Negative pole slurry of lithium ion battery, rapid preparation method thereof and negative pole piece of lithium ion battery

A lithium-ion battery and negative electrode slurry technology, which is applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of high energy consumption of equipment, unfavorable continuous operation of production efficiency, long mixing time, etc., to reduce equipment Effects of energy consumption, shortening wetting and dispersing time, and reducing mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

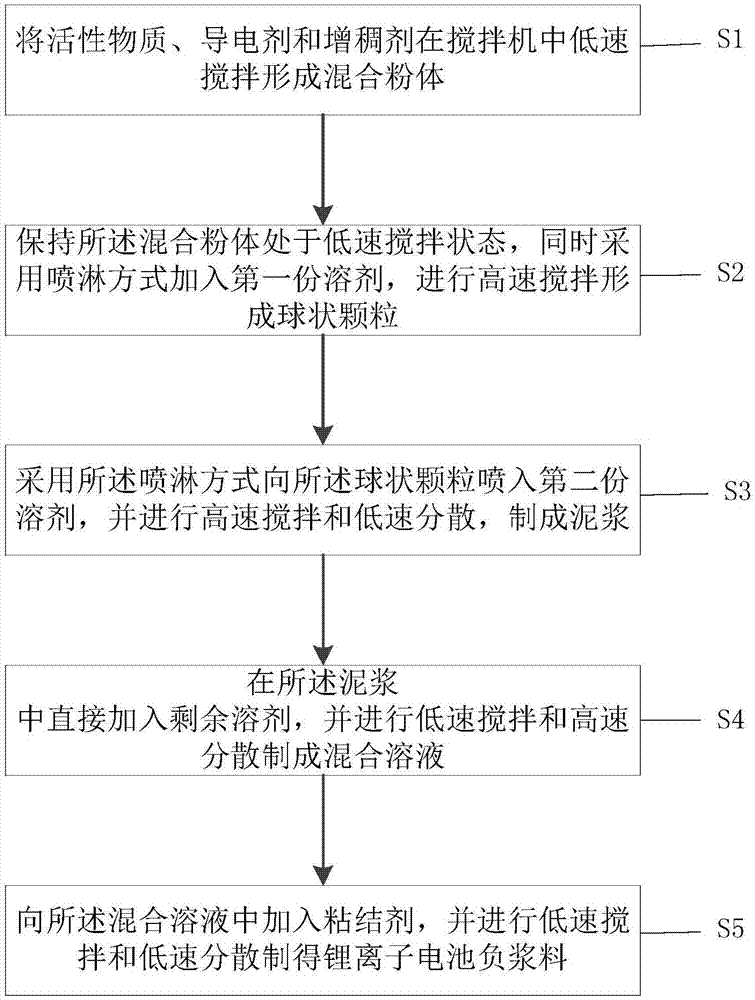

[0026] Such as figure 1 Shown, this preparation method comprises the following steps:

[0027] S1. Stir the active material, conductive agent and thickener in a mixer at a low speed to form a mixed powder.

[0028] Specifically, put 94-95 parts by weight of the active material, 1-2 parts by weight of the conductive agent and 1.5 parts by weight of the thickener into the mixing barrel of the mixer, select a lower stirring speed, To prevent the powder from splashing out, choose to stir at a stirring speed of 5 rpm / min to 25 rpm / min for 10 minutes to form a mixed powder. Further, the stirring speed is preferably 15 rpm / min to 20 rpm / min.

[0029] Wherein, the active material can be a negative electrode graphite material, and the negative electrode graphite material used can be one or more of artificial graphite, natural graphite, and mesocarbon microspheres; the conductive agent can be conductive carbon black, conductive graphite, carbon fiber One or more of them; the thickener...

Embodiment 1

[0044] Each of the following sets represents 100g;

[0045] Take 1.0 parts of conductive carbon black, 95.0 parts of artificial graphite, and 1.5 parts of thickener, and add them to a mixer and mix them uniformly for 10 minutes at a speed of 20 rpm to form a powder; under slow stirring, add 10 parts of deionized water from the feeding port to Stir at a stirring speed of 40rpm / min for 10 minutes; spray and add 43 parts of deionized water from the feeding port under slow stirring, stir at a stirring speed of 40rpm / min and a dispersion speed of 1000rpm / min for 10 minutes; directly add 47 parts of deionized water After water, stir for 10 minutes at a stirring speed of 15rpm / min and a dispersion speed of 2500rpm / min; add styrene-butadiene rubber solution containing 2.5 parts of solids, and stir for 10 minutes at a stirring speed of 15rpm / min and a dispersion speed of 300rpm / min Obtain negative electrode slurry.

Embodiment 2

[0047] Each of the following sets represents 100g;

[0048] Take 1.5 parts of conductive carbon black, 94.5 parts of artificial graphite, and 1.5 parts of thickener, add them into the mixer and mix them uniformly for 10 minutes at a speed of 20 rpm to form a powder; under slow stirring, add 12 parts of deionized water from the feeding port to Stir at a stirring speed of 45rpm / min for 15 minutes; spray and add 40 parts of deionized water from the feeding port under slow stirring, stir at a stirring speed of 40rpm / min and a dispersion speed of 1000rpm / min for 15 minutes; directly add 48 parts of deionized water After water, stir for 10 minutes at a stirring speed of 15rpm / min and a dispersion speed of 2500rpm / min; add styrene-butadiene rubber solution containing 2.5 parts of solids, and stir for 10 minutes at a stirring speed of 15rpm / min and a dispersion speed of 300rpm / min Obtain negative electrode slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com