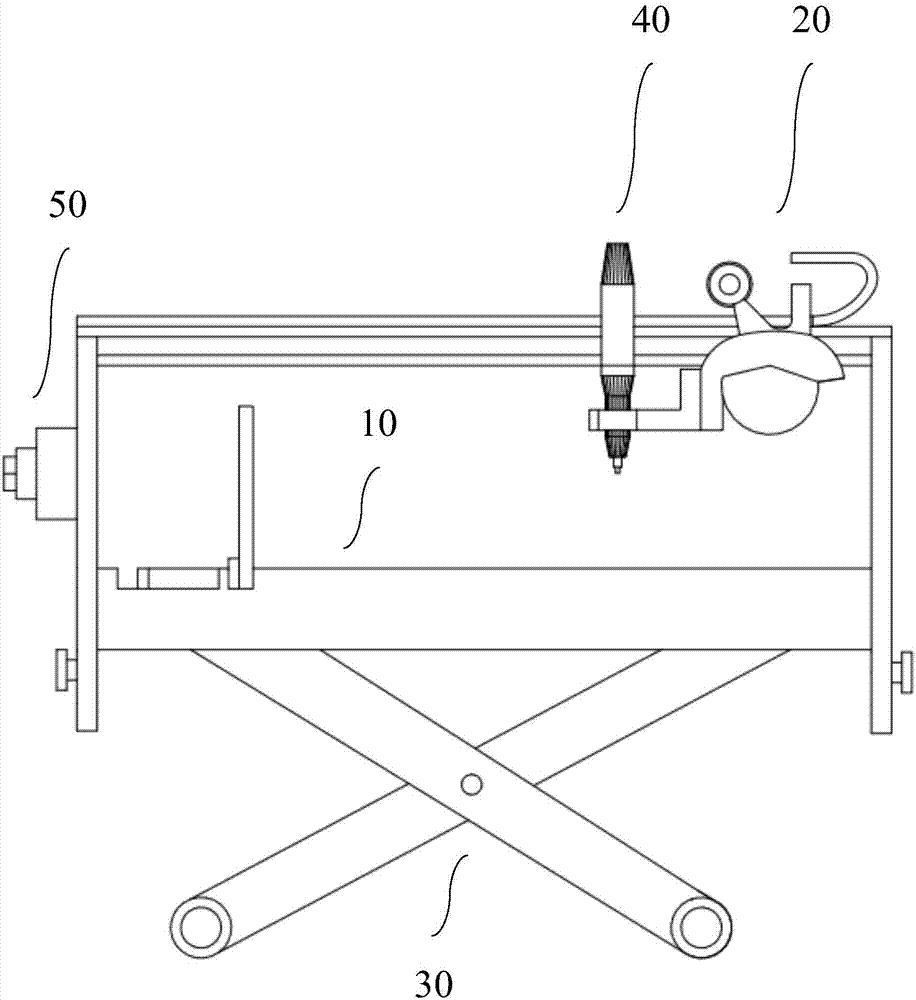

[0026] see attached Figure 1 to Figure 3 , respectively show the overall structure of the wire cutting machine. Preferably, the line cutting machine is provided with a table body 10 and a bracket 11 fixedly connected with the table body 10; the line cutting machine includes a cutting mechanism 20, which is slidably mounted on the bracket 11, and the cutting The mechanism 20 performs mechanical processing such as line cutting on the wallboard (wall / wall) to be cut; the line cutting machine is also provided with a lifting mechanism 30, and the lifting mechanism 30 is fixedly connected with the table body 10, and the lifting mechanism 30 It is used to adjust the height of the table body 10 from the ground.

[0027] see attached Figure 4 , Figure 4 A partially enlarged structure of the cutting mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com