A method for directly producing electrolytic nickel with copper-nickel renewable resources

A technology for regenerating resources and electrolytic nickel, applied in the field of mineral smelting technology, can solve the problems of high cost, low comprehensive recovery rate of metals, difficult extraction of valuable metals, etc., and achieve the effects of low production cost and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

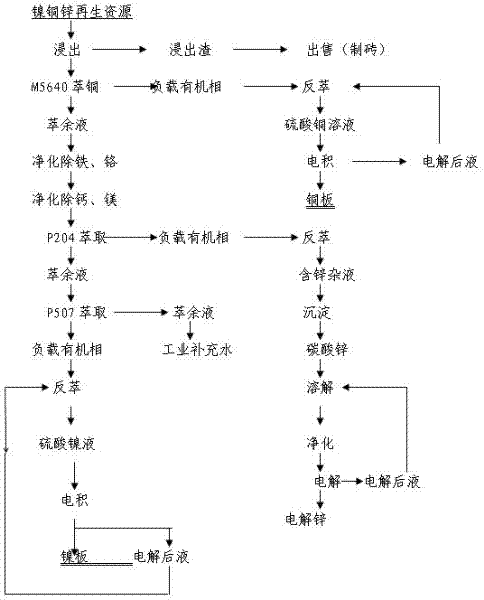

Image

Examples

Embodiment 1

[0033] A method for directly producing electrolytic nickel with copper-nickel renewable resources, first copper-nickel renewable resources containing Ni: 3.23% by mass, Cu: 1.47% Fe: 5.42%, Cr: 3.12%, Zn: 1.42%, impurities The mass percentage is 85.34%. It is pulped by ball milling, and its specific gravity is 1.3. It is pumped into a closed leaching tank, and the acidity of the pulp is adjusted with sulfuric acid to make it reach a pH of 1. It is leached under normal pressure to obtain NiSO-containing 4 、CuSO 4 The leaching slag is countercurrent washed until the pH value of the slurry is 7, and the washing slag is sold to the brick factory to make bricks. The leaching rate of Ni in the raw ore can reach 99%, and the leaching rate of Co, Zn, Cu, and Mn is >96%. The pH of the leachate is adjusted to 2.0 with alkali, and the adjusted liquid is passed through M5640 to remove Cu; The solution is back-extracted to obtain pure copper liquid, and copper plates are produced by elect...

Embodiment 2

[0071] A method of directly producing electrolytic nickel with copper-nickel renewable resources. Firstly, the copper-nickel renewable resources are ball-milled to make a slurry with a specific gravity of 1.3, pumped into a closed leaching tank, and the acidity of the pulp is adjusted with sulfuric acid to make it reach a pH of 0.5-1.0, 60-70°C, react for 30 minutes, the leaching rate of nickel is more than 99%, the leaching rate of copper is 96%-98%, and the leaching rate of zinc is 96%-97%. NiSO 4 、CuSO 4 The leached slag is countercurrent washed until the pH value of the slurry is 7, and the washed slag is sold to the brick factory to make bricks.

Embodiment 3

[0073] A method of directly producing electrolytic nickel with copper-nickel renewable resources. Firstly, the copper-nickel renewable resources are ball-milled to make a slurry with a specific gravity of 1.3, pumped into a closed leaching tank, and the acidity of the pulp is adjusted with sulfuric acid to make it reach a pH of 1.0-2.0, 60-70°C, react for 30 minutes, the leaching rate of nickel is 90%-95%, the leaching rate of copper is 85%-92%, the leaching rate of zinc is 80%-90%, and the leaching is carried out under normal pressure. NiSO 4 、CuSO 4 The leached slag is countercurrent washed until the pH value of the slurry is 7, and the washed slag is sold to the brick factory to make bricks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com