Long-chain alkyl phenyl fluorosilicone oil and preparation method thereof

A technology of long-chain alkylbenzene and fluorosilicone oil, which is applied in the field of synthesis of long-chain alkylphenyl fluorosilicone oil, which can solve the problem of poor compatibility between fluorosilicone lubricating oil and synthetic oil or mineral oil, and thermal performance that cannot meet the scope of use. , Difficult to mix and use, etc., to achieve the effect of low cost, easy control, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

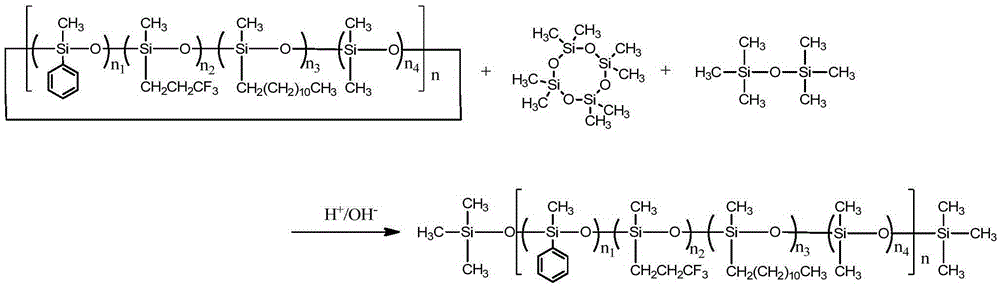

[0036] in N 2 Under protection, in a 100ml dry three-necked flask equipped with a reflux condensing device, a thermometer, and a magnetic stirrer, add dodecylphenyltrifluoropropyl co-modified siloxane mixed rings (self-made, the quality of fluorine Fraction is 20%, phenyl mass fraction is 8%, dodecyl mass fraction is 5%) 40g, octamethylcyclotetrasiloxane 20g, hexamethyldisiloxane 1.93g, 98% concentrated sulfuric acid 2.4 g, react at 25°C for 24 hours, after the reaction, add 4.15g of sodium bicarbonate to fully stir and neutralize, remove the solid salt in it by high-speed centrifugation, and remove it by distillation at a vacuum degree of -0.096Mpa and a system temperature of 200°C for 2 hours Among them, unreacted raw materials and low boilers can be used to obtain dodecylphenyl fluorosilicone oil.

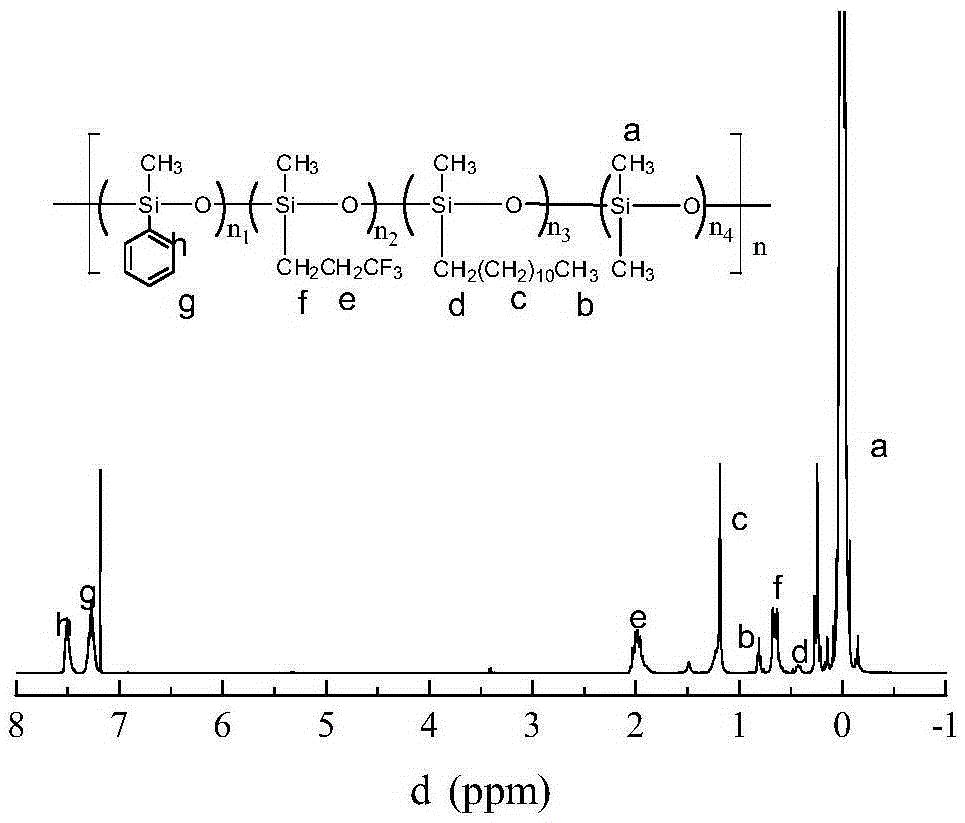

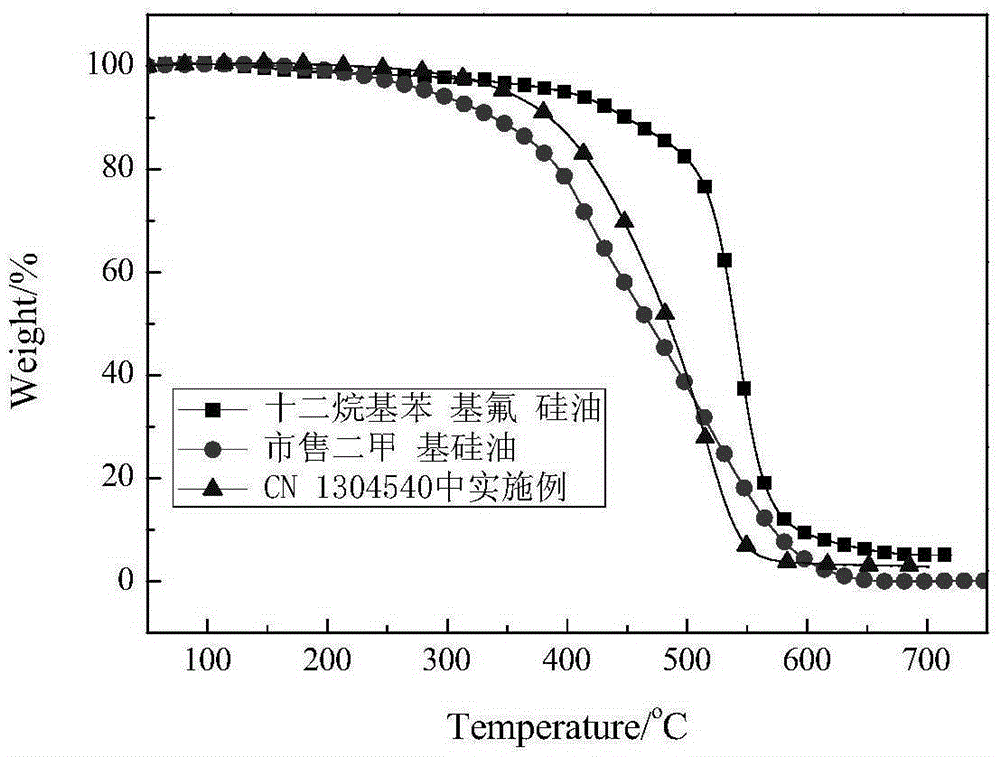

[0037] The dodecylphenyl fluorosilicone oil prepared in this implementation is a clear and transparent liquid with a molecular weight of 5300g / mol, wherein the fluorine content...

Embodiment 2

[0040] in N 2 Under protection, in a 100ml dry three-necked flask equipped with a reflux condensing device, a thermometer, and a magnetic stirrer, add dodecylphenyltrifluoropropyl co-modified siloxane mixed rings (self-made, the quality of fluorine Fraction is 10%, phenyl mass fraction is 15%, dodecyl mass fraction is 5%) 40g, octamethylcyclotetrasiloxane 20g, hexamethyldisiloxane 0.32g, tetramethylhydroxide Ammonium 0.012g, react at 70°C for 12 hours, heat up to 170°C for 30 minutes after the reaction, decompose tetramethylammonium hydroxide, and remove it by distillation at a vacuum degree of -0.096Mpa and a system temperature of 200°C for 2 hours Dodecylphenyl fluorosilicone oil can be obtained from unreacted raw materials and low boilers.

[0041] The dodecylphenyl fluorosilicone oil prepared in this implementation is a clear and transparent liquid with a molecular weight of 35000g / mol, wherein the fluorine content is 5.86%, the phenyl content is 9.68%, and the dodecyl co...

Embodiment 3

[0044] in N 2 Under protection, in a 100ml dry three-necked flask equipped with a reflux condensing device, a thermometer, and a magnetic stirrer, add dodecylphenyltrifluoropropyl co-modified siloxane mixed rings (self-made, the quality of fluorine Fraction is 20%, phenyl mass fraction is 8%, dodecyl mass fraction is 5%) 40g, octamethylcyclotetrasiloxane 20g, tetramethyldiethylsiloxane 0.14g, tetramethyl Ammonium hydroxide 0.006g, react at 70°C for 12 hours, heat up to 170°C for 30 minutes after the reaction, decompose tetramethylammonium hydroxide, and distill for 2 hours at a vacuum degree of -0.096Mpa and a system temperature of 200°C Dodecylphenyl fluorosilicone oil can be obtained by removing unreacted raw materials and low boilers.

[0045] The dodecylphenyl fluorosilicone oil prepared in this implementation is a clear and transparent liquid with a molecular weight of 83000g / mol, wherein the fluorine content is 13.12%, the phenyl content is 4.87%, and the dodecyl conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com