Epoxy-based organic fluorosilicone oil emulsion darkening finishing agent and preparation method thereof

An organic fluorosilicone oil, epoxy-based technology, applied in the direction of fiber treatment, improved hand fiber, textile and paper making, etc., can solve the problems of affecting the hand feel of the fabric, poor washing resistance, etc. The effect of reducing the amount of reflected light and increasing the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

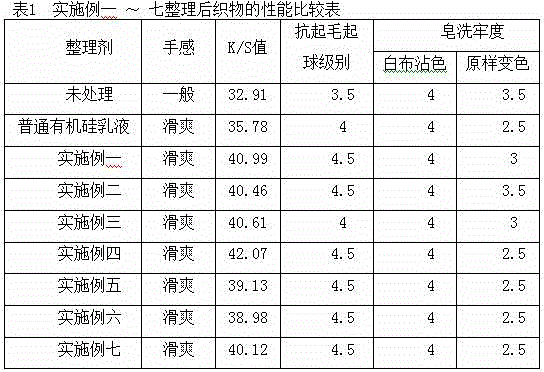

Examples

Embodiment 1

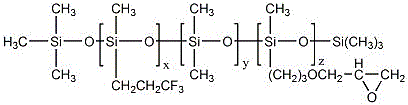

[0025] (1). Add 84g of octamethylcyclotetrasiloxane to the flask, heat up to 90°C in a water bath, and add 6g of 3-[(2,3)-glycidyloxy]propylmethyldimethoxy Mix base silane with 2g of deionized water, stir evenly, slowly drop into the above-mentioned three-necked flask, then add 0.05g of KOH, react for 3 hours, then add 10g of trifluoropropylmethylcyclotrisiloxane, Continue to react for 4 hours; add 0.1 g of hexamethyldisiloxane to the above solution to react for 1 hour, cool down to 60°C, continue to react for 20 hours, and distill the obtained liquid at a temperature of 100°C and a pressure of 2MPa for 45min, and cool to At room temperature, a uniform translucent viscous epoxy-based organic fluorosilicone oil is obtained;

[0026] (2). Prepare the epoxy-based organic fluorosilicone oil obtained in the above step (1) with a mass percentage of 30%, adjust its pH value to neutral with acetic acid solution, and when the temperature is raised to 60°C, then add the emulsifier to S...

Embodiment 2

[0028] (1). Add 82g of octamethylcyclotetrasiloxane to the flask, raise the temperature to 90°C in a water bath, and add 8g of 3-[(2,3)-glycidyloxy]propylmethyldimethoxy Mix base silane with 2g of deionized water, stir evenly, slowly drop into the above three-necked flask, then add 0.05g of KOH, react for 3 hours, then add 10g of trifluoropropylmethylcyclotrisiloxane, Continue to react for 4 hours; add 0.1 g of hexamethyldisiloxane to the above solution to react for 1 hour, cool down to 60°C, continue to react for 20 hours, and distill the obtained liquid at a temperature of 100°C and a pressure of 2MPa for 45min, and cool to At room temperature, a uniform translucent viscous epoxy-based organic fluorosilicone oil is obtained;

[0029] (2). Prepare the epoxy-based organic fluorosilicone oil obtained in the above step (1) with a mass percentage of 30%, adjust its pH value to neutral with acetic acid solution, and when the temperature is raised to 60°C, then add the emulsifier t...

Embodiment 3

[0031] (1). Add 80g of octamethylcyclotetrasiloxane to the flask, heat up to 90°C in a water bath, and add 10g of 3-[(2,3)-glycidyloxy]propylmethyldimethoxy Mix base silane with 2g of deionized water, stir evenly, slowly drop into the above-mentioned three-necked flask, then add 0.05g of KOH, react for 3 hours, then add 10g of trifluoropropylmethylcyclotrisiloxane, Continue to react for 4 hours; add 0.1 g of hexamethyldisiloxane to the above solution to react for 1 hour, cool down to 60°C, continue to react for 20 hours, and distill the obtained liquid at a temperature of 100°C and a pressure of 2MPa for 45min, and cool to At room temperature, a uniform translucent viscous epoxy-based organic fluorosilicone oil is obtained;

[0032] (2). Prepare the epoxy-based organic fluorosilicone oil obtained in the above step (1) with a mass percentage of 30%, adjust its pH value to neutral with acetic acid solution, and when the temperature is raised to 60°C, then add the emulsifier to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com