PVC granulator

A granulator and granulation technology, applied in the direction of coating, etc., can solve the problems of uneven cutting particle size and low production efficiency, and achieve the effects of high production efficiency, precise cutting and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

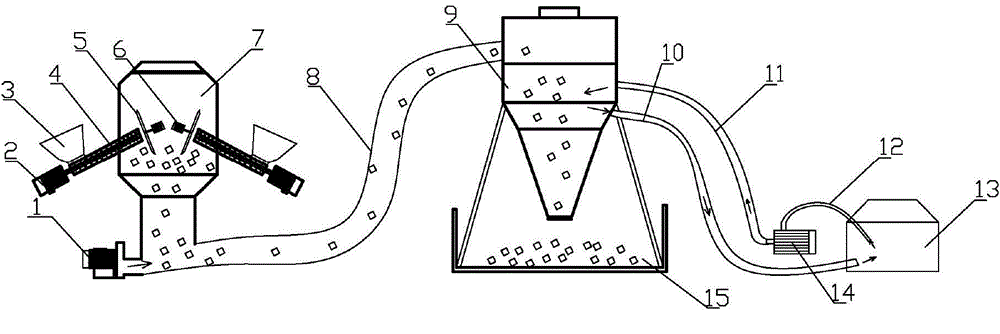

[0016] Such as figure 1 As shown, the present invention is a PVC granulator, including blower 1, motor one 2, hopper 3, screw extrusion system 4, rotary cutter 5, motor two 6, granulation tank 7, pipeline 8, cooling tank 9 , coolant return pipeline 10, coolant delivery pipeline one 11, coolant delivery pipeline two 12, coolant tank 13, water pump 14 and hopper 15, described screw extrusion system 4 stretches in the granulation tank 7, in The discharge end of screw extrusion system 4 is provided with rotary cutter 5, and described rotary cutter 5 is controlled by motor two 6, and described screw extrusion system 4 is driven by motor one 2, and described hopper 3 and screw extrusion system The upper surface of 4 is communicated and connected, the outlet of the granulation tank 7 is sealed with one end of the pipeline 8, a blower 1 is arranged at the interface between the granulation tank 7 and the pipeline 8, and the other end of the pipeline 8 is connected to the The cooling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com