Seawater-based fracturing fluid synergist and fracturing fluid and preparation method

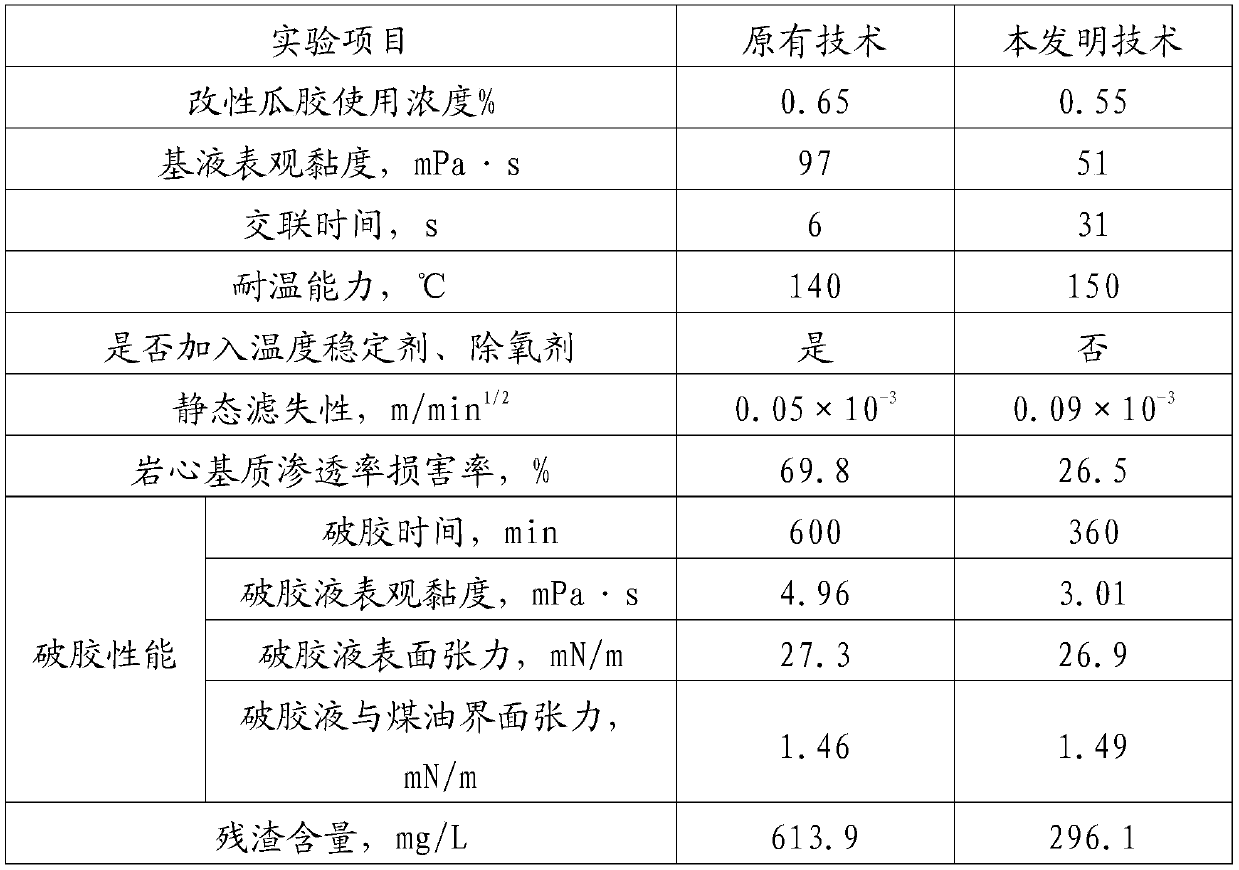

A technology of synergist and seawater, which is applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of poor temperature resistance and large addition amount of fracturing fluid, and achieves improved temperature resistance and swelling speed. , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: The preparation method of the sea-based fracturing fluid synergist, normal temperature and pressure, stirring, adding 60kg of clear water, 25kg of ethylenediaminetetramethylene phosphate sodium, and 25kg of glycerin in the reactor and fully mixing in proportion to form Uniform solution to make synergist.

Embodiment 2

[0018] Embodiment 2: The preparation method of the sea-based fracturing fluid synergist, normal temperature and pressure, stirring, adding 50kg of clear water, 20kg of ethylenediaminetetramethylene phosphate sodium, and 15kg of glycerin in the reactor and fully mixing in proportion to form Uniform solution to make synergist.

Embodiment 3

[0019] Embodiment 3: The preparation method of the sea-based fracturing fluid synergist, normal temperature and pressure, stirring, adding 50kg of clear water, 25kg of ethylenediaminetetramethylene phosphate sodium, and 25kg of glycerin in the reactor and fully mixing in proportion to form Uniform solution to make synergist.

[0020] Embodiment 3 is the best embodiment, and it will be described by taking Embodiment 3 as an example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com