Method and process for advanced treatment of well drilling effluent

A technology of drilling waste fluid and process, which is applied in the fields of energy waste water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

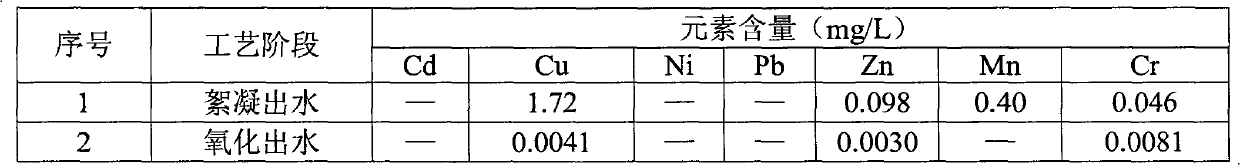

[0021] Add 12g / L inorganic coagulant polyaluminium chloride and 100mg / L organic flocculant cationic polyacrylamide to waste organic silicon drilling fluid discharged from an oil field, stir at high speed (300r / min) for 90s, and stir at low speed (20r / min) 10 to 15 minutes, centrifuge with a centrifuge at 3400r / min for 2 minutes. The residual turbidity of the separated water is 18FTU (10530FTU before treatment), the residual color is 5 times (10000 times before treatment), COD Cr 1100mg / L (1.4×10 before treatment 4 mg / L), and the removal rate reached more than 99%. Adjust the pH value of the separated water to 4, then add hydrogen peroxide (30%) 7ml / L, 1.5g / L ammonium persulfate, 0.5mmol / L ferrous sulfate, and irradiate with sunlight for 120 minutes at 15-20°C Finally, use lime milk to adjust the pH value to 8-9, and catalyze the oxidation of water COD Cr It is 147.6mg / L; after 120 minutes of irradiation in an externally illuminated photochemical reactor with simulated sunli...

Embodiment 2

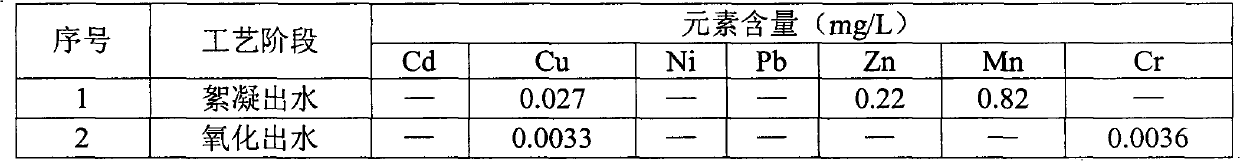

[0026] For waste polymer drilling fluid discharged from an oil field, add 16g / L inorganic coagulant polyaluminum chloride and 120mg / L organic flocculant cationic polyacrylamide, stir at high speed (300r / min) for 90s, and stir at low speed (20r / min) 10 to 15 minutes, centrifuge with a centrifuge at 3400r / min for 2 minutes. The residual turbidity of the separated water is 8FTU (8150FTU before treatment), the residual color is 10 times (8000 times before treatment), COD Cr 730mg / L (6.6×10 before treatment 4 mg / L), and the removal rate reached more than 99%. Adjust the pH value of the separated water to 4, then add hydrogen peroxide (30%) 7ml / L, 1.5g / L ammonium persulfate, 0.5mmol / L ferrous sulfate, and irradiate with sunlight for 120 minutes at 15-20°C Finally, use lime milk to adjust the pH value to 8-9, and catalyze the oxidation of water COD Cr It is 147.2mg / L; after 120 minutes of radiation in an externally illuminated photochemical reactor with simulated sunlight (long-ar...

Embodiment 3

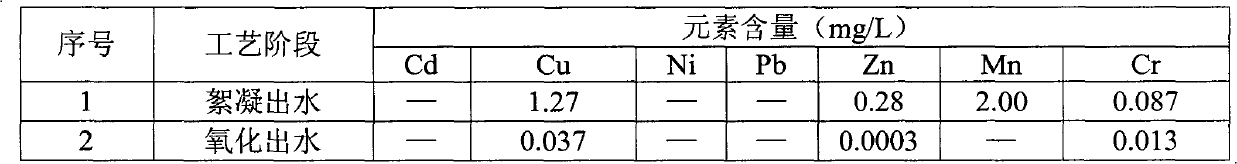

[0031] Add 12g / L inorganic coagulant polyaluminum chloride and 60mg / L organic flocculant cationic polyacrylamide to the waste potassium salt polymer drilling fluid discharged from an oil field, stir at high speed (300r / min) for 90s, and stir at low speed (20r / min ) stirring for 10 to 15 minutes, and centrifuged for 2 minutes with a centrifuge at 3400 r / min. The residual turbidity of the separated water is 8FTU (32600FTU before treatment), the residual color is 20 times (13500 times before treatment), COD Cr 1059.6mg / L (4.4×10 before treatment 4 mg / L), and the removal rate reached more than 99%. Adjust the pH value of the separated water to 4, then add hydrogen peroxide (30%) 7ml / L, 1.0g / L ammonium persulfate, 0.5mmol / L ferrous sulfate, and irradiate with sunlight for 120 minutes at 15-20°C Finally, use lime milk to adjust the pH value to 8-9, and catalyze the oxidation of water COD Cr It is 190.8mg / L; after 120 minutes of irradiation in an externally illuminated photochemic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com