Method and system for treating VOCs gas in sewage treatment plant

A technology for sewage treatment plants and waste water treatment systems, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of high investment and operating costs, and achieve the effects of reducing operating costs, reducing usage, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

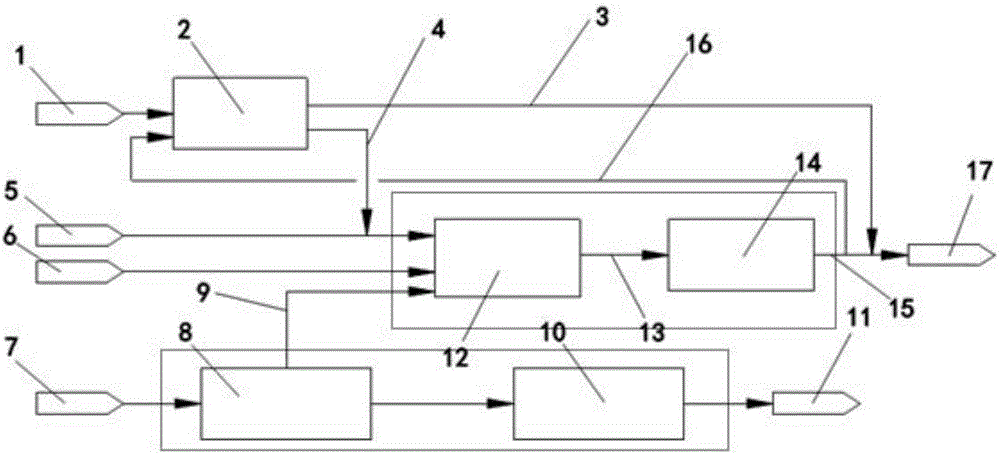

[0027] The specific process is as figure 1 shown. After mixing the low-concentration VOCs gas produced by the aeration tank, sludge thickening tank and flow sedimentation tank of a sewage treatment plant (the gas volume is 76000Nm 3 / h, the concentration of non-methane total hydrocarbons is 104mg / Nm 3 , calculated as propane) into the rotary adsorption system for concentration to obtain 6000Nm 3 / h high-concentration VOCs gas (non-methane total hydrocarbon concentration is 1310mg / Nm 3 , calculated as propane); then with the 4000Nm generated by the sludge dewatering machine room 3 / h high-concentration VOCs gas (non-methane total hydrocarbon concentration is 3200mg / Nm 3 , calculated as propane) are merged into the combustion and waste heat recovery system. In this case, regenerative combustion is adopted, and the combustion temperature is 600°C.

[0028] The wastewater treatment system has a wastewater treatment capacity of 20.8m 3 / h, 1050Nm after anaerobic treatment 3 ...

Embodiment 2

[0032] The specific process is as figure 1 shown. After mixing the low-concentration VOCs gas produced by the aeration tank, the sludge concentration tank and the flow sedimentation tank of another sewage treatment plant (the gas volume is 98000Nm 3 / h, the concentration of non-methane total hydrocarbons is 135mg / Nm 3 , calculated as propane) into the rotary adsorption system for concentration to obtain 6000Nm 3 / h high-concentration VOCs gas (non-methane total hydrocarbon concentration is 2200mg / Nm 3 , calculated as propane); and then with the 5000Nm generated by the sludge dewatering machine room 3 / h high-concentration VOCs gas (non-methane total hydrocarbon concentration is 2700mg / Nm 3 , calculated as propane) is merged into the combustion and waste heat recovery system. In this case, thermal combustion is adopted, the combustion temperature is 810°C, the residence time is 3.4s, and the air excess coefficient is 23%.

[0033] The wastewater treatment system has a wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com