Copper alloy pipe straightening, lubricating, heat treatment, blanking and production preparation method

A copper alloy and straightening technology, which is applied in the direction of lubricating parts, engine lubrication, metal processing equipment, etc., can solve the problems of unproducible, long copper alloy pipes, high transportation costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

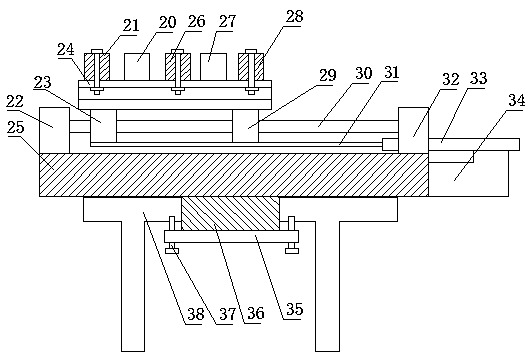

[0045] The copper alloy tube straightening, lubrication, heat treatment and blanking production and preparation method in the embodiment of the present invention adopts the guide rail bearing and motor drive mode, and the semi-finished copper alloy tube is straightened, externally lubricated, and heat treated, and then blanked to obtain a finished product The copper alloy pipe specifically comprises the following steps:

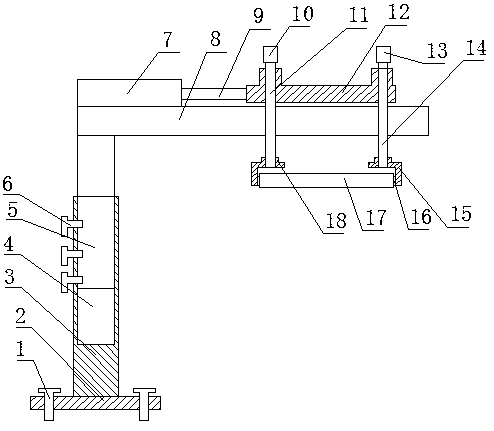

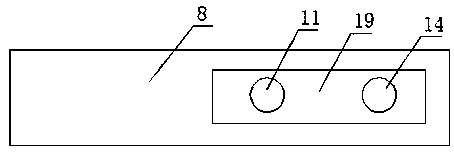

[0046] (1) After the drawn or rolled copper alloy pipe is uncoiled by the winch car, it is transported to the front end of the straightening equipment, and under the rotation of the winch car, it is transported to the straightening processing device; above the winch car, there is a copper alloy pipe The tube unwinding pushing device is used to push the raised copper alloy tube during the unwinding process of the winch car to control the feeding height of the copper alloy tube; the copper alloy tube unwinding pushing device, such as figure 1 , figure 2 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com