Separation treatment method for waste water in coal tar machining process

A technology for separation, treatment and processing of wastewater, applied in heating water/sewage treatment, multi-stage water/sewage treatment, extraction water/sewage treatment, etc. Achieving the effect of good treatment effect and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

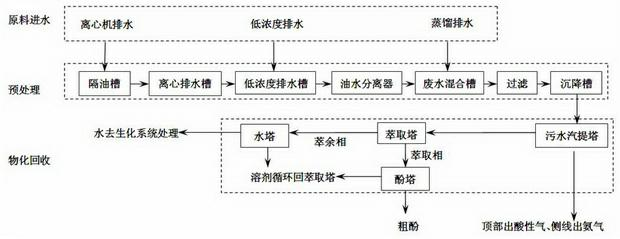

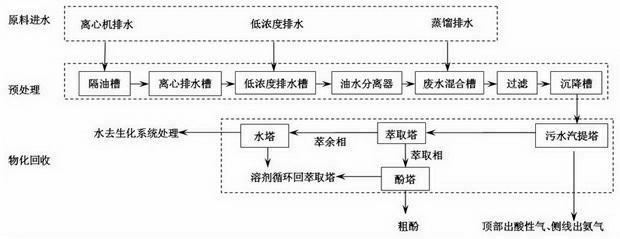

Image

Examples

Embodiment 1

[0028] like figure 1 As shown, first drain the centrifuge through the oil separation tank to separate free oil, then enter the low-concentration drainage tank to mix with low-concentration wastewater, and add dielectric to it according to the amount of 500ml 10% (wt.) polyaluminum chloride per ton of wastewater Coagulant-like coagulant for demulsification, sent to oil-water separator to remove oil, and then enters waste water mixing tank to mix with distillation and drainage water. The mixed waste water is filtered to further remove oily substances, and enters settling tank to settle to remove sediment to obtain oil-removing waste water, of which Mainly containing 0.4% ammonia, 0.8% total phenols, 0.2% sulfide total phenols and other organic matter, COD is 40000 mg L -1 ;

[0029] The above degreasing wastewater enters the sewage stripping tower, the temperature of the tower kettle is 140°C, the pressure of the tower kettle is 0.45MPa, the temperature of the tower top is 40°C...

Embodiment 2

[0034] First, drain the centrifuge and separate the free oil through the oil separation tank, then enter the low-concentration drainage tank to mix with low-concentration wastewater, and add a dielectric coagulant to it according to the amount of 500ml 10% (wt.) polyaluminum sulfate per ton of wastewater. Demulsification, send oil to water separator to remove oil, and then enter waste water mixing tank to mix with distillation and drainage water. The mixed waste water is filtered to further remove oily substances, and then enters sedimentation tank to settle to remove sediment to obtain degreasing waste water, which mainly contains 0.4% Ammonia, 0.8% total phenol, 0.2% sulfide total phenol and other organic matter, COD is 40000 mg·L -1 ;

[0035] The above degreasing wastewater enters the sewage stripping tower, the temperature of the tower kettle is 165°C, the pressure of the tower kettle is 0.65MPa, the temperature of the tower top is 80°C, the pressure of the tower top is 0...

Embodiment 3

[0040] First drain the centrifuge and separate the free oil through the oil separation tank, then enter the low-concentration drainage tank to mix with low-concentration wastewater, and add a dielectric coagulant to it according to the amount of 500ml 10% (wt.) polyaluminum chloride per ton of wastewater Carry out demulsification, send the oil-water separator to remove oil, and then enter the waste water mixing tank to mix with distillation and drainage water. The mixed waste water is filtered to further remove oily substances, and enter the settling tank to settle to remove sediment to obtain oil-removing waste water, which mainly contains 0.4 % ammonia, 0.8% total phenols, 0.2% sulfide total phenols and other organic matter, COD is 40000 mg L -1 ;

[0041] The above deoiled wastewater enters the sewage stripping tower, the temperature of the tower bottom is 155°C, the pressure of the tower bottom is 0.56MPa, the temperature of the tower top is 60°C, the pressure of the tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com