Fluorinated polysiloxane sealant for sealing integral fuel tank of airplane

An integral oil tank and sealant technology, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of not finding high-temperature resistant sealants, affecting the sealing performance of sealing materials, and failing to meet the temperature and resistance requirements of fuel tanks. Fuel performance requirements and other issues, to achieve good fuel resistance, improve heat resistance stability, and improve the effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

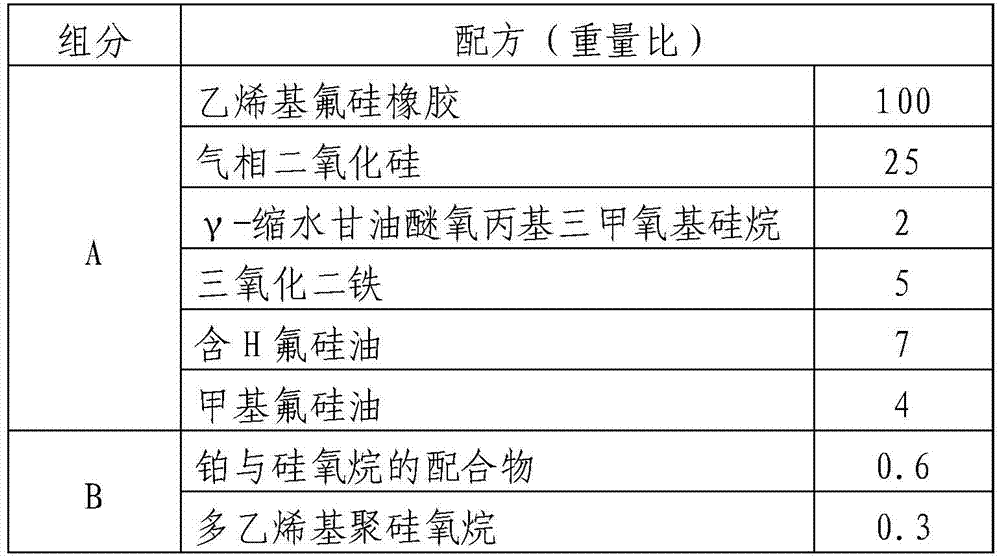

[0019] The composition formula of high temperature and fuel resistant fluorosilicone sealant is shown in Table 1:

[0020] Table 1 Formula composition of high temperature and fuel resistant fluorosilicone sealant

[0021]

[0022] The synthesis steps of the complex of platinum and siloxane are as follows: Platinum (0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane and methyl fluorosilicone oil according to 1: 100 mixed and stirred for 1 hour to obtain a dilution of the complex of platinum and siloxane.

[0023] The test piece prepared by using this compound has a tensile strength of 3.81MPa, an elongation at break of 308%, and a 180° peel strength of 3.12kN / m; after heat-resistant treatment at 250°C*100h, its The appearance has not changed, but the mechanical properties have declined slightly. The tensile strength is 3.16MPa, and the elongation at break is 281%. Under the same conditions, the polysulfide sample has been severely pulverized, and its mechanical properties afte...

Embodiment 2

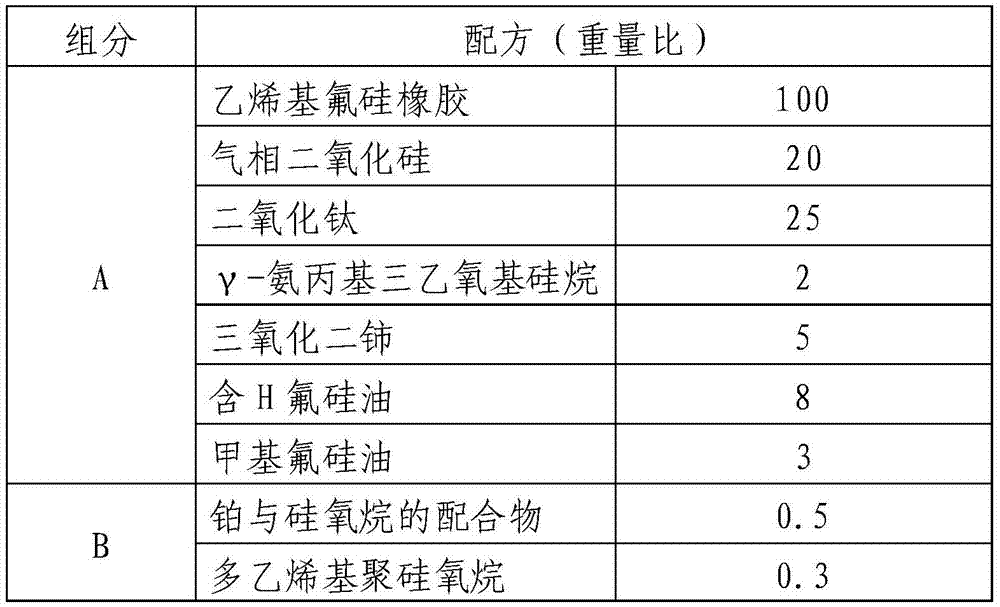

[0025] The composition formula of high temperature and fuel resistant fluorosilicone sealant is shown in Table 2:

[0026] Table 2 The composition of the high temperature and fuel resistant fluorosilicone sealant

[0027]

[0028] The mixed coupling agent is the product obtained after mixing γ-glycidyl etheroxypropyltrimethoxysilane and γ-aminopropyltriethoxysilane and reacting at 60℃~80℃ for 1h~3h, mixing before reaction The coupling agent is γ-glycidyl etheroxypropyltrimethoxysilane and γ-aminopropyltriethoxysilane with a mass ratio of 1:1; the synthesis steps of the complex of platinum and siloxane are as follows: platinum (0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane and methyl fluorosilicone oil were mixed at a ratio of 1:100 and stirred for 1 hour to obtain a complex of platinum and siloxane Diluent.

[0029] The test piece prepared by using this compound formula has a tensile strength of 3.78MPa, an elongation at break of 316%, and a 180°peel strength of 3.65kN / ...

Embodiment 3

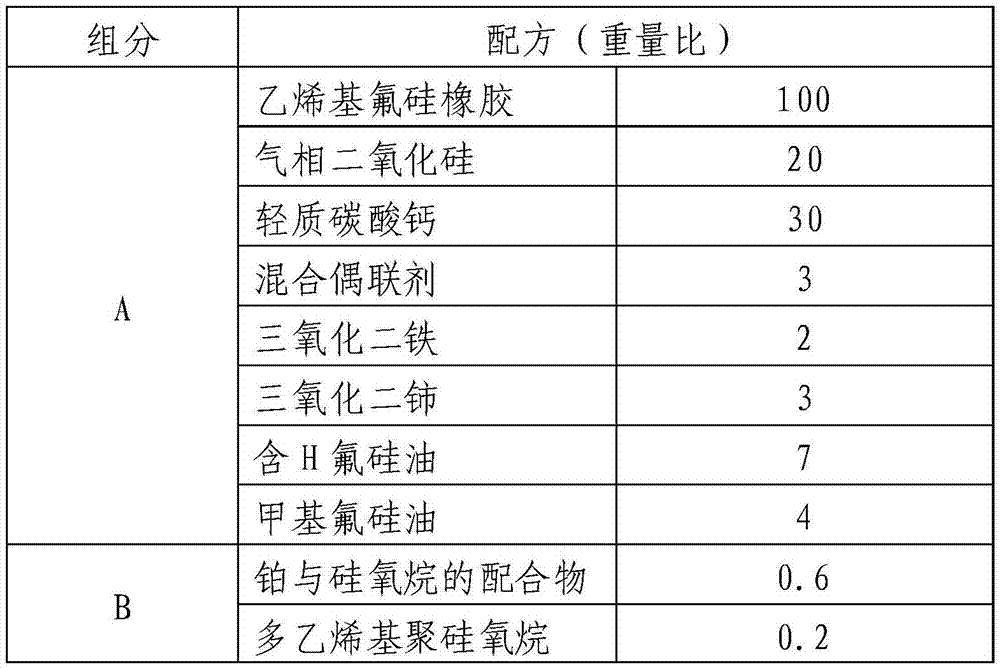

[0031] The composition formula of high temperature and fuel resistant fluorosilicone sealant is shown in Table 3:

[0032] Table 3 Formula composition of high temperature and fuel resistant fluorosilicone sealant

[0033]

[0034] The synthesis steps of the complex of platinum and siloxane are as follows: Platinum (0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane and methyl fluorosilicone oil according to 1: 100 mixed and stirred for 1 hour to obtain a dilution of the complex of platinum and siloxane.

[0035] The test piece prepared by using this compound has a tensile strength of 3.69MPa, an elongation at break of 321%, and a 180° peel strength of 3.58kN / m; after heat-resistant treatment at 250°C*100h, its The appearance has not changed, but the mechanical properties have declined slightly. The tensile strength is 3.02MPa, and the elongation at break is 299%. Under the same conditions, the polysulfide sample has been severely pulverized, and its mechanical properties afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| 180°peel strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com