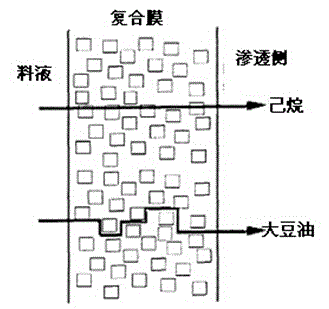

Preparation method of microporous molecular sieve filled solvent resistant composite film

A microporous molecular sieve and solvent-resistant technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of unsuitable industrial application, poor stability of mixed oil, high retention rate of soybean oil, etc., and achieve separation performance maintenance Stable, good anti-swelling performance, excellent separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

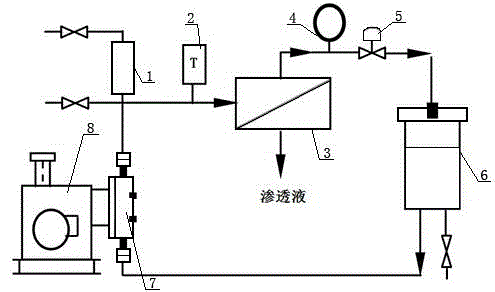

Method used

Image

Examples

Embodiment 1

[0032] Crush the ZSM-5 molecular sieve with a silicon-aluminum ratio of 300 to a particle size of less than 2 microns, add toluene to form a suspension with a mass concentration of 20% and ultrasonically disperse it for 1 hour, and then add octyltrichlorosilane with a mass concentration of 10% of ZSM-5 , and stirred at 80°C for 12 hours. After filtering, washing and drying, octyltrichlorosilane-modified ZSM-5 was obtained. Take 10 grams of fluorosilicone oil whose γ-trifluoropropyl side chain segments account for 50% of the total number of segments, dissolve it in 20 grams of methyl ethyl ketone, add 2 grams of modified ZSM-5, stir and ultrasonically disperse for 1 hour, and then add 1 1 gram of phenyltrimethoxysilane and 0.3 gram of dibutyltin diacetate were stirred evenly to obtain the casting solution, and the PVDF ultrafiltration membrane was used as the base film, and the film was scraped on the base film. After standing at room temperature for 24 hours, it was heated in...

Embodiment 2

[0037] Crush the ZSM-5 molecular sieve with a silicon-aluminum ratio of 300 to a particle size of less than 2 microns, add toluene to form a suspension with a mass concentration of 20% and ultrasonically disperse it for 1 hour, and then add octyltrimethoxy with 50% of the mass of ZSM-5 Silane, stirred at room temperature for 1 hour. After filtering, washing and drying, octyltrimethoxysilane-modified ZSM-5 was obtained. Take 10 grams of fluorosilicone oil whose γ-trifluoropropyl side chain segments account for 30% of the total number of segments, dissolve it in 90 grams of toluene, add 3 grams of modified ZSM-5, stir and ultrasonically disperse for 2 hours, then add 1 g Phenyltrimethoxysilane and 0.2 gram of dibutyltin dilaurate were stirred evenly to obtain a casting solution, and the PVDF ultrafiltration membrane was used as the base film, and the film was scraped on the base film. After standing at room temperature for 24 hours, it was heated in an oven at 120° C. for 12 ho...

Embodiment 3

[0040]The silicate-1 molecular sieve was crushed to a particle size of less than 2 microns, and toluene was added to prepare a suspension with a mass concentration of 15% for ultrasonic dispersion for 2 hours, then dodecyltrichlorosilane with a silicate mass of 20% was added, and stirred at 50 °C for 12 hours. After filtering, washing and drying, silicate-1 modified with dodecyltrichlorosilane was obtained. Dissolve 14 grams of fluorosilicone oil whose γ-trifluoropropyl side chains account for 50% of the total number of segments in 6 grams of methyl ethyl ketone, add 0.7 grams of modified silicate-1, stir and ultrasonically disperse for 5 hours, and then add 1.5 grams of octyltrimethoxysilane and 0.4 grams of dibutyltin diacetate were stirred evenly to obtain a casting solution. Use the PVDF ultrafiltration membrane as the bottom membrane, and scrape the membrane on the bottom membrane. After standing at room temperature for 24 hours, it was heated in an oven at 120 °C for 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com