Preparation method of bionic super-lubricating composite anti-corrosion coating with self-restoration function

An anti-corrosion coating and super-lubricating technology, applied in coatings, surface reaction electrolytic coatings, metal material coating processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

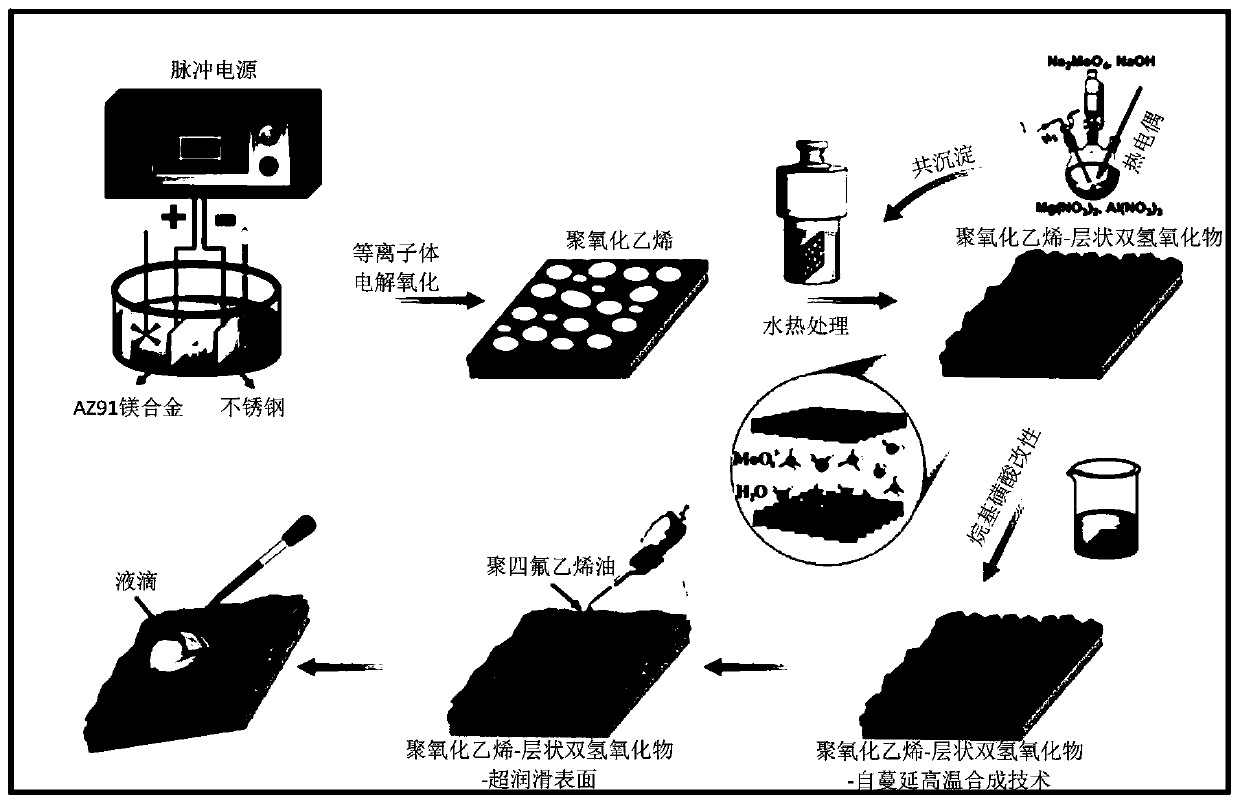

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of micro-arc oxidation (MAO) film

[0031] Raw material components: electrolyte alkaline silicate system, composed of 15g / L Na 2 SiO 3 and 10g / L of KOH composition.

[0032] Preparation process: A double-pulse micro-arc oxidation power supply is used to perform micro-arc oxidation treatment on the magnesium alloy sample. The magnesium alloy sample is used as the anode, and the stainless steel plate is used as the cathode. The constant voltage mode is adopted. The power supply parameters are: voltage 300V, frequency 600Hz, duty cycle The ratio is 5%, and the processing time is 10 minutes. During the micro-arc oxidation process, the cooling water is continuously circulated and stirred continuously to keep the temperature of the electrolyte below 30°C.

[0033] (2)MoO 4 2- Preparation of Intercalated Layered Double Hydroxide (LDH) Membranes

[0034] Raw material composition: micro-arc oxidation pretreated magnesium alloy sample, MoO 4 2- Intercalate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com