Modified asphalt waterproof coiled material with self-adhesive layer and preparation method of modified asphalt waterproof coiled material

A technology of modified asphalt and waterproof membrane, which is applied in the direction of asphalt coatings, coatings, adhesives, etc., can solve the problems of short service life and poor mechanical properties, and achieve the effect of increasing the effective life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

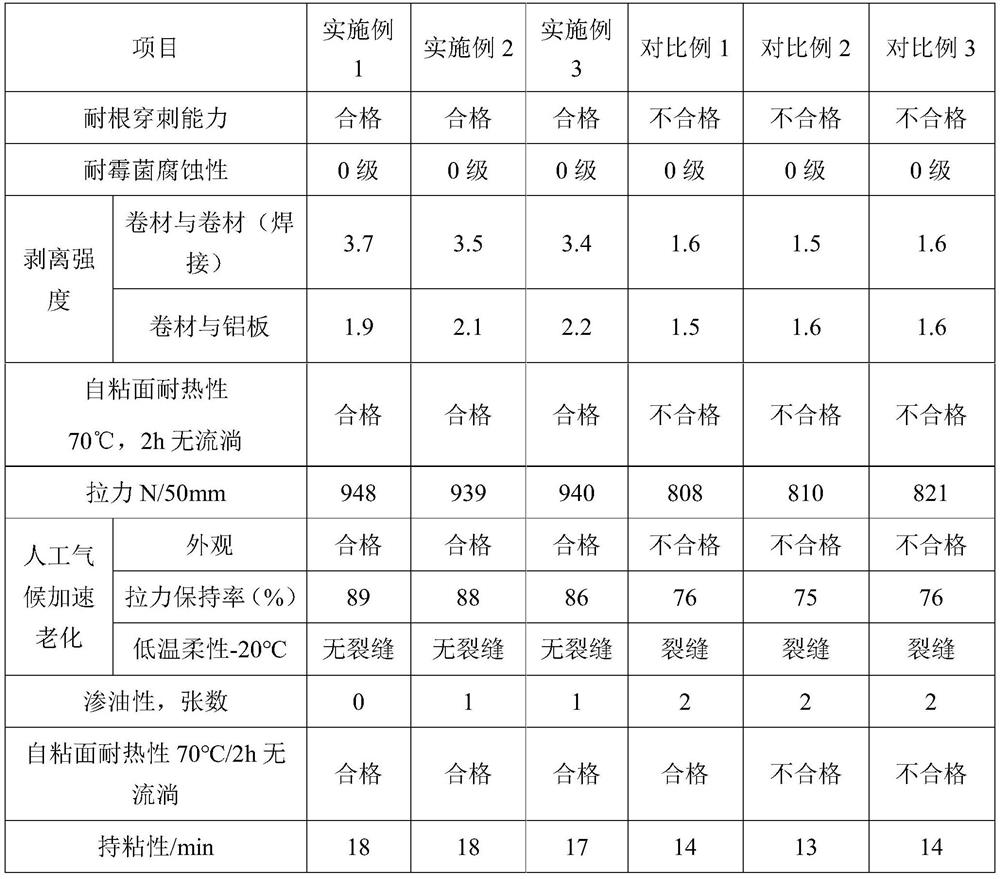

Examples

Embodiment 1

[0034] S1, preparation of modified asphalt coating material:

[0035] formula:

[0036] raw material name Specification number of copies asphalt 90# 30 asphalt 200# 27 SBS 5.2 rubber activator 60 mesh 7.3 PP 1.5 talcum powder 325 mesh 28 root inhibitor Germany LANXESS B5 0.7 fungicide Clariant 0IT45 CLARIANT 0.3

[0037] Synthesis:

[0038] 1) Add the measured 90# and 200# asphalt into the reaction kettle, heat to 120°C and stir evenly, keep the speed at 60r / min, and stir for 30min;

[0039] 2) Add the measured SBS and PP at 150°C, adjust the speed to 80r / min, and gradually raise the temperature to 185°C;

[0040] 3) Add the rubber activator four times at 190°C, adjust the speed to 90r / min, and stir for 2h;

[0041] 4) Turn on the colloid mill for grinding, cycle 4 times, and grind for 1 hour;

[0042] 5) Add root inhibitor and continue to stir for 30 minutes;

[0043] 6) Add talcum powder in b...

Embodiment 2

[0052] S1, preparation of modified asphalt coating material:

[0053] formula:

[0054] raw material name Specification number of copies asphalt 90# 40 asphalt 200# 25 SBS 5 rubber activator 60 mesh 6 PP 2 talcum powder 325 mesh 30 root inhibitor Germany LANXESS B5 0.5 fungicide Clariant 0IT45 CLARIANT 0.2

[0055] Synthesis:

[0056] 1) Add the measured 90# and 200# asphalt into the reaction kettle, heat to 110°C and stir evenly, keep the speed at 60r / min, and stir for 30min;

[0057] 2) Add the measured SBS and PP at 150°C, adjust the speed to 80r / min, and gradually raise the temperature to 185°C;

[0058] 3) Add the rubber activator four times at 190°C, adjust the speed to 90r / min, and stir for 2h;

[0059] 4) Turn on the colloid mill for grinding, cycle 3 times, and the grinding time is 1.5h;

[0060] 5) Add root inhibitor and continue to stir for 30 minutes;

[0061] 6) Add talc powder in ...

Embodiment 3

[0070] S1, preparation of modified asphalt coating material:

[0071] formula:

[0072] raw material name Specification number of copies asphalt 90# 35 asphalt 200# 30 SBS 6 rubber activator 60 mesh 8 PP 1 talcum powder 325 mesh 25 root inhibitor Germany LANXESS B5 1 fungicide Clariant 0IT45 CLARIANT 0.4

[0073] Synthesis:

[0074] 1) Add the measured 90# and 200# asphalt into the reaction kettle, heat to 110°C and stir evenly, keep the speed at 50r / min, and stir for 40min;

[0075] 2) Add the measured SBS and PP at 120°C, adjust the speed to 75r / min, and gradually raise the temperature to 185°C;

[0076] 3) Add the rubber activator four times at 190°C, adjust the speed to 90r / min, and stir for 2h;

[0077] 4) Turn on the colloid mill for grinding, cycle 3 times, and the grinding time is 1.5h;

[0078] 5) Add root inhibitor and continue to stir for 30 minutes;

[0079] 6) Add talcum powder in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com