Method for synthesizing low molecular weight hydroxy-terminated fluorine silicon oil

A hydroxyfluorosilicone oil, low molecular weight technology, applied in the direction of silicon organic compounds, etc., can solve the problems of difficult uniform dispersion of silica, reduced plasticity, and hardening of rubber compounds.

Inactive Publication Date: 2011-01-19

新元化学(山东)股份有限公司

View PDF4 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the surface of silica contains active Si-OH groups, and its active Si-OH groups will react with Si-OH groups or terminal Si-OH groups of silicone rubber molecules to form hydrogen bonds, resulting in physical adsorption and chemical bonding, which makes Silica is difficult to disperse evenly in the silicone rubber compound, and the mixed compound will gradually harden during storage, reduce plasticity, and gradually lose back-milling and processing performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

example 2

example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

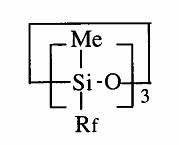

The invention relates to a method for synthesizing low molecular weight hydroxy-terminated fluorine silicon oil, which is characterized by comprising the following steps of: adding a certain amount of 3,3,3-trifluoropropylmethyl ring trisiloxane into three flasks, starting stirring, and then adding a certain amount of polar solvent, capping agent and catalyst into the flasks; slowly heating the mixture to between 50 and 80 DEG C till reflux appears, and maintaining the reaction till the reaction is complete; then cooling the mixture to room temperature, adding a certain amount of magnesium oxide and kieselguhr for filtration, and washing the filter cakes by using the same part of solvent; and transferring the filtrate to the three flasks, adjusting the temperature and pressure to evaporate the solvent, and then removing low-boiling substances to obtain a required product. The method has the advantages of simple and quick operation, economy, applicability, high yield, clarity, transparency and low viscosity of the obtained product and the like.

Description

technical field [0001] The invention relates to the preparation of low molecular weight hydroxyl-terminated fluorosilicone oil, especially the preparation of 1,3,5-tris(trifluoropropyl)-1,3,5-trimethylcyclotrisiloxane with heteropolyacid as catalyst alkane (D 3 F ) is dissolved in a polar solvent, and distilled water is used as an end-capping agent for reflux reaction to carry out a synthesis method of low-molecular-weight hydroxyl-terminated fluorosilicone oil. Background technique [0002] Low-molecular-weight hydroxyl-terminated fluorosilicone oil is a special synthetic material whose main chain contains silicon-oxygen structures, side chains contain oxygen-containing structures, and both ends are hydroxyl groups. The special chemical structure of this material not only has the characteristics of high and low temperature resistance and fuel resistance of general fluorosilicone polymers, but also has great chemical activity due to the existence of a large amount of silan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07F7/08

Inventor 张翚鹰于鹏飞解承钢

Owner 新元化学(山东)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com