Fluorine modified aspartic polyurea coating and preparation method thereof

A fluorine modification and coating technology, applied in the field of fluorine modified aspartame polyurea coating and its preparation, can solve the problems of insufficient aging resistance, high VOC emission, low water contact angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

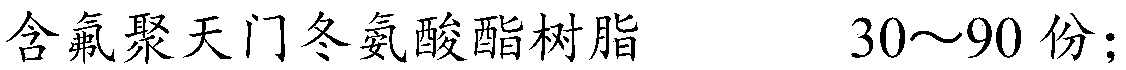

[0046] A kind of fluorine-modified aspartic polyurea paint, specifically comprises following component:

[0047] A component

[0048]

[0049] B component:

[0050] 20 parts by weight of hexamethylene diisocyanate trimer;

[0051] 80 parts by weight of isophorone diisocyanate dimer;

[0052] B component NCO% is 10.2%.

[0053] Mix components A and B according to the ratio of 100:56 and apply evenly.

[0054] At the same time, the fluorine-containing polyaspartic acid ester resin used therein, the resin raw material required for its synthesis can include the following components:

[0055]

[0056] Fumaryl chloride, trifluoroethanol, p-hydroxyphenyl ether, and pyridine were mixed in a 1000ml four-necked flask and heated to 70°C for 3 hours. The product is washed with water to remove salt, and finally purified by rectification to obtain fumaric acid-1,1'-di(2,2,2-trifluoroethyl) ester. Get 353g fumaric acid-1,1'-bis(2,2,2-trifluoroethyl) ester and 110g of 4,4'-diamino...

Embodiment 2

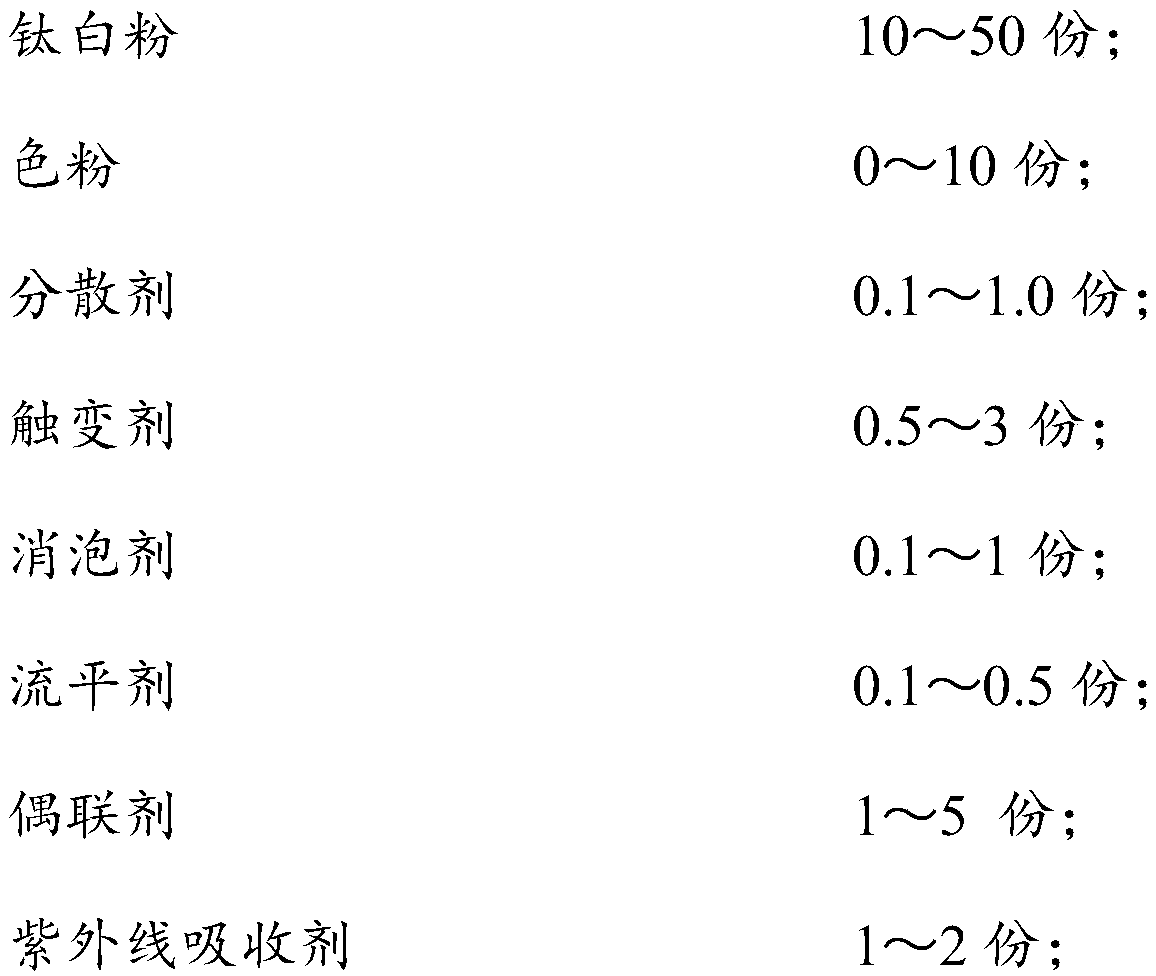

[0059] A kind of fluorine-modified aspartic polyurea coating, this coating comprises following component:

[0060] A component

[0061]

[0062] B component:

[0063] 100 parts by weight of hexamethylene diisocyanate trimer;

[0064] B component NCO% is 23%.

[0065] Mix components A and B according to the ratio of 5:1 and apply evenly.

[0066] At the same time, the raw material formula required for the synthesis of the fluorine-containing polyaspartate resin used is as follows:

[0067]

[0068] Fumaryl chloride, trifluoroethanol, p-hydroxyphenyl ether, and pyridine were mixed in a 1000ml four-neck flask and heated to 60°C for 3 hours. The product is washed with water to remove salt, and finally purified by rectification to obtain fumaric acid-1,1'-di(2,2,2-trifluoroethyl) ester. Take 353g of fumaric acid-1,1'-di(2,2,2-trifluoroethyl) ester with 4,4'-diaminodicyclohexylmethane and 3,3'-dimethyl-4 , 4'-diaminodicyclohexylmethane was mixed in a 500ml four-necked flas...

Embodiment 3

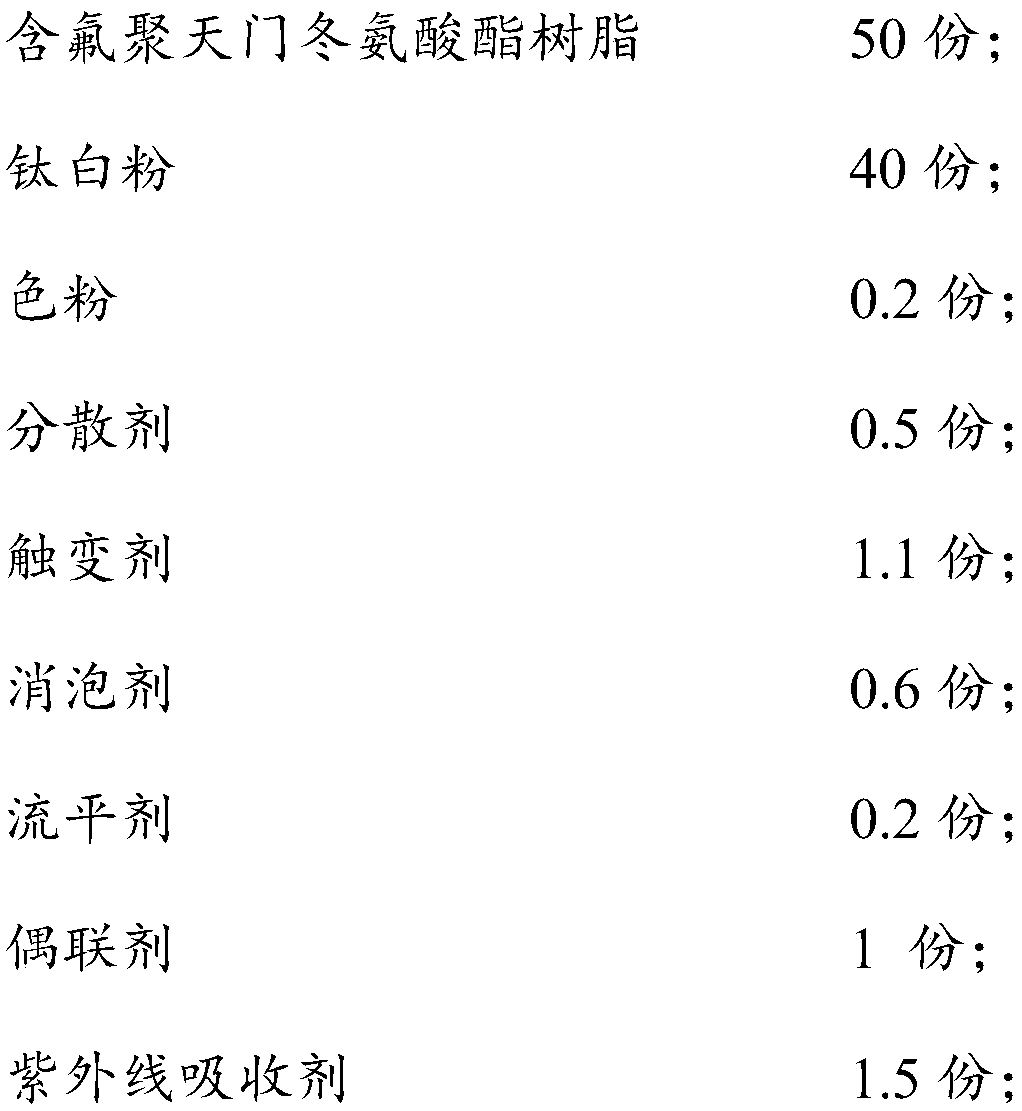

[0070] A kind of fluorine-modified aspartic polyurea coating, described coating comprises following component

[0071] A component

[0072]

[0073]

[0074] B component:

[0075] 100 parts by weight of hexamethylene diisocyanate trimer;

[0076] B component NCO% is 23.5%.

[0077] Mix components A and B according to the ratio of 1:0.31 and apply evenly.

[0078] Meanwhile, the fluorine-containing polyaspartic acid ester resin used, its synthetic raw material formulation components are as follows:

[0079]

[0080] Fumaryl chloride, trifluoroethanol, p-hydroxyphenyl ether, and triethylamine were mixed in a 1000ml four-neck flask and heated to 50°C for 4 hours. The product is washed with water to remove salt, and finally purified by rectification to obtain fumaric acid-1,1'-di(2,2,2-trifluoroethyl) ester. Take 353g of fumaric acid-1,1'-bis(2,2,2-trifluoroethyl) ester and isophorone diamine and mix them in a 500ml four-necked flask, and incubate at 90°C for 30 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com