Determination method of first initial side surface of fly-cut monocrystalline germanium two-dimensional six-surface rotating drum

A determination method, single crystal germanium technology, applied in the field of mechanical processing, can solve the problem of not considering the periodic change law of mechanical anisotropy of single crystal germanium material, lack of crystal orientation process and process optimal matching process, ultra-precision fly-cutting processing Low efficiency and other problems, to achieve the effect of getting rid of complex operation process and positioning error, easy for operators to master, and simple and easy to understand orientation scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technology of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] Such as figure 1 , 2 As shown, the method for determining the first initial side surface of the fly-cut single crystal germanium two-dimensional six-sided drum of the present invention, the steps of the method for determining are:

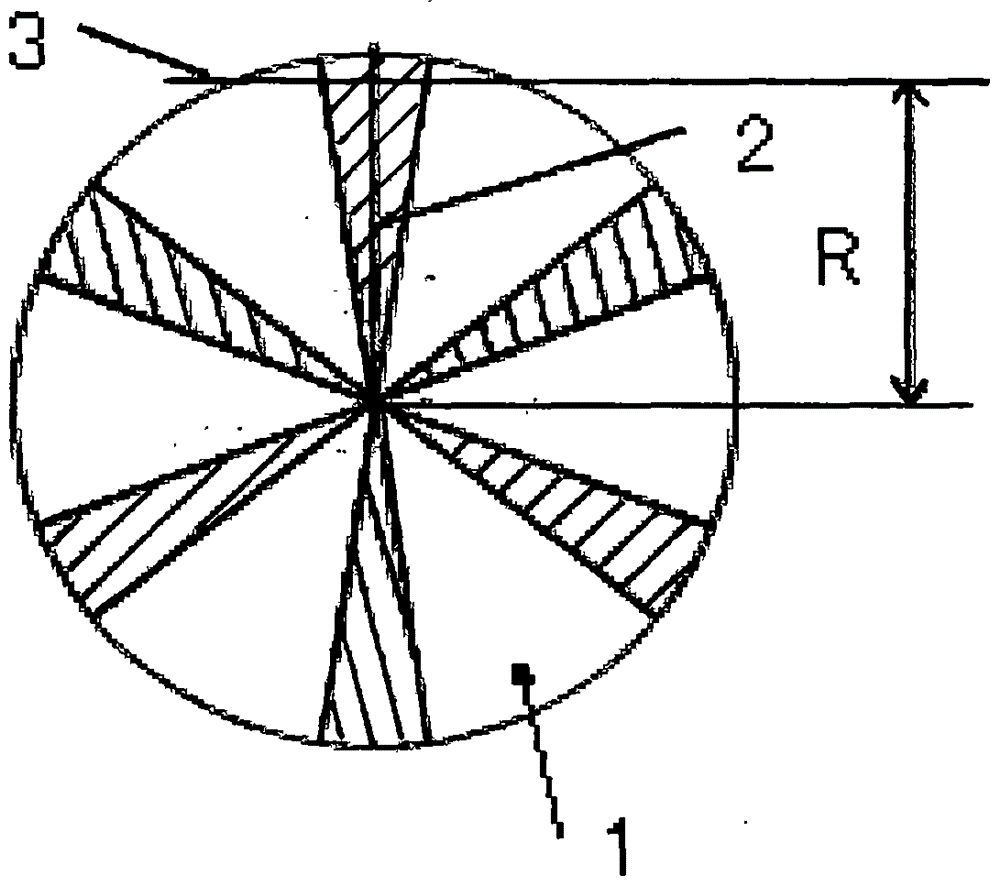

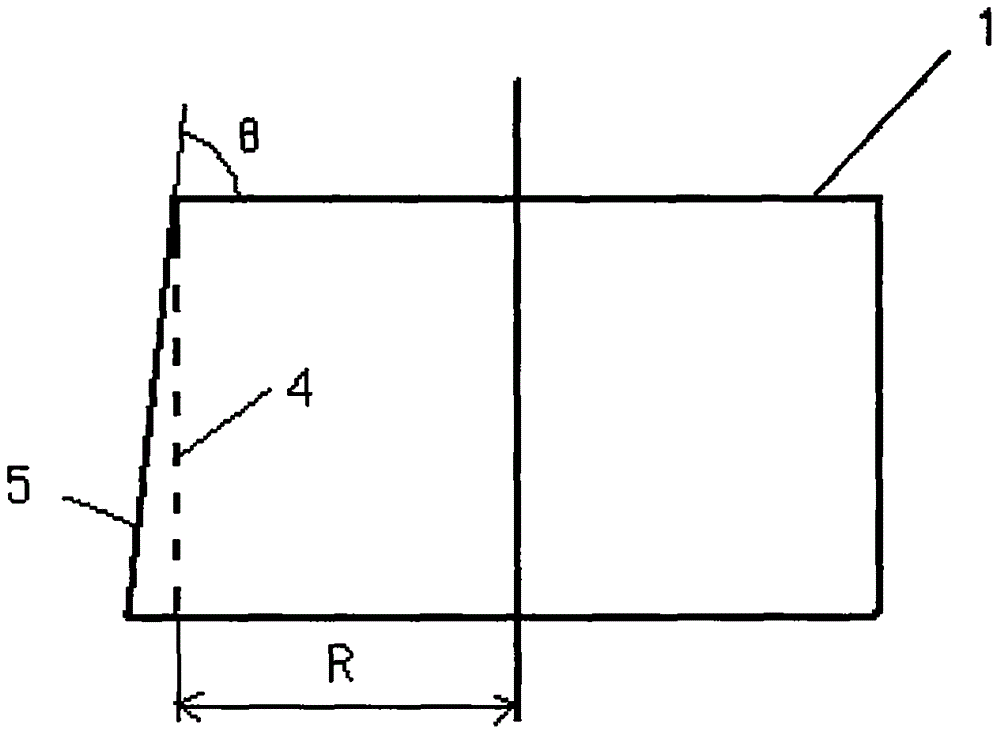

[0020] S1. Cut out the upper and lower parallel reference planes from the single crystal germanium cylindrical bar growing along the single crystal germanium crystal plane, figure 1 Among them, 1 shows the upper reference plane of the single crystal germanium cylindrical bar, and the bar has enough cutting allowance;

[0021] S2. Roughly turn the upper reference plane 1 of the single crystal germanium cylindrical bar into an anisotropic periodic petal distribution feature;

[0022] S3. After rough turning the end face, take the radial centerline 2 of any white spot petals on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com