Catalytic ozonation reactor for treatment of external circulating wastewater and wastewater treatment method

A technology of ozone catalytic oxidation and sewage treatment, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of increasing equipment investment and operation difficulty, low sewage treatment efficiency, and pre-oxidation tower efficiency Low-level problems, to achieve the effect of improving the utilization rate of ozone, convenient cleaning, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

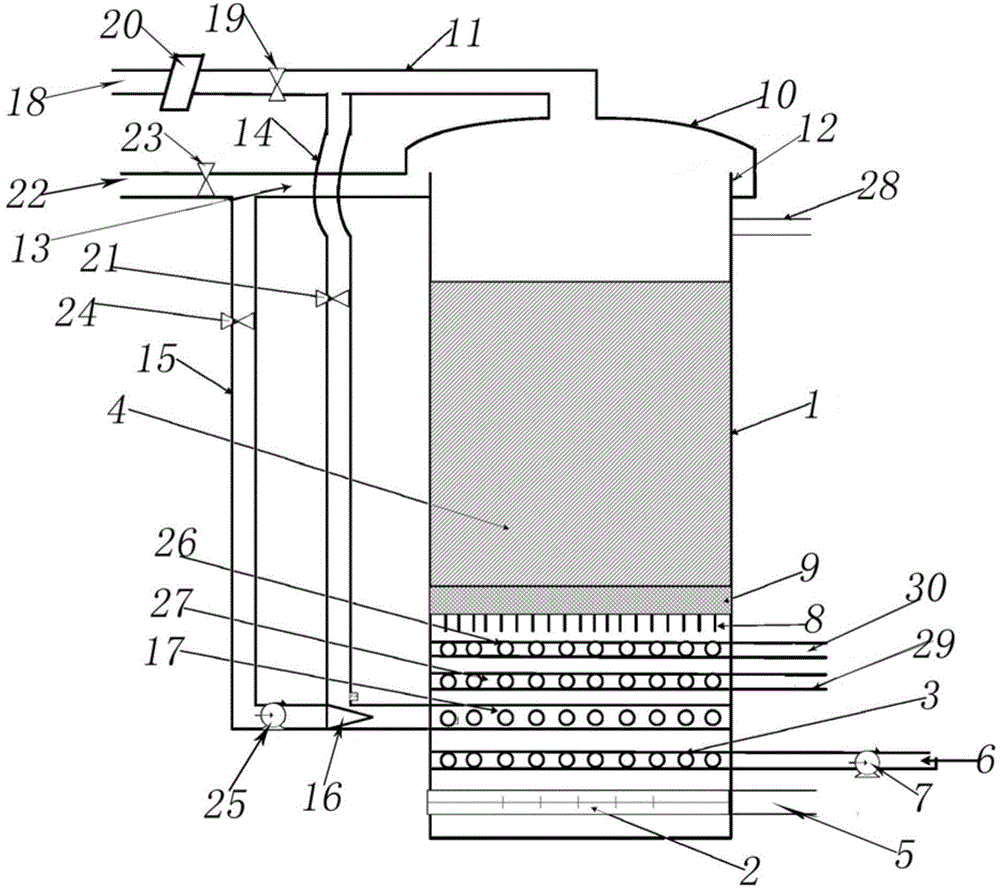

Method used

Image

Examples

Embodiment 1

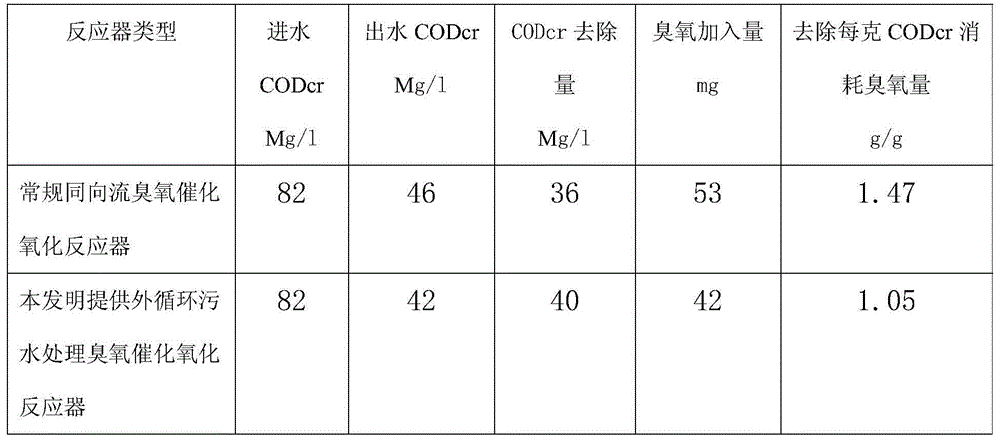

[0047] The CODcr of the secondary sedimentation tank of a sewage treatment plant in a chemical enterprise is between 85 and 96 mg / l, while the local CODcr discharge standard for sewage is less than 50 mg / l. After the sewage is biochemically treated, the BOD of the secondary sedimentation tank 5 Less than 8mg / l, B / C value less than 0.1, it is difficult to biochemically treat sewage. Through investigation and expert demonstration, it is planned to adopt the flocculating sand filter + ozone catalytic oxidation treatment process, and carry out verification and comparison tests. The test results show that the CODcr of the sewage is about 80mg / l after the flocculated sand filtration treatment, and the CODcr of the sewage can reach below 50mg / l after the flocculated sand filtration water is treated by ozone catalytic oxidation. For the catalytic oxidation of ozone, comparative experiments of different reactor types were carried out. The comparative experiments were conducted in the ex...

Embodiment 2

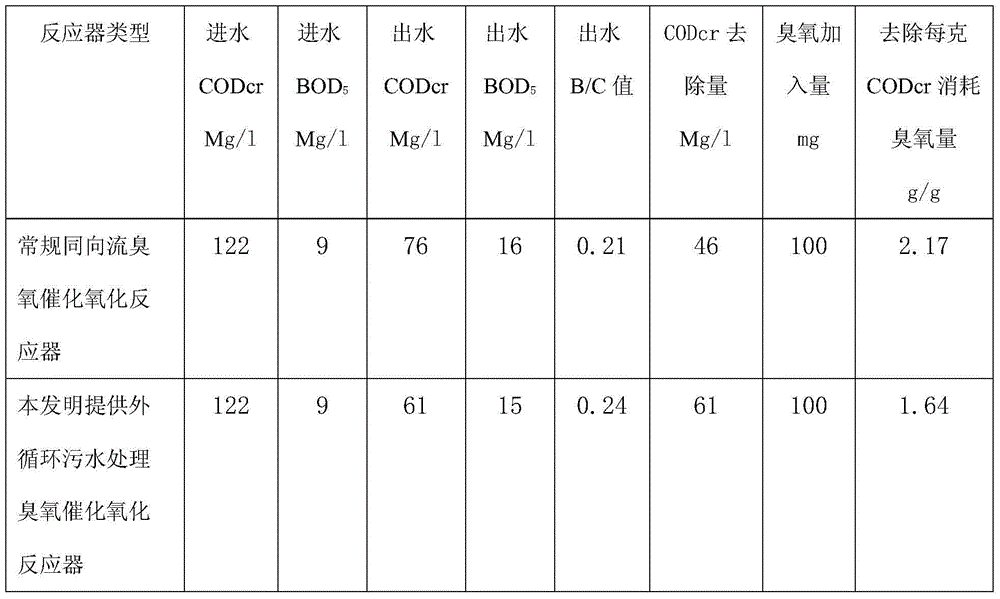

[0052] The wastewater reuse device of an oil refinery adopts a double membrane process, and the produced reverse osmosis concentrated water CODcr is between 110-130mg / l, which cannot meet the CODcr less than 50mg / l discharge standard. According to the wastewater quality and the situation of similar projects at home and abroad, the enterprise plans to adopt the ozone catalytic oxidation + biological aerated filter (BAF) process. The catalytic oxidation of ozone is to remove part of CODcr and increase the B / C value of sewage to facilitate subsequent biochemical treatment. In order to ensure the treatment effect, a field verification test was carried out. During the test, the external circulation sewage treatment ozone catalytic oxidation reactor provided by the present invention and the conventional co-current ozone catalytic oxidation reactor (sewage and ozone are all passed through the catalyst from bottom to top) (Bed layer) operation effect, the catalysts packed in the two re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com