Hydrophobic high-CTI polyphenylene sulfide composition as well as preparation method and application thereof

A polyphenylene sulfide, hydrophobic technology, applied in the field of engineering plastics, can solve the problems of material dimensional stability and stiffness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

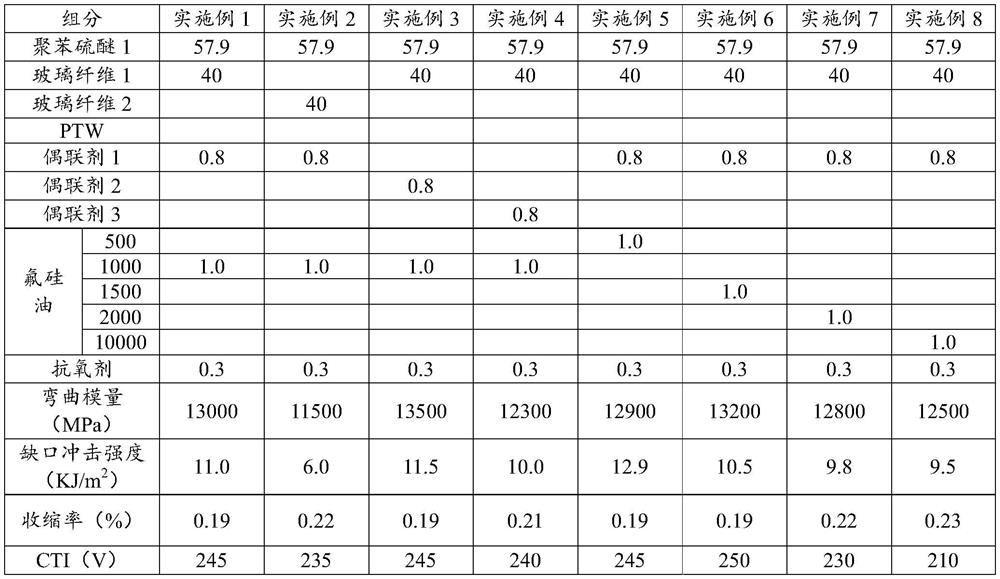

[0048] Comparing Example 1 with Example 2, it can be seen that the diameter of the glass fiber in Example 1 is in the range of 6-10mm, the diameter of the glass fiber in Example 2 is not in the above range, the flexural modulus, notch in Example 1 Impact strength, shrinkage rate, CTI are all better than embodiment 2;

[0049] Comparing Examples 1, 3, and 4, it can be seen that the coupling agent in Examples 1, 3 is one of aminosilane coupling agents and methoxysilane coupling agents, and the coupling agent in Example 4 is Titanate coupling agent, flexural modulus, notched impact strength, shrinkage, CTI of embodiment 1, 3 are all better than embodiment 4;

Embodiment 7

[0050]Comparing 1, 5-8, it can be seen that the viscosity (25°C) of the fluorosilicone oil in Examples 1, 5, and 6 is in the range of 500-1500mPa.s, and the viscosity (25°C) of the fluorosilicone oil in Example 7 is 300-9000mPa. Within the range of s, the viscosity (25°C) of the fluorosilicone oil in Example 8 is not within the range of 300-9000mPa.s, and the flexural modulus, notched impact strength, shrinkage, and CTI of Examples 1, 5, 6, and 7 are all better than those of the implementation Example 8, the flexural modulus, notched impact strength, shrinkage rate, and CTI of Examples 1, 5, and 6 are all better than Example 7;

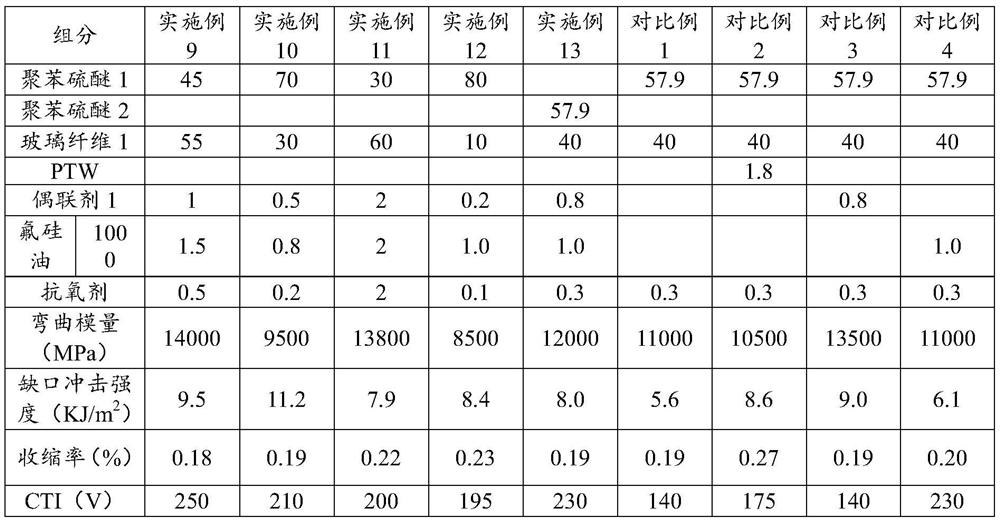

[0051] Comparing Examples 9 and 10 with Examples 11 and 12, it can be seen that Examples 9 and 10 meet the requirements of "polyphenylene sulfide 45-70 parts, glass fiber 30-55 parts, coupling agent 0.5-1 part, fluorosilicone oil 0.8- 1.5 parts and 0.2-0.5 parts of antioxidant", the notched impact strength, shrinkage rate, CTI of embodiment 9-10 are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com