Carbonization and activation integrated processing device and processing method thereof

A processing device and carbonization technology, which is applied in the direction of chemical instruments and methods, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of activator steam partial pressure reduction, steam reduction, etc., to achieve increased yield, stable device operation, The effect of improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

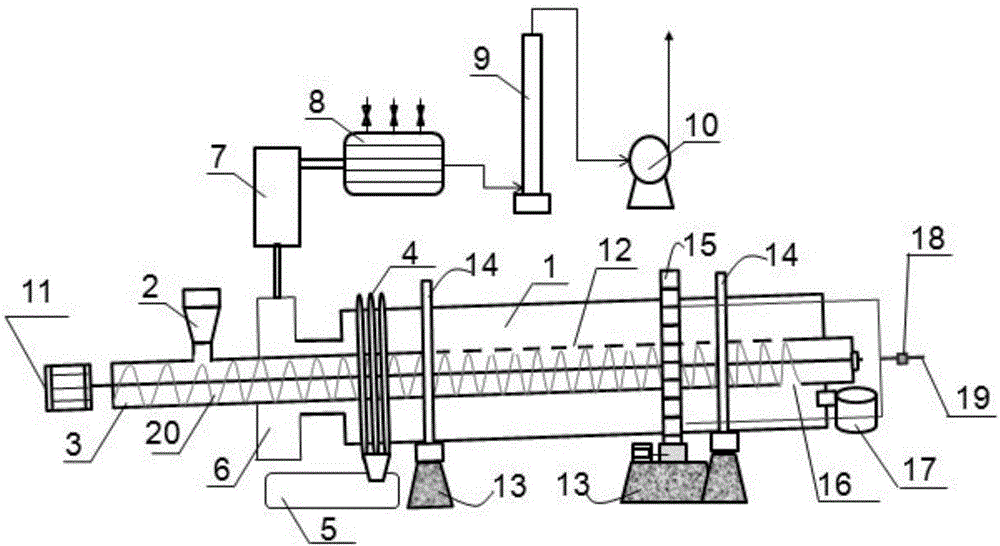

[0036] A carbonization and activation integrated processing device, such as figure 1 As shown, it includes carbonization and activation integrated converter (1), feeding device, carbonization inner tube (3), discharge cooling device, gas collection chamber (6), secondary combustion chamber (7), waste heat boiler (8), Water washing cooling tower (9), induced draft fan (10), base (13), transmission device (14), converter drive device (15), hot blast stove (17), rotary joint (18) and air intake pipe (19), of which The feeding device includes a raw material bin (2), a screw drive device (11) and a pusher screw (20), wherein the screw drive device (11) is connected to one end of the pusher screw (20), and the pusher screw (20) The other end of the carbonization inner tube (3) is inserted into the carbonization material outlet (16), and the raw material silo (2) is set above the pusher screw (20); the discharge cooling device is cooled by the discharge The coil pipe (4) is composed...

Embodiment 2

[0048] Embodiment 1 is only exemplary, and those skilled in the art should think that the cooling device can also be composed of other structures, such as a water-cooled jacket and a cooling drum; the position of the carbonized combustible gas outlet (12) can also be in the The upper side of (3) is evenly distributed, instead of being arranged in a line directly above the carbonized inner tube (3), the function of the carbonized combustible gas outlet (12) is to release the combustible gas released during the carbonization process into the activation chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com