Integrated shaping technology and shaping machine based on processing of plastic pins

A molding process, an integrated technology, applied to other household appliances, household appliances, household components, etc., can solve the problems of waste or delay of processing methods, quality cannot be guaranteed, processing inconsistency, etc., to improve processing efficiency, Guarantee the effect of precision control range and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

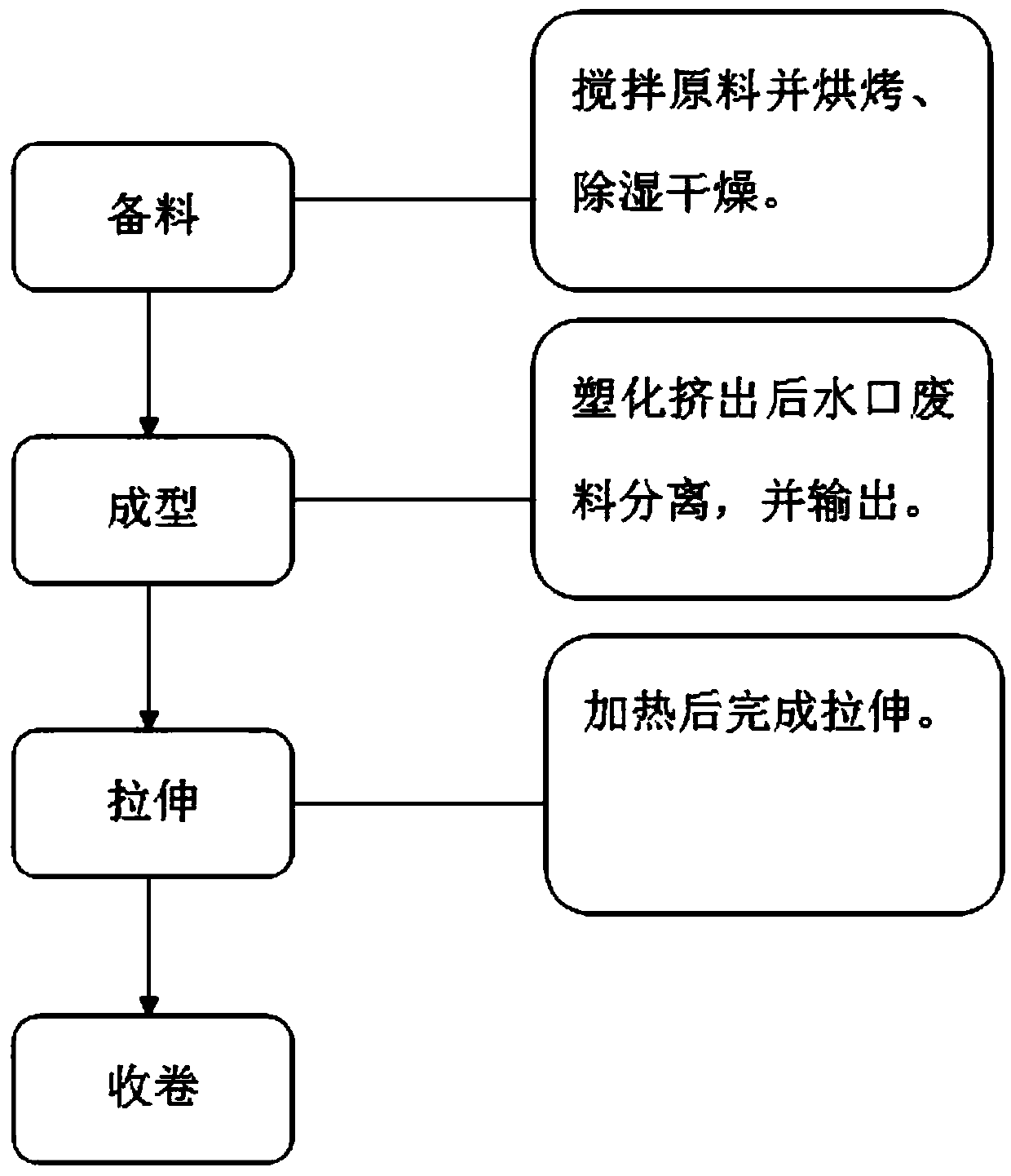

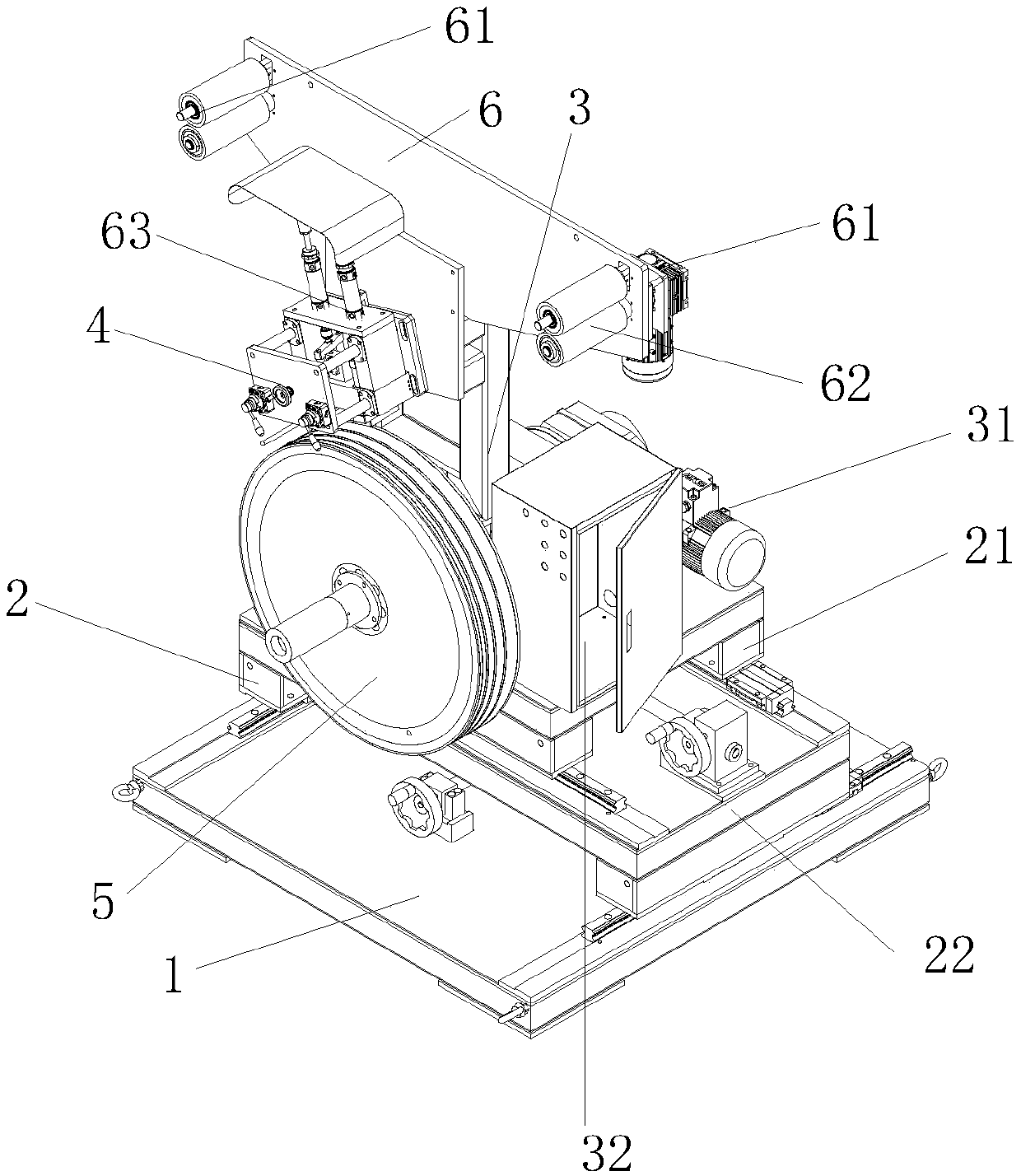

[0025] Such as Figure 1-2 As shown, the integrated molding process based on rubber needle processing provided in this embodiment includes the following steps:

[0026] (1) Set up a mixer connected to the production line, an integrated dehumidification and drying feeder, a plasticizing extruder, a molding machine and a stretching machine;

[0027] (2) Raw material preparation: set up the rubber needle raw materials and mix them evenly with a mixer, and then transport them to the integrated dehumidification and drying feeder, and the integrated dehumidification and drying feeder will obtain dry raw materials after baking, dehumidification and drying;

[0028] (3) Molding: The above-mentioned dry raw materials are transported to the plasticizing extruder, and the finished product is extruded after being plasticized by the plasticizing extruder, and the semi-finished product is obtained by separating the nozzle waste through the molding machine material, and transport the semi-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com