Preparation method of solvent resistant nanofiltration membrane

A nanofiltration membrane and solvent-resistant technology, which is applied in the field of solvent-resistant nanofiltration membrane preparation, can solve the problems of rapid decline in separation performance, poor separation performance of mixed oil, low flux and rejection rate, etc., and achieve stable separation performance , large industrial application potential, and the effect of simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

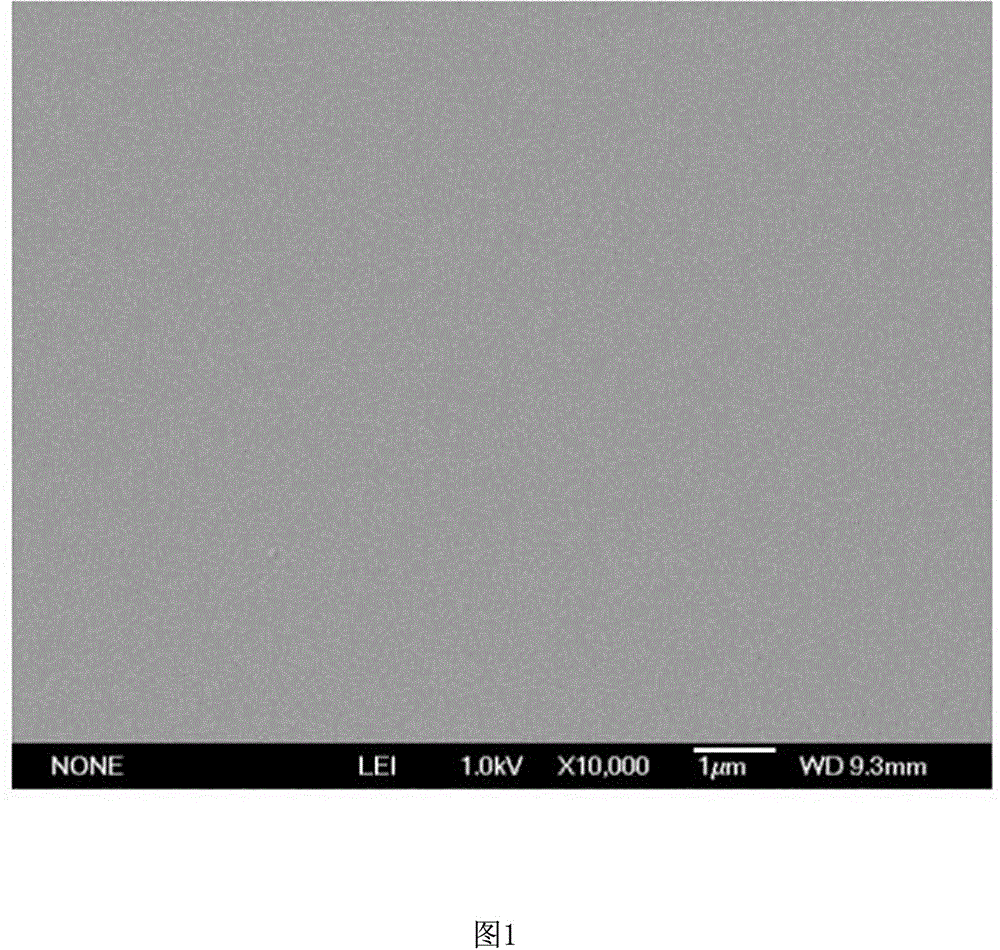

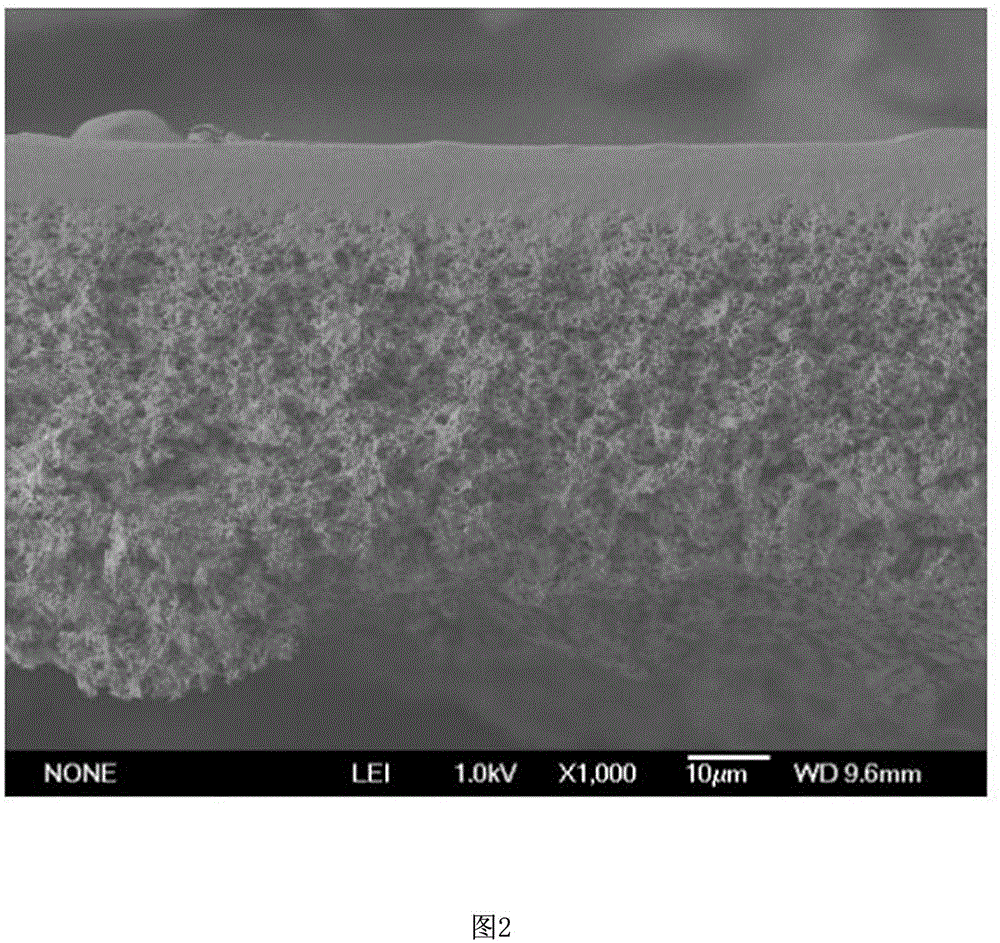

[0023] (1) Preparation of polyvinylidene fluoride (PVDF) base film: the PVDF raw material was dehydrated in an oven, and then a solution with a PVDF mass concentration of 15% was prepared with triethyl phosphate (TEP) as a solvent, and stirred at 100 °C for 24 h; After filtration and vacuum defoaming, use water as a gel bath, and use the immersion precipitation phase inversion method to scrape the film on the non-woven fabric to obtain a PVDF film, and finally fully wash off the solvent with deionized water, and dry it to obtain PVDF Ultrafiltration membrane, that is, the bottom membrane of fluorosilicone rubber solvent-resistant nanofiltration membrane.

[0024] ( 2) Prepare fluorosilicone rubber casting solution: mix fluorosilicone oil containing γ-trifluoropropyl side chains accounting for 50% of the total number of side chains, phenyltrimethoxysilane, dibutyltin diacetate and butanone, and stir well , filtered, and defoamed to obtain a fluorosilicone rubber casting soluti...

Embodiment 2

[0033] (1) Preparation of polyetherimide (PEI) base film: Dehydrate PEI raw materials in an oven, use dimethylacetamide (DMAC) as solvent and N-methylpyrrolidone as additive, and prepare PEI with a mass concentration of 15% solution, stirred for 24 h; after filtration and vacuum defoaming, water was used as the gel bath, and the film was scraped on the non-woven fabric by immersion precipitation phase inversion method to obtain the PEI film. The obtained membrane is fully washed with deionized water to remove the solvent, and dried to obtain the PEI ultrafiltration membrane, which is the bottom membrane of the fluorosilicone rubber solvent-resistant nanofiltration membrane.

[0034] (2) Preparation of fluorosilicone rubber casting solution: Mix fluorosilicone oil containing γ-trifluoropropyl side chains accounting for 50% of the total number of side chains, octyltrimethoxysilane, dibutyltin diacetate and pentanone, and stir Uniform, filtered, and defoamed to obtain the fluoros...

Embodiment 3

[0041] (1) Preparation of polyvinylidene fluoride (PVDF) base film: the method is the same as step (1) in Example 1.

[0042] (2) Preparation of fluorosilicone rubber casting solution: Mix fluorosilicone oil, hydrogen silicone oil, dibutyltin dilaurate and butanone containing γ-trifluoropropyl side chains accounting for 50% of the total number of side chains, stir well, and filter , after defoaming, the fluorosilicone rubber casting liquid is obtained, wherein the mass ratio of fluorosilicone oil:hydrogen silicone oil:dibutyltin dilaurate:butanone is 10:0.3:0.3:50.

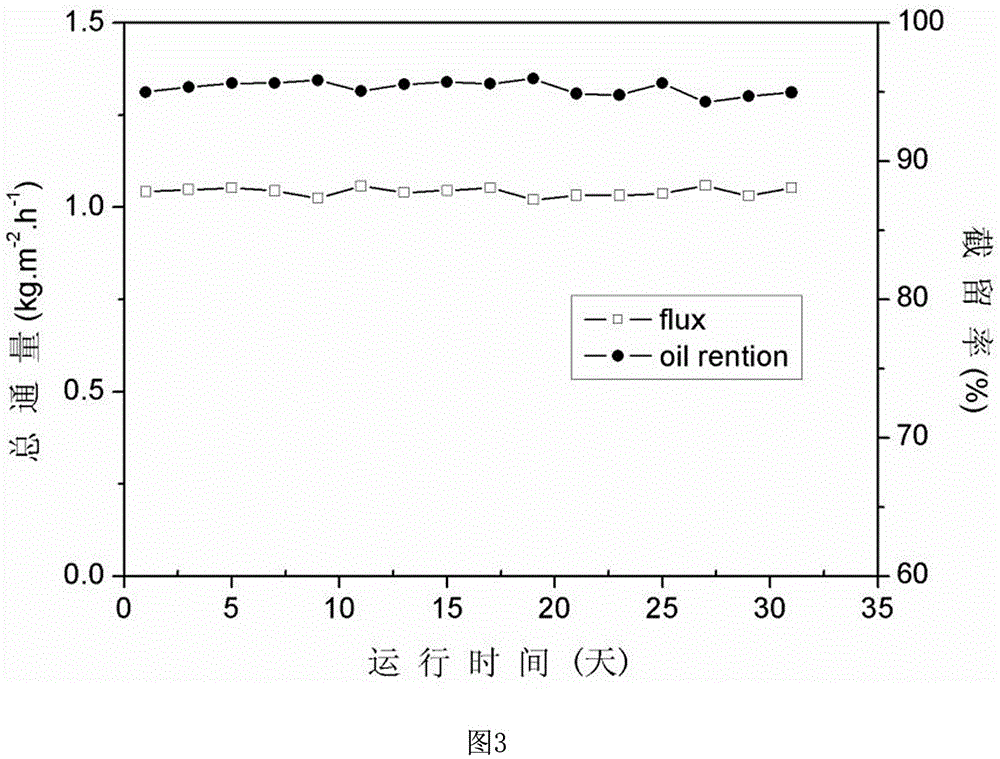

[0043] (3) Preparation of fluorosilicone rubber nanofiltration membrane: Coat the fluorosilicone rubber casting solution obtained in step (2) on the PVDF bottom membrane prepared in step (1), and place it at room temperature for 24 hours until the solvent volatilizes and initially solidifies Afterwards, heat treatment in an oven at 120°C for 36 hours to prepare a fluorosilicone rubber solvent-resistant nanofiltrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com