Intensified biological treatment method for high strength ammonia wastewater

A bioaugmentation and treatment method technology, which is applied in the field of bioaugmentation treatment of high ammonia nitrogen wastewater, can solve the problems of the wide application of bioaugmentation technology, the inability to effectively separate the effluent, and increase the cost of water treatment, so as to achieve rich biological species and avoid bacteria. Effects of runoff, high microbial load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

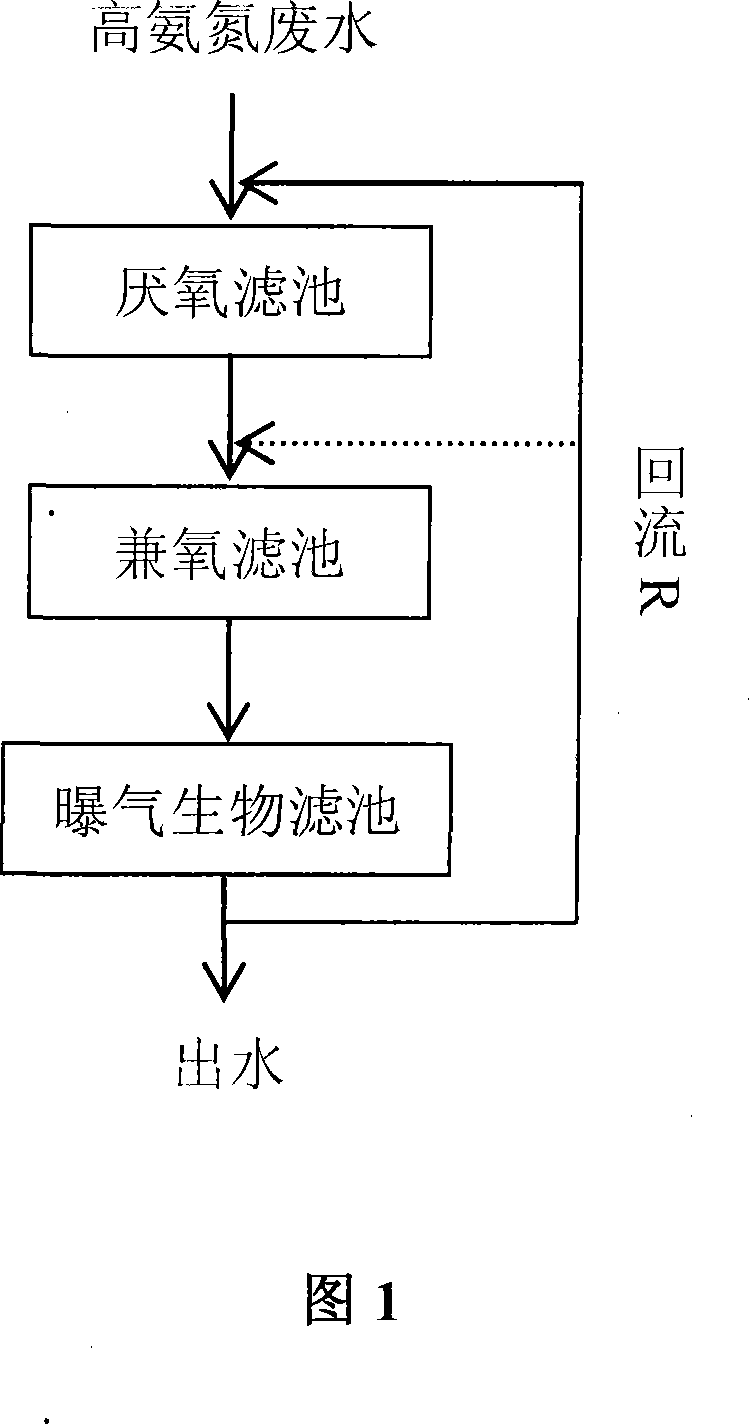

[0035] The method of the present invention is used to treat the landfill leachate, and the combined reactor of the first-level anaerobic filter + the first-level anoxic filter + the third-level biological aerated filter is adopted, and the high-efficiency composite microorganisms adopted are Biosystem B350 and B110. Raw water COD Cr The concentration is 3800-24000mg / L, NH 4 + -N concentration is 1050-2100 mg / L, the water temperature of anaerobic filter and anoxic filter is controlled at 30-35°C, the water temperature of biological aerated filter is controlled at 20-28°C, the total residence time is 96h, and the final effluent COD Cr The concentration is 260-950mg / L, NH 4 + -N concentration is 2.0-30.0mg / L. COD Cr The average removal rate reaches over 90%, NH 4 + The average removal rate of -N reaches over 99%.

Embodiment 2

[0037] The method of the present invention is used to treat the dilution water of pharmaceutical factory production waste water, and the combined reactor of two-stage anoxic filter + three-stage aerated biological filter is adopted, and the high-efficiency composite microorganisms adopted are Biosystem B350 and B500. Influent COD Cr The concentration is 950-2500mg / L, NH 4 + -N concentration is 300-450mg / L, the water temperature of anaerobic filter and anoxic filter is controlled at 30-35°C, the water temperature of biological aerated filter is controlled at 25-30°C, the total residence time is 72h, and the final effluent COD Cr The concentration is 50-150mg / L, NH 4 + -N concentration is 1.0-6.0mg / L.

Embodiment 3

[0039] The coking waste water is treated by the method of the present invention, and a combined reactor of a first-stage anaerobic filter + a first-stage anoxic filter + a two-stage aerated biological filter is used, and the high-efficiency composite microorganism adopted is Biosystem B350. Influent COD Cr The concentration is 3500-5000mg / L, NH 4 + -N concentration is 450-700mg / L, the water temperature of anaerobic filter and anoxic filter is controlled at 30-35°C, the water temperature of biological aerated filter is controlled at 20-30°C, the total residence time is 36-48h, and the final effluent COD Cr The concentration is 80-130mg / L, NH 4 + -N concentration is 0.2-1.5mg / L.

[0040] It can be seen from the above examples that the method of the present invention has a good treatment effect on different types of high ammonia nitrogen wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com