Method for separating mercury and cracking organic substance

A technology of organic substances and substances, which is applied in high temperature steam to separate mercury, treat soil modification and waste treatment, crack dioxin and organic substances, and can solve the problems of expensive equipment, energy consumption, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

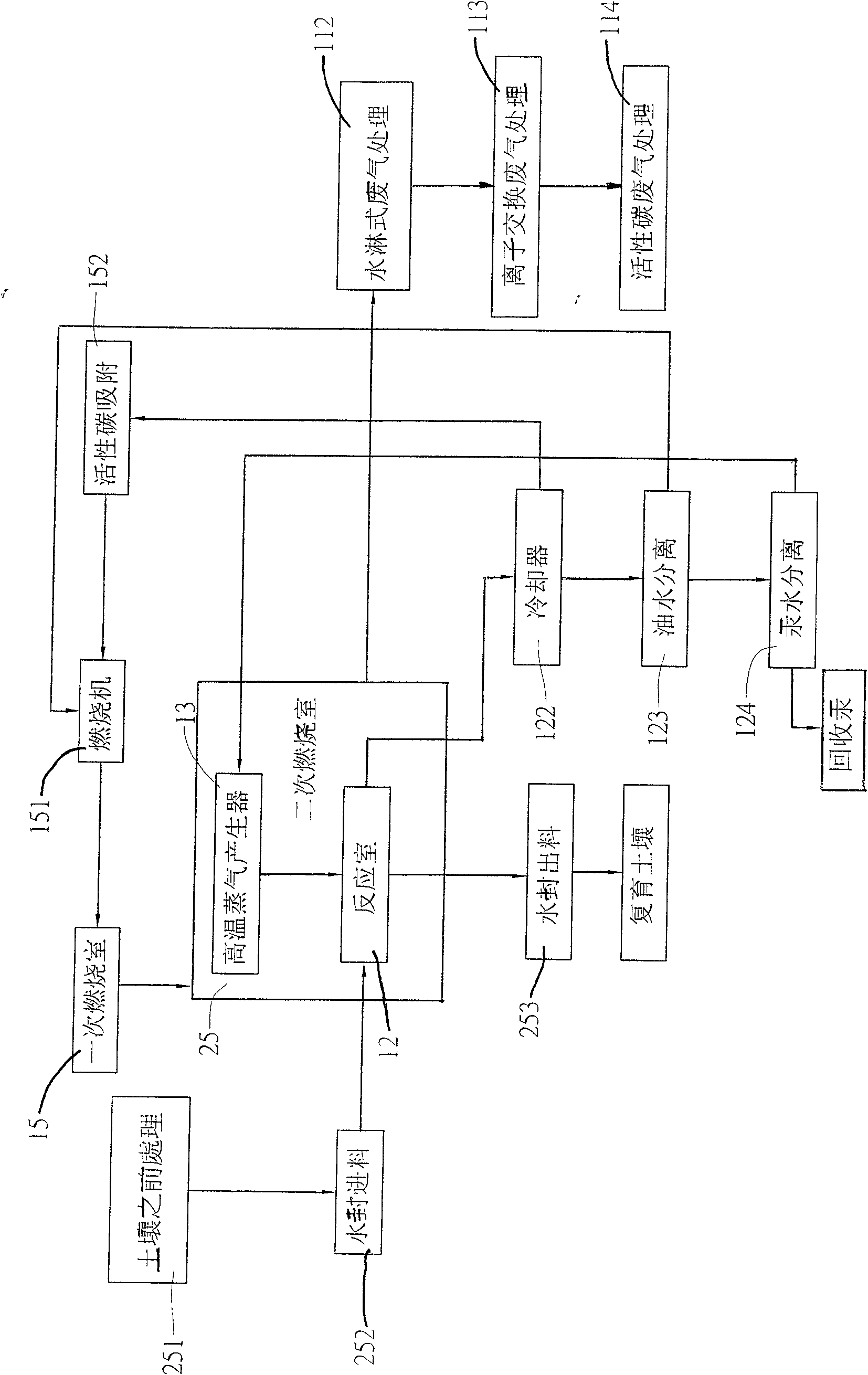

[0047] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

[0048] The present invention provides a method for separating mercury, cracking dioxin and organic substances by using high temperature steam and circulating heat source, please refer to figure 1 , is a preferred embodiment of the present invention, as shown in the figure, its processing flow is described as follows:

[0049] Soil pretreatment 251 Because the organic matter contained in the soil is low, energy consumption is required in the treatment. In order to reduce the use of energy and make the modified soil contain a large amount of activated carbon, it is necessary to add carbon-containing substances when treating the soil. This carbonaceous substance can be the following substances: substances containing organic matter; substances containing dioxin; substances containing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com