High-activity hydrogen-containing fluorosilicone oil cross-linking agent and preparation method thereof

A technology of hydrofluorosilicone oil and crosslinking agent, which is applied in the field of rubber materials, can solve the problems of insufficient activity of silicon hydrogen, achieve good storage stability, high product yield, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

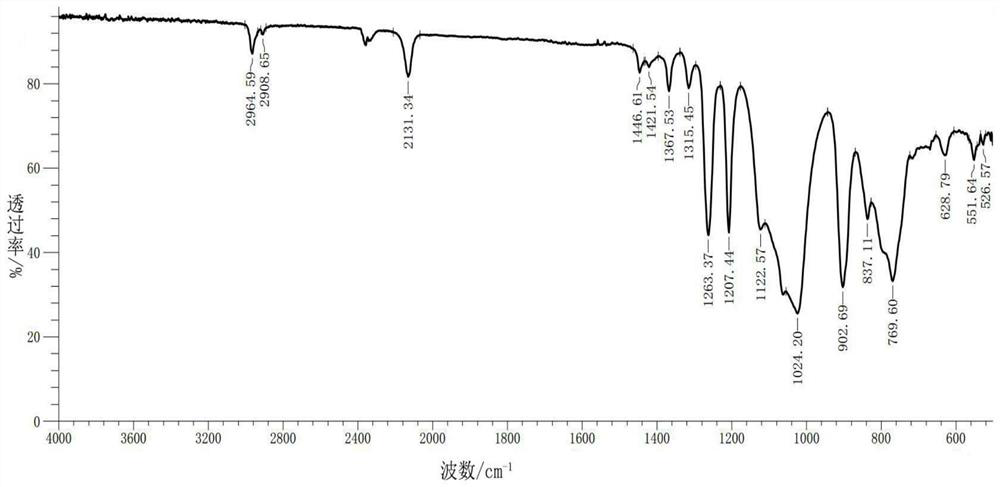

Image

Examples

Embodiment 1

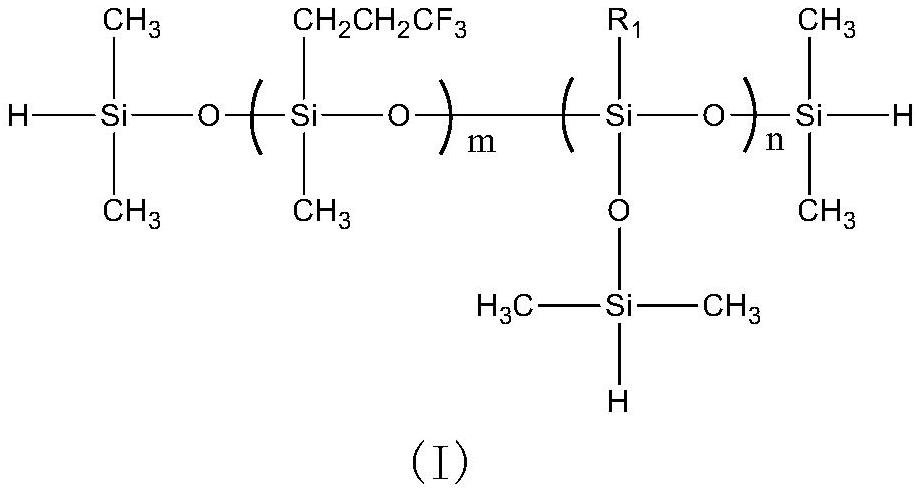

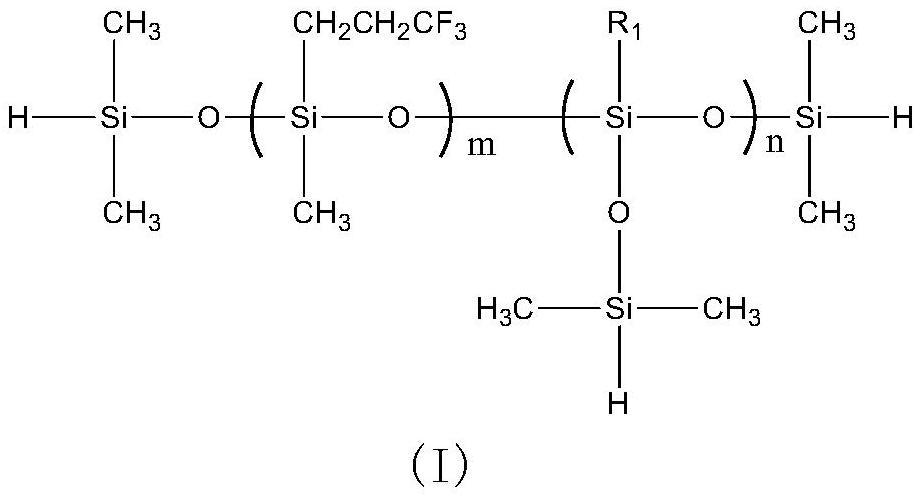

[0054] A highly active hydrofluorosilicone oil crosslinking agent with the following structure:

[0055]

[0056] The preparation steps are as follows:

[0057] (1) Preparation of methyltrimethoxysilane hydrolyzate:

[0058] Add 680g of methyltrimethoxysilane and 7g of macroporous strongly acidic styrene-based cation exchange resin to a four-necked flask equipped with a mechanical stirrer, a thermometer, a reflux tube, and a dropping funnel, start stirring and mix evenly, and heat up to 50°C. Then, 72g of distilled water was added dropwise to the system for hydrolysis and condensation reaction. During the dropping process, the system released heat, and the addition rate was adjusted so that the temperature of the kettle did not exceed 60°C. After the dropwise addition was completed, the temperature was continued to rise to 67°C for reflux reaction and maintained for 5 hours;

[0059] After the reaction is complete, lower the system to room temperature, filter the resin, co...

Embodiment 2

[0066] A highly active hydrofluorosilicone oil crosslinking agent with the following structure:

[0067]

[0068] The preparation steps are as follows:

[0069] (1) Preparation of methyltrimethoxysilane hydrolyzate:

[0070] Add 408g of methyltrimethoxysilane and 8g of macroporous strongly acidic styrene-based cation exchange resin to a four-necked flask equipped with mechanical stirring, a thermometer, a reflux tube, and a dropping funnel, start stirring and mixing evenly, and heat up to 52°C. Then add 36g of distilled water dropwise to the system for hydrolysis and condensation reaction. During the dropwise addition, the system releases heat. Adjust the rate of addition so that the temperature of the kettle does not exceed 60°C. After the dropwise addition is completed, continue to heat up to 67°C for reflux reaction and maintain for 6h;

[0071] After the reaction is complete, lower the system to room temperature, filter the resin, collect the filtrate, and remove the m...

Embodiment 3

[0078] A highly active hydrofluorosilicone oil crosslinking agent with the following structure:

[0079]

[0080] The preparation steps are as follows:

[0081] (1) Preparation of methyltrimethoxysilane hydrolyzate:

[0082] Add 1088g of methyltrimethoxysilane and 16g of macroporous strongly acidic styrene-based cation exchange resin into a four-necked flask equipped with mechanical stirring, a thermometer, a reflux tube, and a dropping funnel, start stirring and mixing evenly, and heat up to 50°C. Then add 126g of distilled water dropwise to the system for hydrolysis and condensation reaction. During the dropwise addition, the system releases heat. Adjust the rate of addition so that the temperature of the kettle does not exceed 60°C. After the dropwise addition is completed, continue to heat up to 67°C for reflux reaction and maintain for 6h;

[0083] After the reaction is complete, lower the system to room temperature, filter the resin, collect the filtrate, and remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com